Damping structure for decelerating dust collector wire winding wheel

A technology of damping structure and winding wheel, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., and can solve the problems of fast recovery of power cords, power cord plugs hurting people, and entangled cords, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

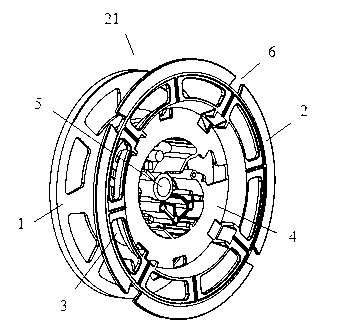

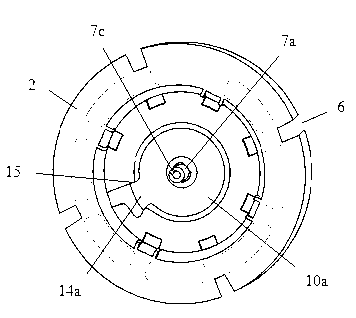

[0060]A damping structure for the deceleration of the reel of the vacuum cleaner, including the reel 21 formed by the left reel 1, the right reel 2 and the hollow bobbin 3 winding the power cord between them, the shaft tube 5 in the center of the bobbin 3, and the right The annular groove 4 on the outer surface of the wheel disc 2 is provided with an oil damping structure 8 combined with the connecting shaft 7 .

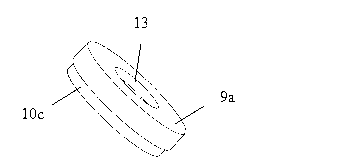

[0061] figure 2 It is a schematic diagram of the installation structure of the winding wheel and oil damping in the present invention, image 3 is a schematic diagram of the three-dimensional structure of the upper cover in the oil damping structure, Figure 4 is the schematic diagram of the three-dimensional structure of the friction disc in the oil damping structure, Figure 5 is a schematic diagram of the three-dimensional structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com