Self-resetting frame joint

A beam-column node and self-resetting technology, which is applied to building components, earthquake resistance, construction, etc., to achieve the effect of simple scheme, self-resetting shock absorption control effect, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

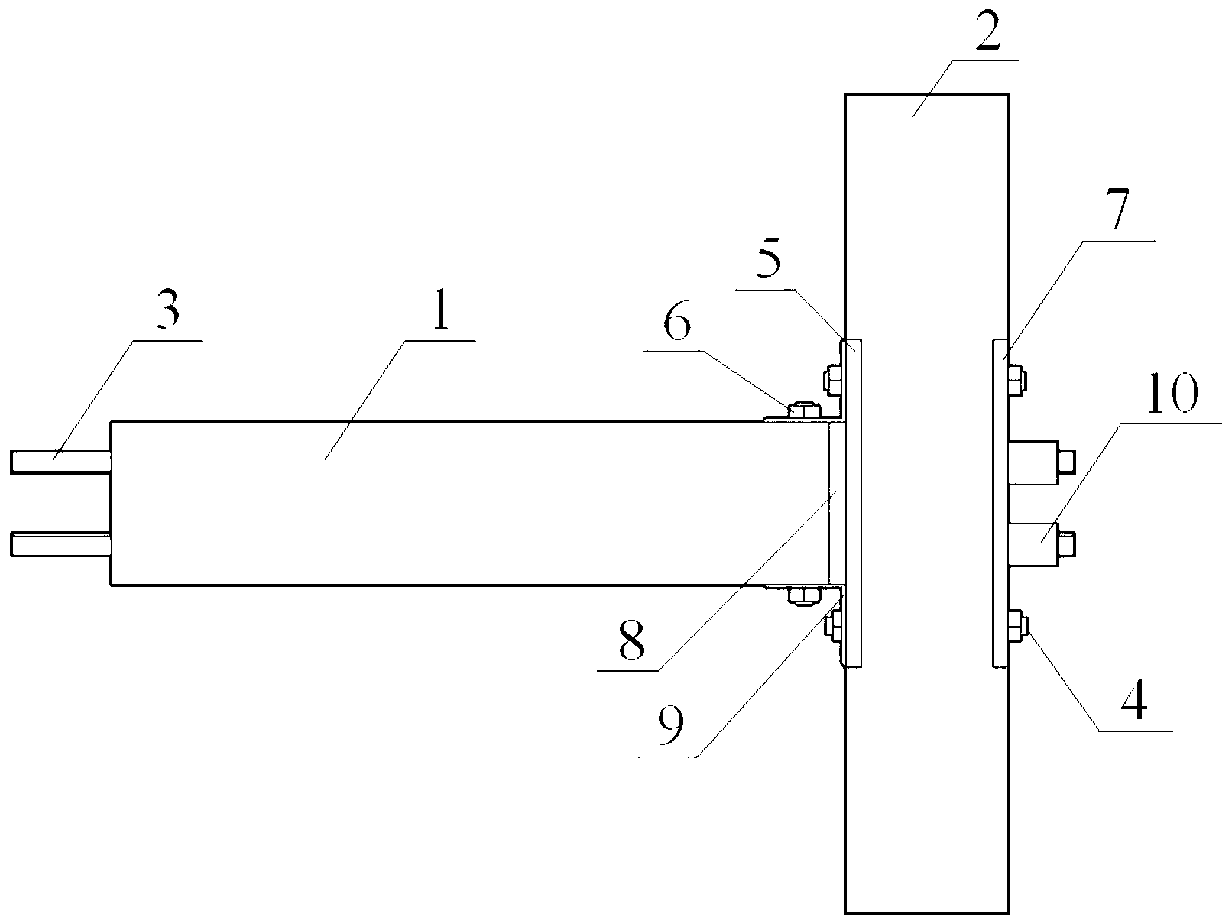

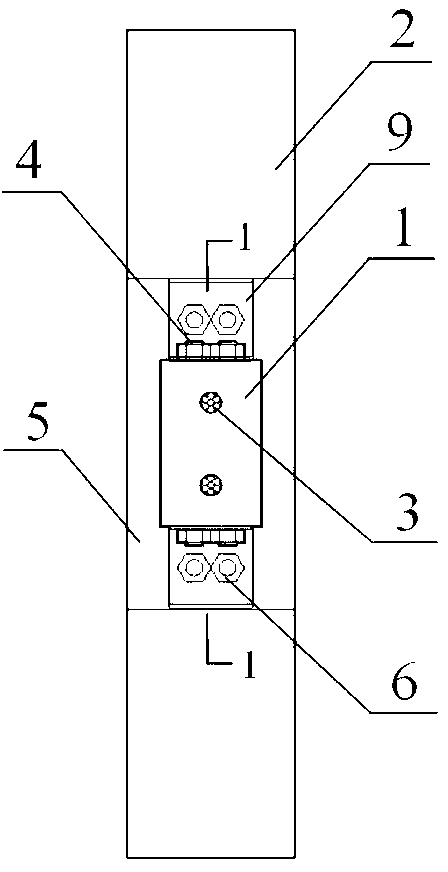

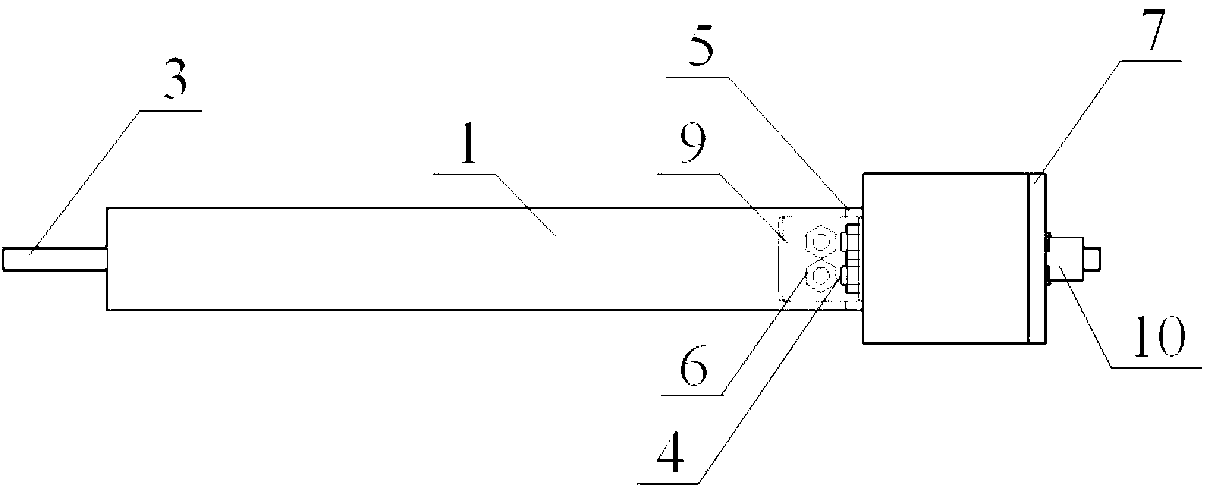

[0042] The beam-column joint of the self-resetting frame adopts a cast-in-place construction method. A self-resetting frame beam-column joint, including a concrete beam 1 and a concrete column 2, the concrete beam 1 and the concrete column 2 are connected by an unbonded low-relaxation prestressed steel strand 3 and an angle steel 9, and the end of the concrete beam 1 is provided with a Three steel plates 8, the first steel plate 5 and the second steel plate 7 are provided near the beam side and the back side of the concrete column, and the unbonded low-relaxation prestressed steel strand 3 passes through the third steel plate 8 at the beam end and the first steel plate at the column side 5. Use the anchor 10 to anchor on the outside of the second steel plate 7 on the side of the column. The angle steel 9 is connected with the concrete beam 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com