Novel material grinding device

A material and grinding technology, which is applied in grain processing and other directions, can solve the problems of inconvenient installation and maintenance of hydraulic cylinders, large land occupation, and heavy weight, and achieve the effects of saving manufacturing costs, reducing overall weight, and solving large land occupations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

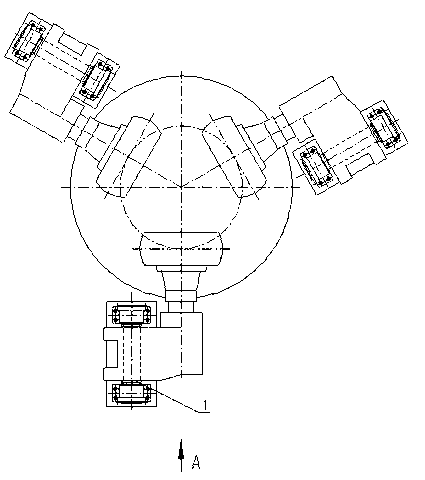

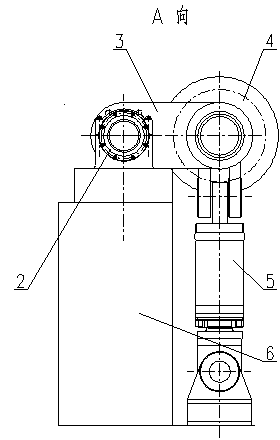

[0011] A new type of material grinding device, including a rotating shaft 1, a bearing seat 2, a rocker arm 3, a grinding roller 4, a hydraulic cylinder 5 and a column 6; the hydraulic cylinder 5 is placed outside the lower part of the rocker arm 3, and the grinding roller 4 is connected to the rocker arm 3 Close to the end of the hydraulic cylinder 5, the rocker arm 3 is tightened by the hydraulic cylinder 5 to make the grinding roller 4 rotate along the rotating shaft 1 as a lever, and the torque is transmitted through the rocker arm 3 to pressurize the grinding roller 4; the rotating shaft 1 passes through the rocker arm 3 On the other end, the two ends of the rotating shaft 1 are covered with bearing seats 2, and the bearing seats 2 are fixed on the upper surface of the column 6. The centerline of the rotating shaft 1 is parallel to the axial centerline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com