High-pressure well-mouth continuous feeding device

A dosing device and high-pressure technology, which is applied in wellbore/well parts, cleaning equipment, earthwork drilling and production, etc., can solve the problems of the difficulty of accurately grasping the period of periodic dosing and washing wells, the unpredictability of the precipitation rate of colloid and asphaltenes, and the increased To solve problems such as operating costs, achieve the effects of convenient and quick installation and disassembly, inhibit precipitation and aggregation, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

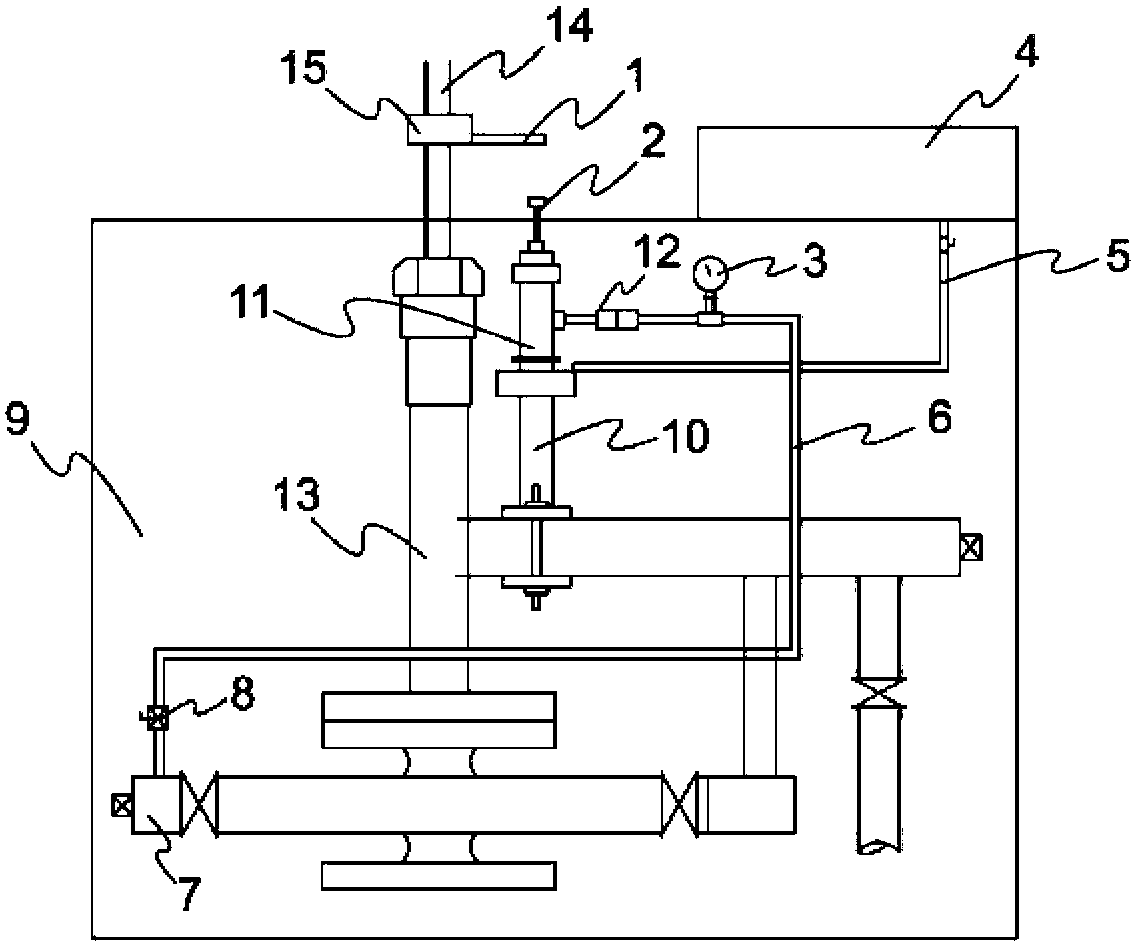

[0016] In order to better understand the purpose, structural features and functions of the present invention, the structure, working process and functions of the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

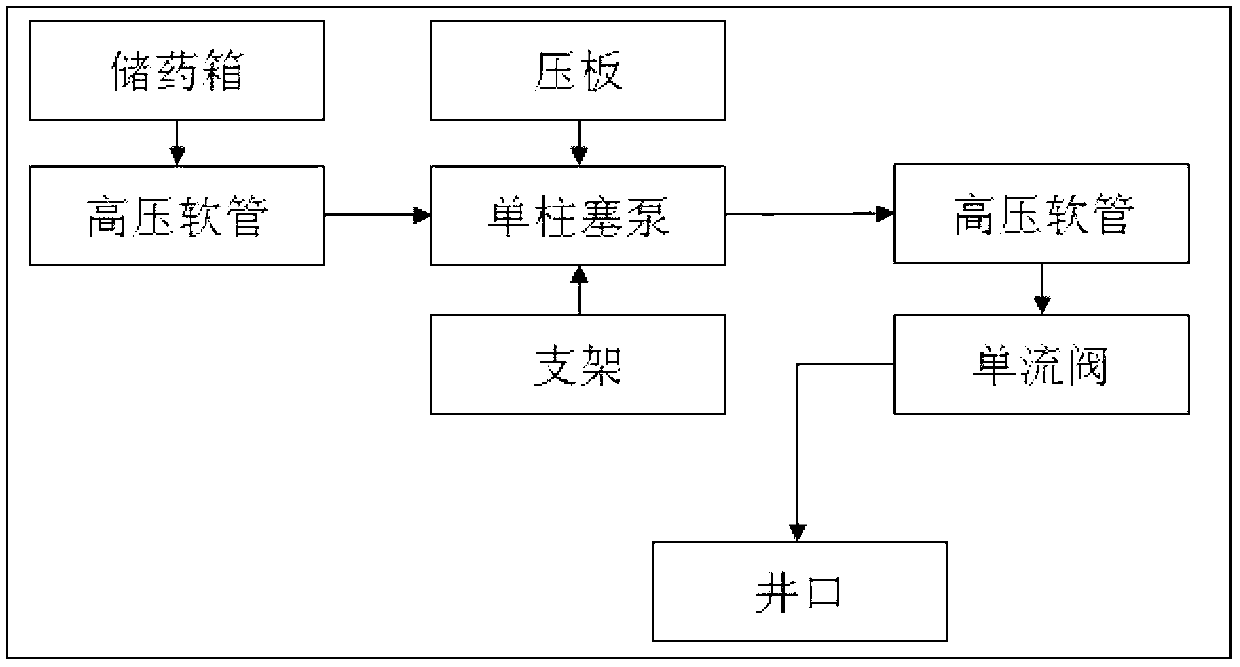

[0017] Such as figure 2 As shown, the high-pressure wellhead continuous dosing device of the present invention is fixed at the high-pressure wellhead 13 by a fixing bracket. Specifically, the pump fixing cylinder 10 and the fixing bracket connect the pump barrel 11 of the single plunger pump of the dosing device fixed on the wellhead; the high-pressure wellhead has a polished rod 14 of the pumping unit, and the pressing plate 1 is fixed on the polished rod 14 of the pumping unit through a square clip 15, and the pressing plate 14 fixed on the polished rod is driven by the pumping unit when it moves up and down. Pressing plate 14 presses single plunger pump adjustment rod when descending, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com