Bidirectional air intake device of biomass gasifier

A two-way air inlet and gasification furnace technology, which is applied in the field of household furnaces or stoves, can solve the problems of uneven wind field and wind pressure in the furnace, affect the ventilation performance of the furnace, and the gasifier cannot work continuously for a long time, and achieve uniform wind pressure , Guarantee the effect of gas production and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

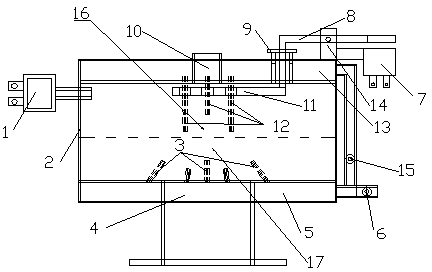

Embodiment 1

[0013] The igniter 1 is connected to the furnace 2, the 8 upper air ducts 12 are connected to the upper air duct 13, the 8 lower air ducts 3 are connected to the lower air duct 5, the feed port 4 is connected to the bottom of the furnace 2, and the upper air duct 13 and the lower air duct 5 are connected at the same time It is connected with the damper 6, an upper air pipe damper 15 is arranged between the upper air passage 13 and the damper 6, the material level sensor 7 is connected with the furnace 2, the material level sensing rod 8 is connected with the furnace 2 through the material level sensing rod support 14, and the One end of the level sensing rod 8 is a material level detection plate 11 , the sealing sheet 9 is connected with the material level sensing rod 8 , and the gas outlet 10 is connected with the furnace mouth of the furnace 2 .

[0014] The damper 6, the upper air duct damper 15, the upper air duct 13 and the upper air duct 12 are sequentially connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com