Broken belt catching device

A catcher and belt-breaking technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of limited promotion in a wide range, unsatisfactory capture effect, and high cost of transformation, so as to avoid accidents. , Easy to install, great effect of capturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

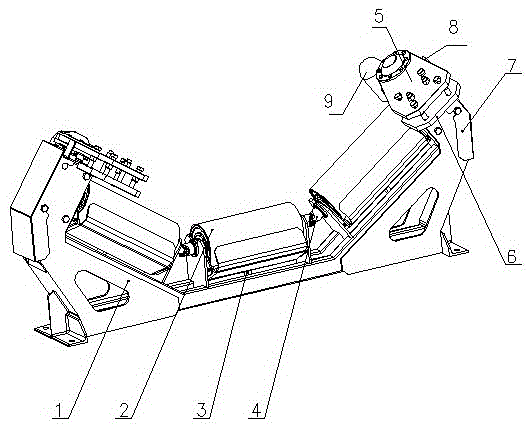

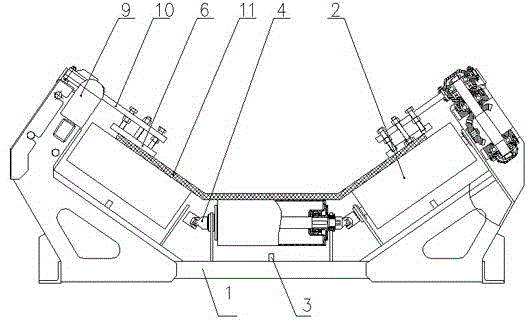

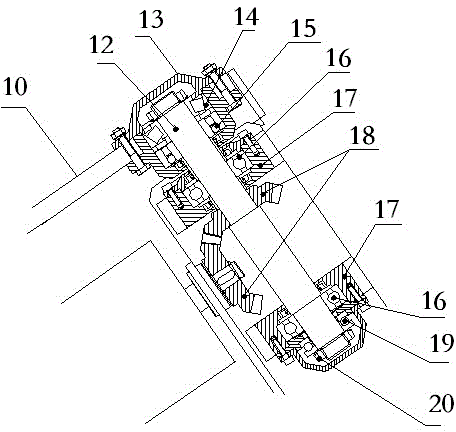

[0027] Such as figure 1 , 2 , 3, and 4, a broken belt catcher of the present invention includes a roller bracket 1, and three backstop idler rollers 2 are arranged on the idler bracket 1, and the backstop idler 2 includes a roller body 2-1 and a center Axis 2-2, the central axis 2-2 traverses through the center of the roller body 2-1 and is connected to the roller bracket 1 in rotation, the central axis 2-2 is connected with a brake plate 2-4, and the roller body 2-1 passes through the single The bearing I 2-5 is connected to the central shaft 2-2; the outer ends of the central shaft 2-2 of the backstop idler 2 located on both sides of the idler bracket 1 are driven and connected to a rotatable shaft 12, and the shaft 12 is passed through a single The wedge plate 5 is connected to the bearing II15. The idler support 1 on the outside of the wedge plate 5 is provided with two vertical rollers 9 . The three backstop rollers 2 are connected by universal couplings 4 .

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com