Automatic probe delivery and draw-out system capable of converter steelmaking endpoint parameter detection and liquid steel sampling and telescopic pipe assembly

A technology of parameter detection and converter steelmaking, applied in the direction of manufacturing converters, etc., can solve the problems of plant height, large space required for auxiliary gun equipment, large cost investment, etc., to achieve accurate workstations, reduce installation space, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

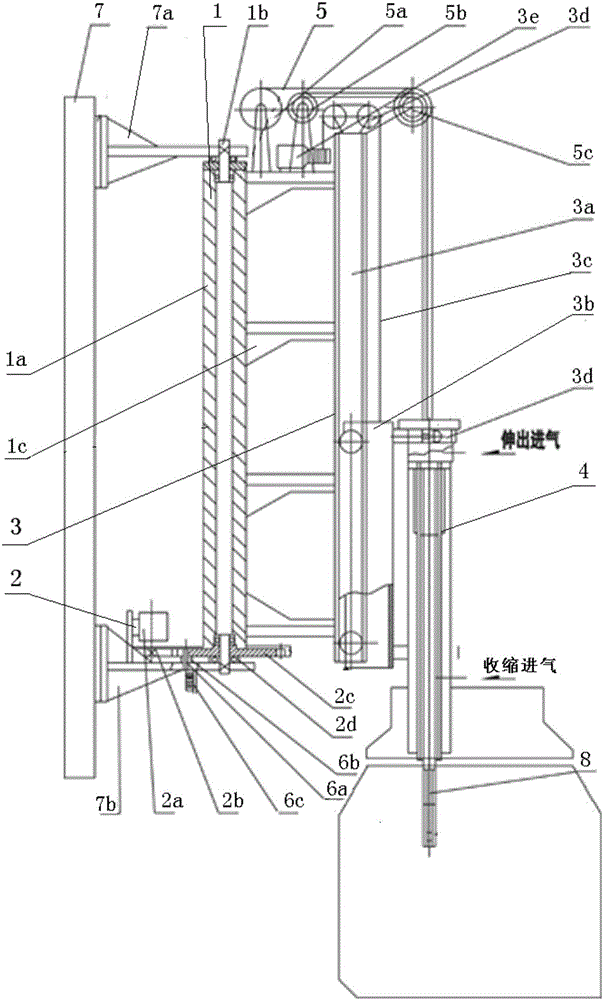

[0029] figure 1 It is a schematic diagram of an embodiment of the present invention:

[0030] A converter steelmaking end point parameter detection and molten steel sampling probe automatic delivery system of the present invention includes a rotary frame and a lifting part, the rotary frame 1 is connected with the rotary drive 2, the rotary frame 1 is connected with the lifting part 3, and the lifting part 3 is connected Install the multi-layer telescopic tube assembly 4, the lower end of the multi-layer telescopic tube assembly 4 is used as the connection end of the composite probe; the multi-layer telescopic tube assembly 4 has a hollow cavity as the composite probe pipeline channel, and the composite probe pipeline retractable mechanism 5 is installed on the upper part of the slewing frame 1, The lifting drive of the lifting part 3 is also installed on the slewing frame 2 upper ends.

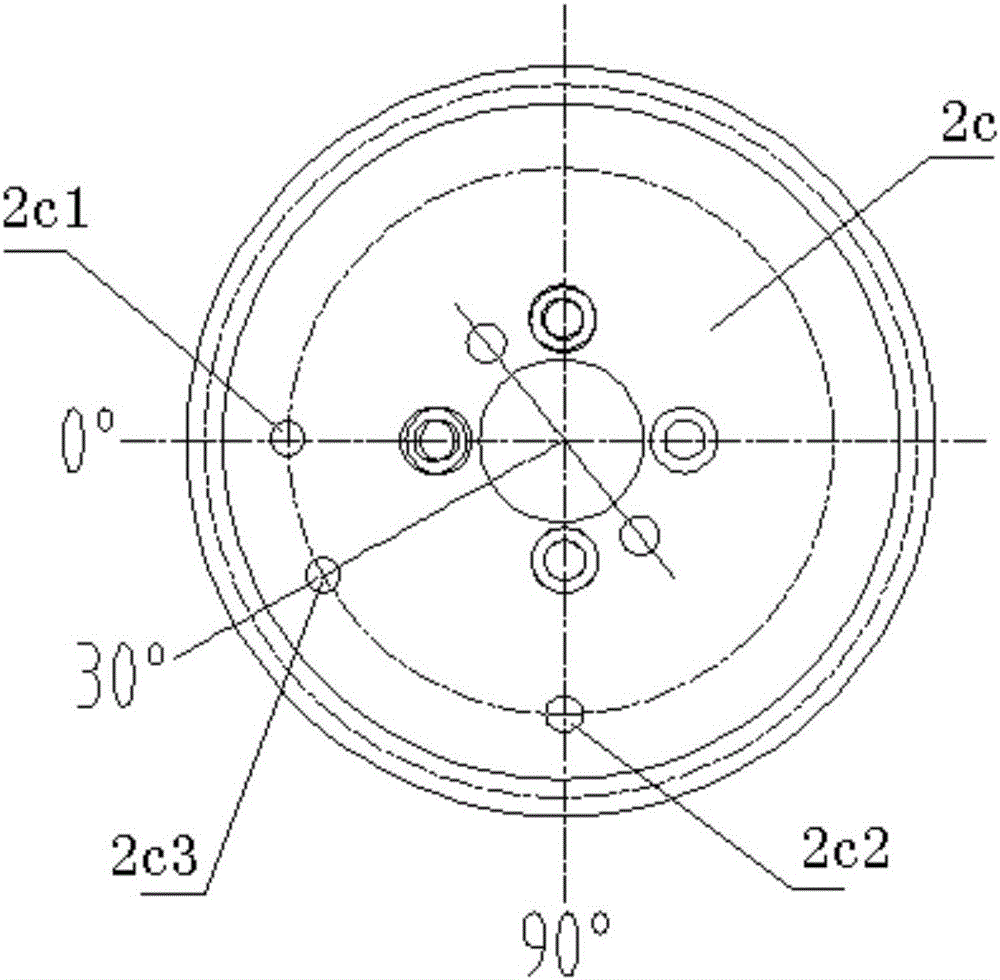

[0031] The lifting part 3 includes a vertical guide rail 3a connected to the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com