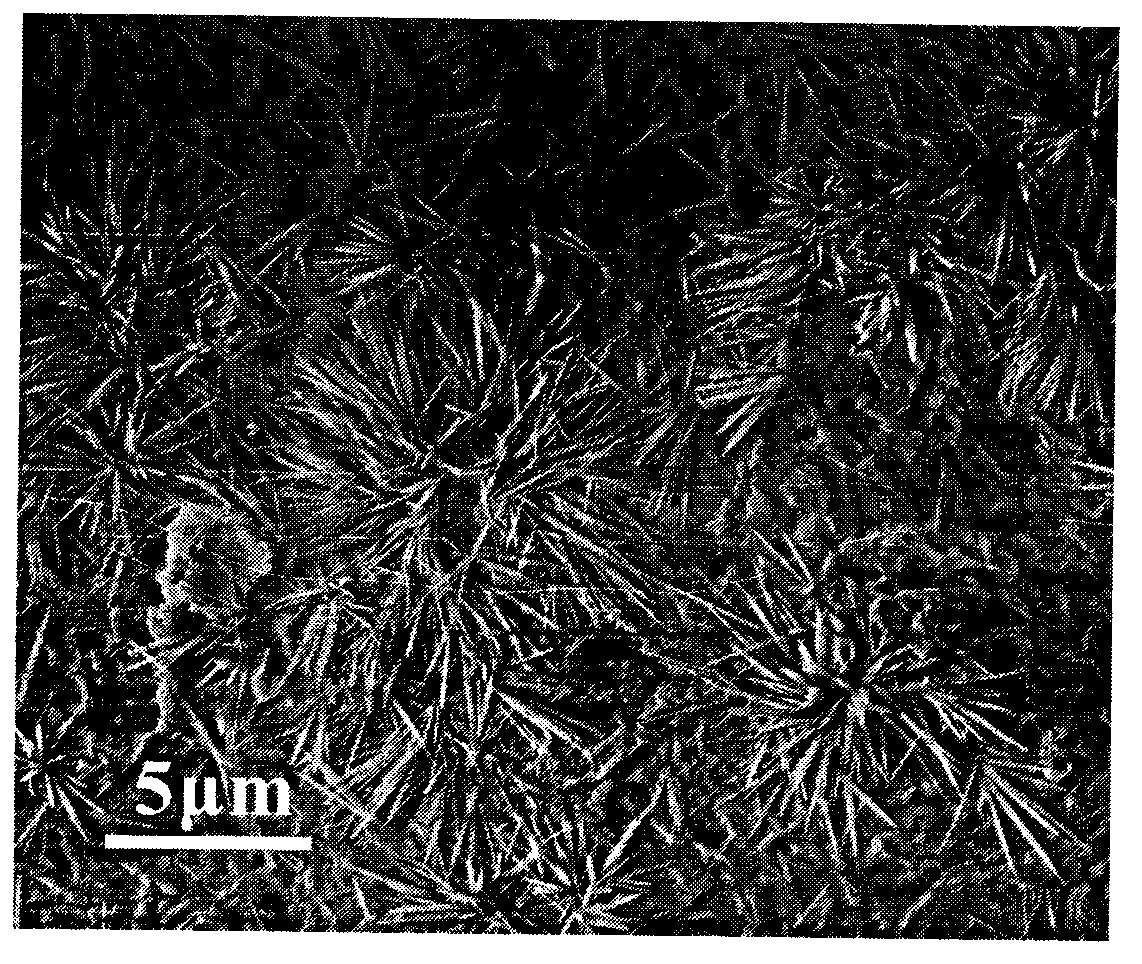

Nanoneedle-structure manganese vanadate self-cleaning paint

A technology of structural manganese vanadate and nano needles, which is applied in the direction of coating and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

