A composite core production line and its production process

A production line and composite core technology, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve problems affecting production costs, excessive paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

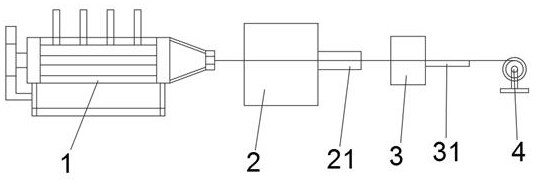

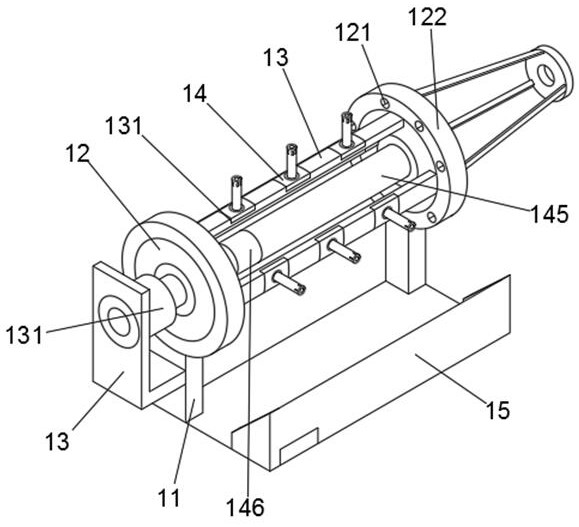

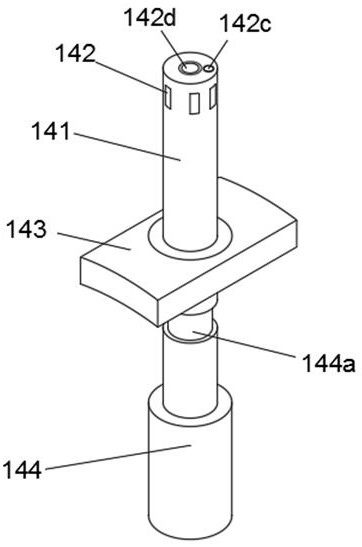

[0026] Example. Please refer to Figure 1-6 , a composite core production line and a production process thereof, comprising the following preparation processes:

[0027] S1 Winding: wind the multi-core cable through the frame twisting machine 1, and the frame twisting machine 1 uses pneumatic to automatically replace the wire reel;

[0028] S2 traction: 2 pairs of cables equipped with traction devices are used to pull the cables at a constant speed, and at the same time, the cables are squeezed through the pipe 21 to make the cables more rounded;

[0029] S3 enamelling: use the enamelling machine 3 to carry out the corresponding enamelling treatment on the cable that has passed through S2 and wrap it with a layer of round shell, and then perform the corresponding cooling treatment through the cold water tank 31;

[0030] S4 Rewinding: Control the angle of cable offset through the adjusting device, and then cooperate with the rewinding device 4 to carry out the coiling process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com