Control circuit for heater with variable resistance associated with sensor for detecting oxygen in exhaust gases

A control circuit and oxygen sensor technology, applied in electrical control, non-electric variable control, temperature control, etc., can solve problems such as power dissipation, heater efficiency loss, and error increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

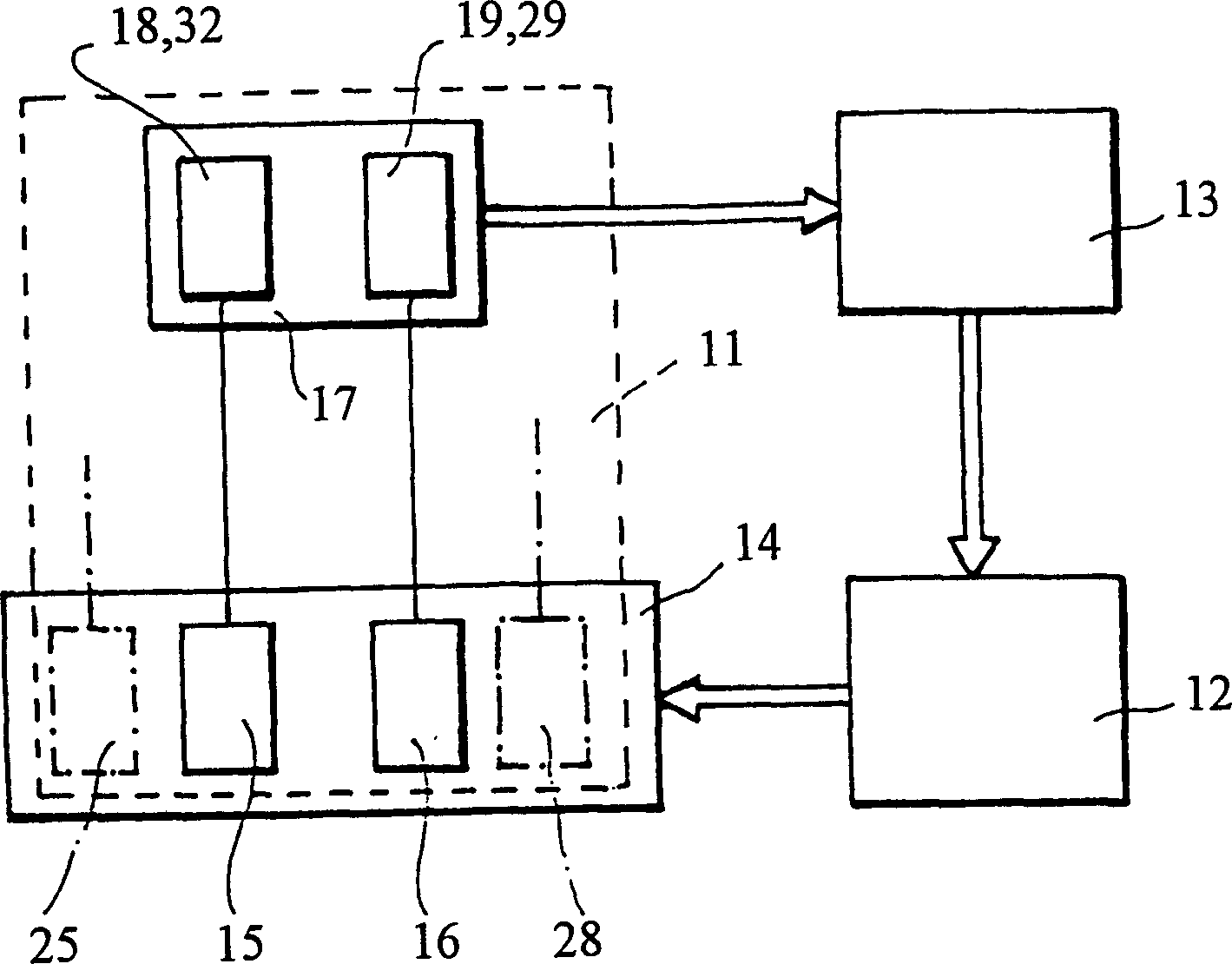

[0028] figure 1 A system 11 for controlling emissions from an internal combustion engine 12 of a vehicle is represented in block diagram form.

[0029] This system 11 works in conjunction with a fuel injection system 13 and a catalytic converter 14 . It comprises: a sensor 15 (lambda probe) for detecting oxygen in the exhaust gas associated with an electric heater 16 ; and an electronic control unit 17 . A microprocessor 18 is included.

