Maotai-flavour liquor treatment method

The technology of a Maotai-flavored liquor and its processing method is applied in the production field of Maotai-flavored liquor, which can solve problems such as unsatisfactory effects, and achieve the effects of ensuring the stability of the liquor body, increasing the yield, and having an elegant aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

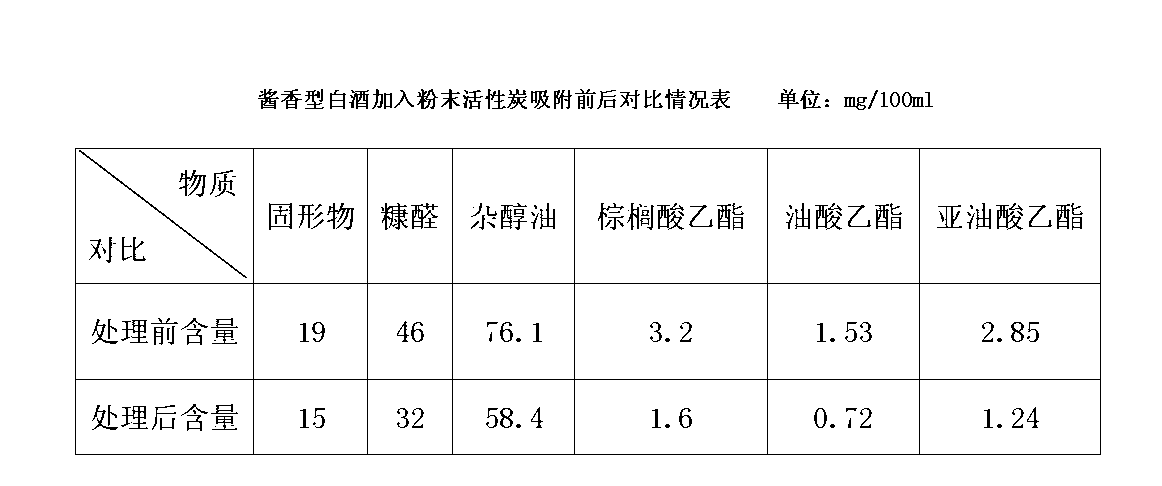

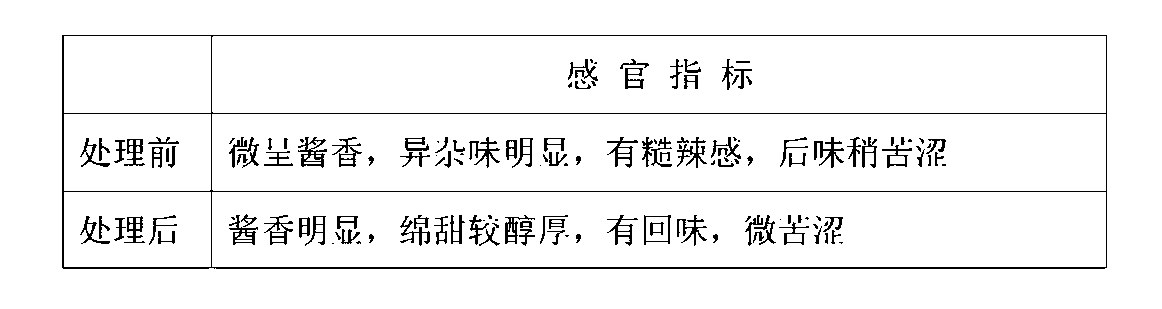

[0020] (1) The use of powdered activated carbon: Add activated carbon equivalent to 1.5‰ of the liquor body weight, that is, 1.5Kg, into the Maotai-flavored liquor, with a pore size of 4nm, let it stand for 24 hours, take a small sample, and observe the degree of suspension or sedimentation of the activated carbon in the liquor. If the activated carbon basically precipitates in the wine body, then add activated carbon equivalent to 1.25‰ of the wine body weight, that is, 1.25Kg of activated carbon with a pore size of 4nm, let it stand for 48 hours, and filter. Utilize the pore structure and chemical composition of activated carbon to absorb organic matter and aldehydes such as fusel oil, furfural, dimethyl sulfide, etc. The association with ethanol molecules accelerates the aging of the wine body, removes the peculiar smell and bitterness in the wine, and achieves the effect of accelerating the aging of the wine. (See figure 1 )

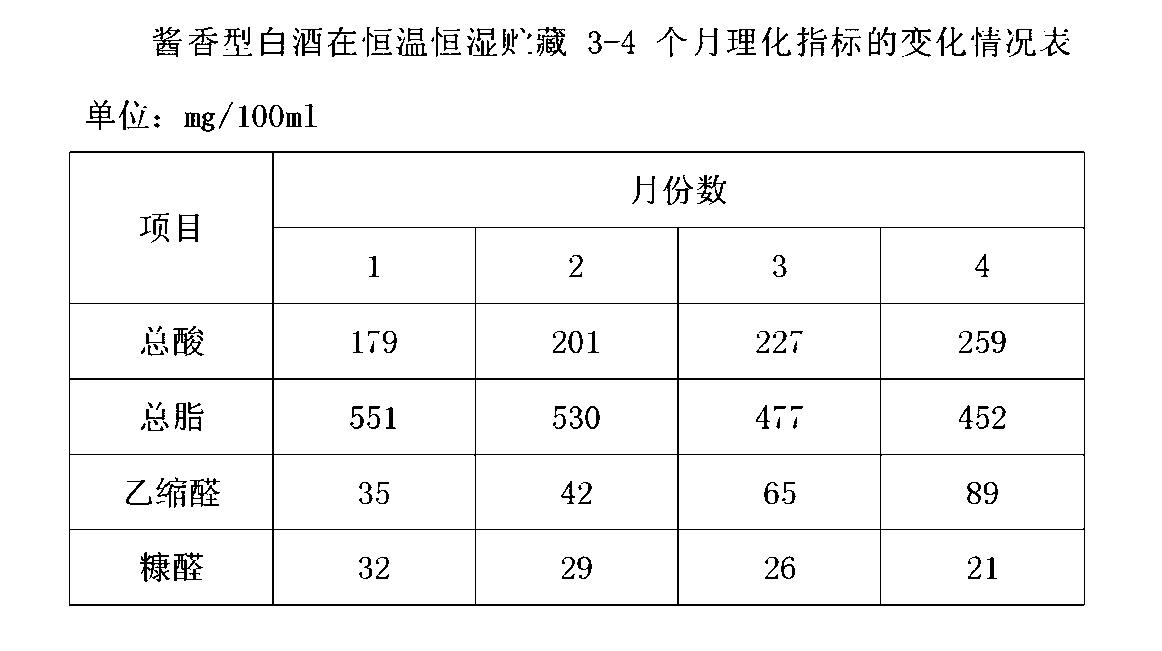

[0021] (2) Storing at constant temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com