High temperature photoelectric sensor

A photoelectric sensor and high-temperature technology, applied in the direction of electric radiation detectors, etc., can solve the problems that the measurement accuracy cannot meet the requirements, the application limit of photoelectric thermometers, and the upper limit of temperature measurement cannot be exceeded, etc., so that it is easy to form an industrial automatic control system and use And the effect of low maintenance cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

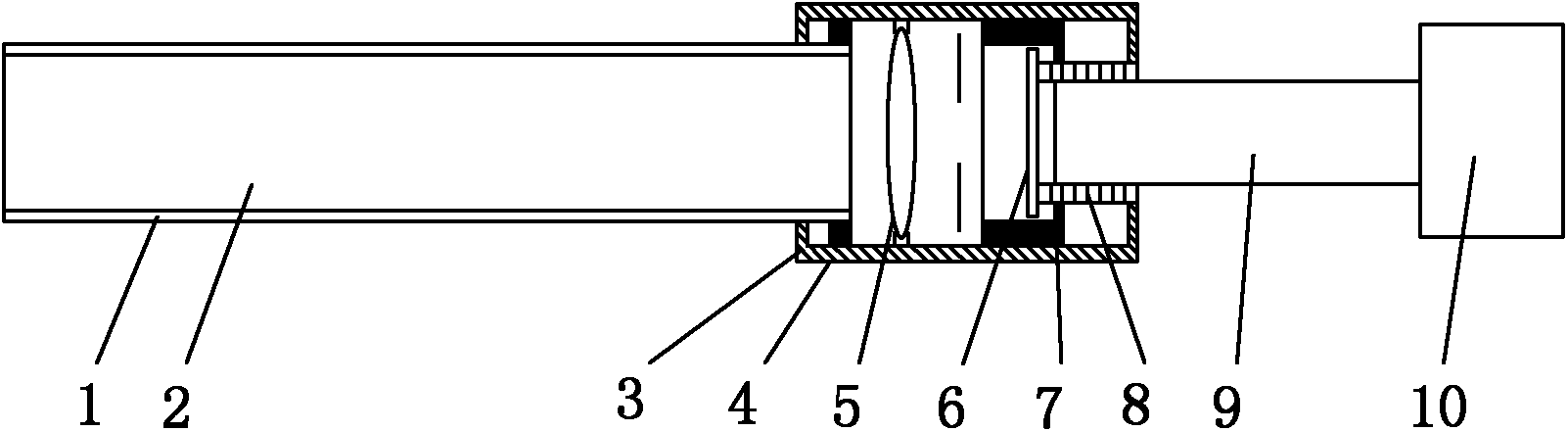

[0025] like figure 1 As shown, the present invention includes a high-temperature conductor composed of a high-temperature cavity tube 1 and a high-temperature conduction tube 2, a metal casing 4 with both left and right side walls open, fixed in the metal casing 4 and concentrating and concentrating the light source to be measured. The optical lens group 5 for guiding light, the filter 6 arranged in parallel on the right side of the optical lens group 5 and performing spectrum selection on the light emitted by the light source to be measured, the optical fiber 9 fixed on the opening on the right side of the metal shell 4, and The right end of the optical fiber 9 is connected to the photoelectric conversion device 10 and the fastening device 7 arranged in the metal casing 4 . The left end of the high-temperature conduction tube is connected to the light source to be measured, and the right end of the high-temperature conduction tube passes through the left opening of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com