[0030] The lambda probe 15 can provide a signal indicative of the oxygen content in the exhaust gas.

[0031] The electronic unit 17 uses these signals to adjust the injection system 13 to achieve the optimum air-oil ratio.

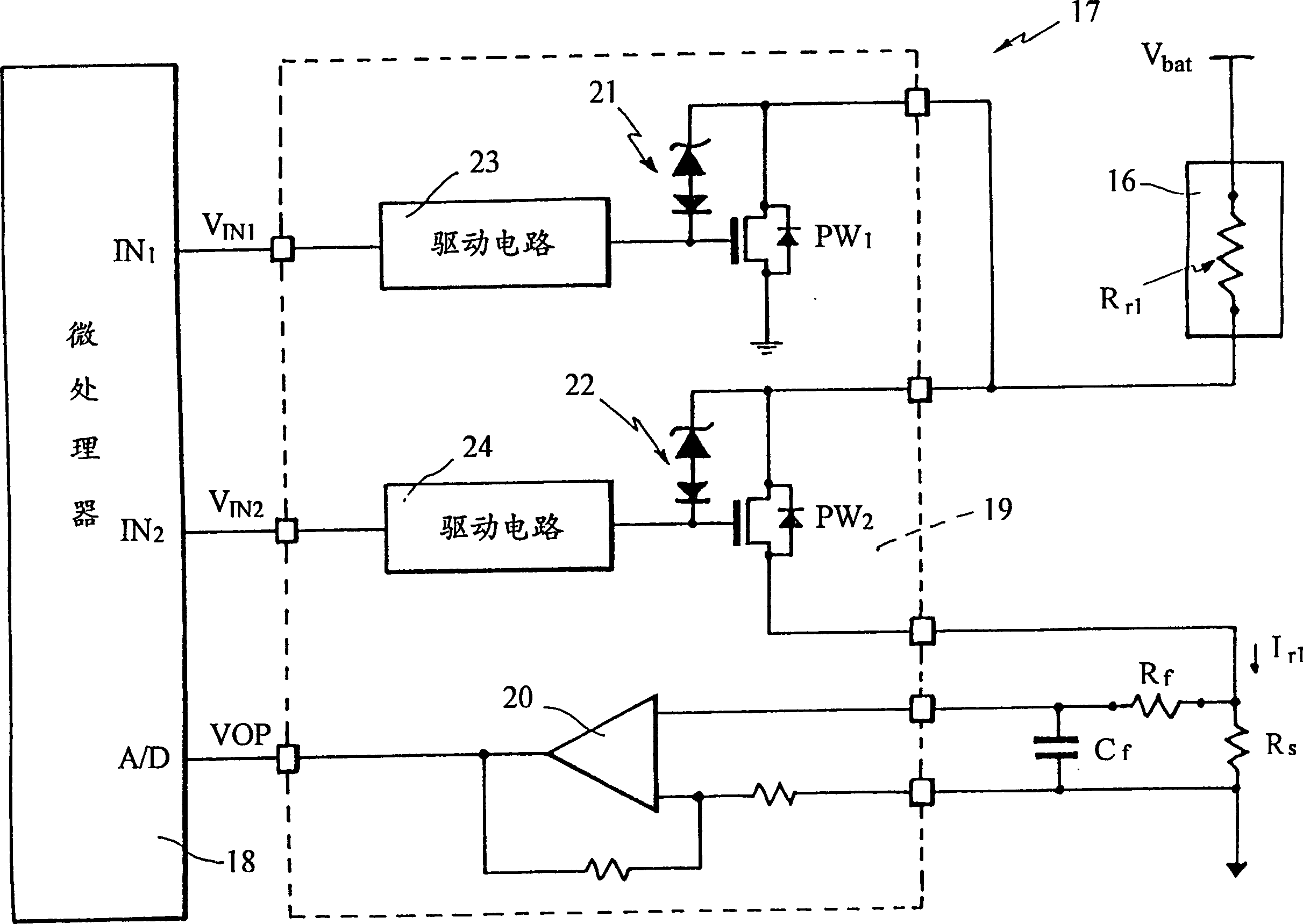

[0032] The probe 15 is installed in the converter 14 together with an electric heater. This heater consists of a resistor R r1 (See image 3 ), whose first terminal is connected to one terminal of a DC voltage source, such as the positive terminal of a car battery.

[0033] The electronic unit 17 includes a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com