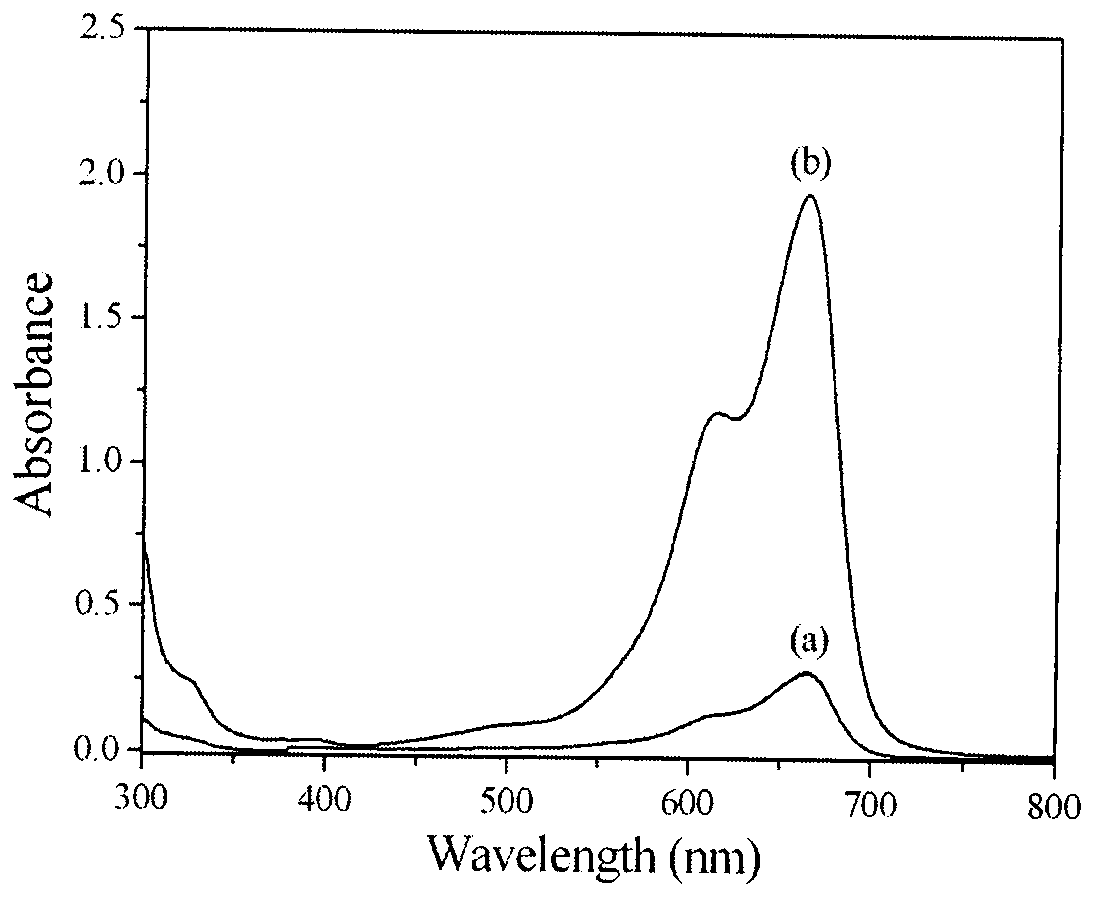

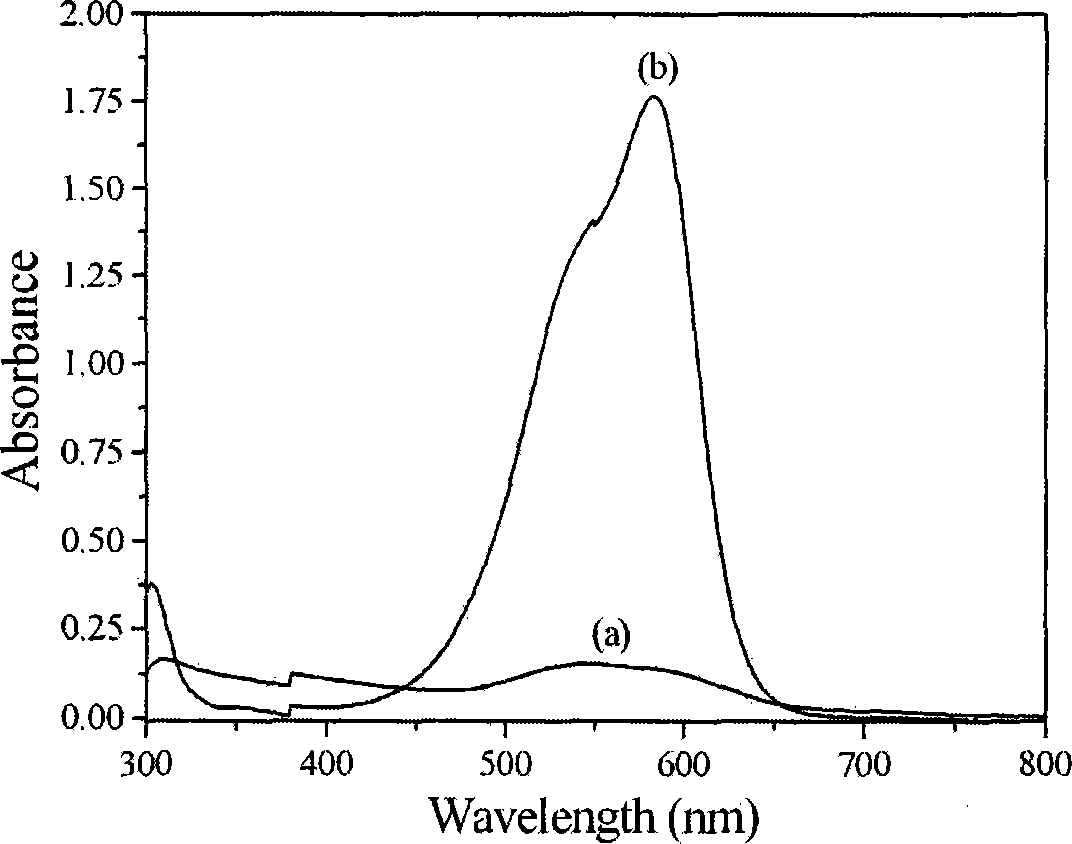

Image

Examples

Embodiment 1

[0022] Embodiment 1: determine that the mass percent of nano needle-like structure manganese vanadate self-cleaning coating is composed as follows: nano-needle structure manganese vanadate 35%, vinegar acrylic emulsion 17.9%, water 35%, nano silicon dioxide 10%, alcohol ester -120.1%, 0.5% of tributyl phosphate, 0.5% of 10% sodium hexametaphosphate aqueous solution, 0.5% of ethylene glycol, and 0.5% of polyurethane.

Embodiment 2

[0023] Embodiment 2: determine that the mass percent of nano-acicular structure manganese vanadate self-cleaning coating is composed as follows: nano-acicular structure manganese vanadate 40%, vinegar acrylic emulsion 20.05%, water 30%, nano silicon dioxide 8%, alcohol ester -120.1%, 0.6% of tributyl phosphate, 0.6% of 10% sodium hexametaphosphate aqueous solution, 0.6% of ethylene glycol, and 0.5% of polyurethane.

Embodiment 3

[0024] Embodiment 3: determine that the mass percent of nano-acicular structure manganese vanadate self-cleaning coating is composed as follows: nano-acicular structure manganese vanadate 37%, vinegar acrylic emulsion 15.9%, water 33%, nano silicon dioxide 12%, alcohol ester -120.1%, 0.5% of tributyl phosphate, 0.5% of 10% sodium hexametaphosphate aqueous solution, 0.5% of ethylene glycol, and 0.5% of polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com