Active carbon filling vibration bed of iodine adsorber

A technology of iodine adsorber and activated carbon, which is applied in the field of iodine adsorber activated carbon filled vibrating bed, which can solve the problems of broken nuclear-grade activated carbon, poor controllability, large production dust, etc., and achieve the effect of purifying the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

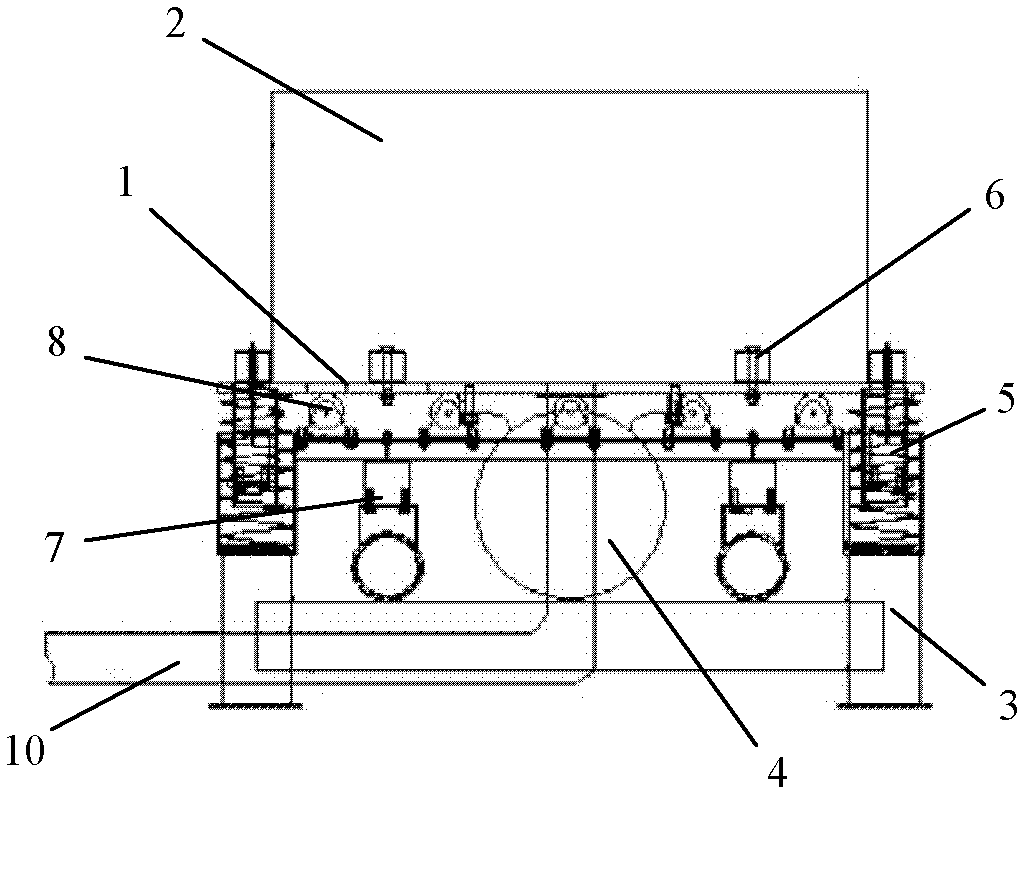

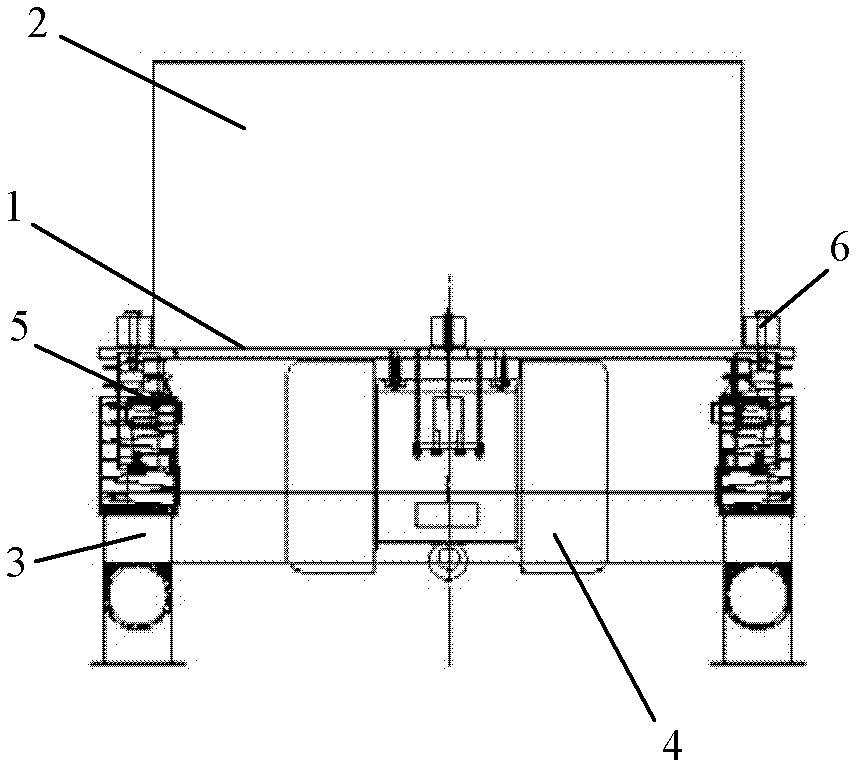

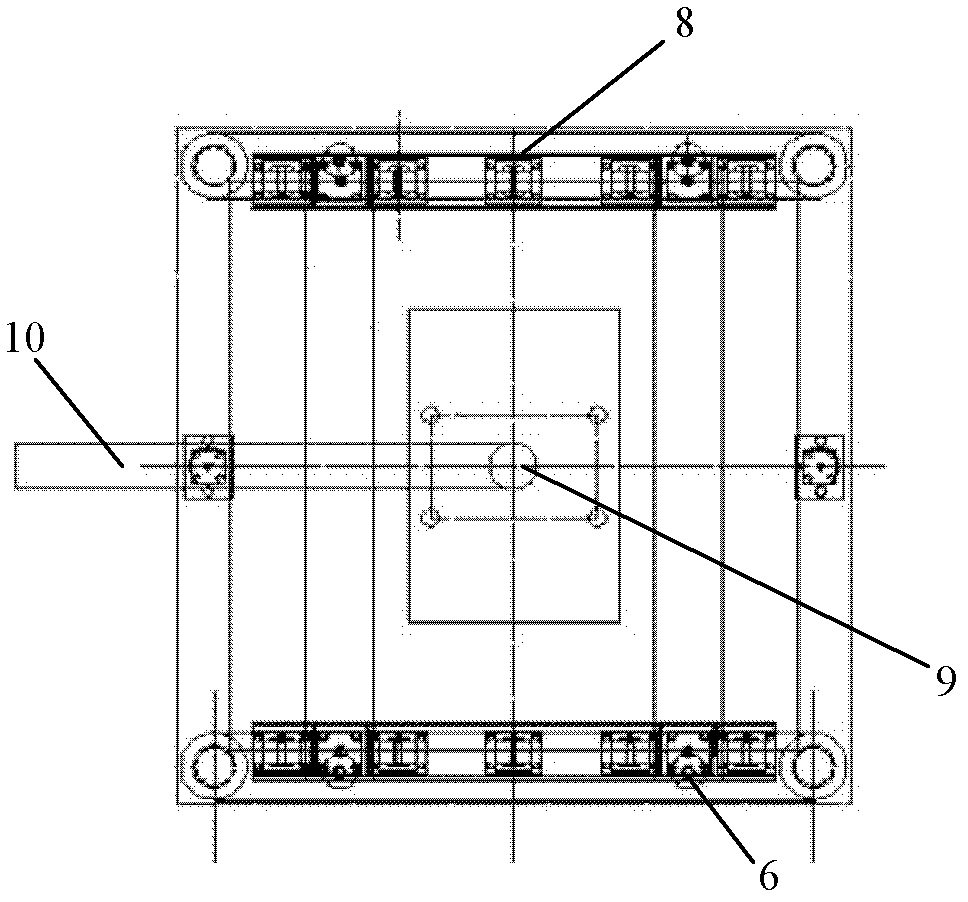

[0016] like Figure 1-3 As shown, the vibrating part of the iodine adsorber activated carbon filling vibrating bed provided by the present invention includes a vibrating bed surface 1 for setting the iodine adsorber housing 2, the vibrating bed surface 1 is arranged on the support 3, and the vibrating bed surface 1 is arranged below A vibrating motor 4, a damping spring 5 is arranged between the vibrating bed surface 1 and the support 3. The vibrating bed surface 1 is rectangular, and damping springs 5 are respectively installed on the four corners of the vibrating bed surface, and the bottom ends of the damping springs 5 are seated on the support. The vibration equipment filled with iodine adsorber activated carbon adopts motor vibration, with adjustable amplitude and optional frequency. The vibrating motor 4 is connected to the support 3 with v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com