Bio-gas hydrogen sulfide removal device by using ion exchange fiber Pall ring for bio-gas purification

An ion-exchange fiber, biogas technology, applied in the directions of gas fuel, gas treatment, separation method, etc., can solve the problems of complex structure, inconvenient production and use, reduced hydrogen sulfide removal efficiency, etc., and achieve simple structure, prolong life, maintain Manage simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

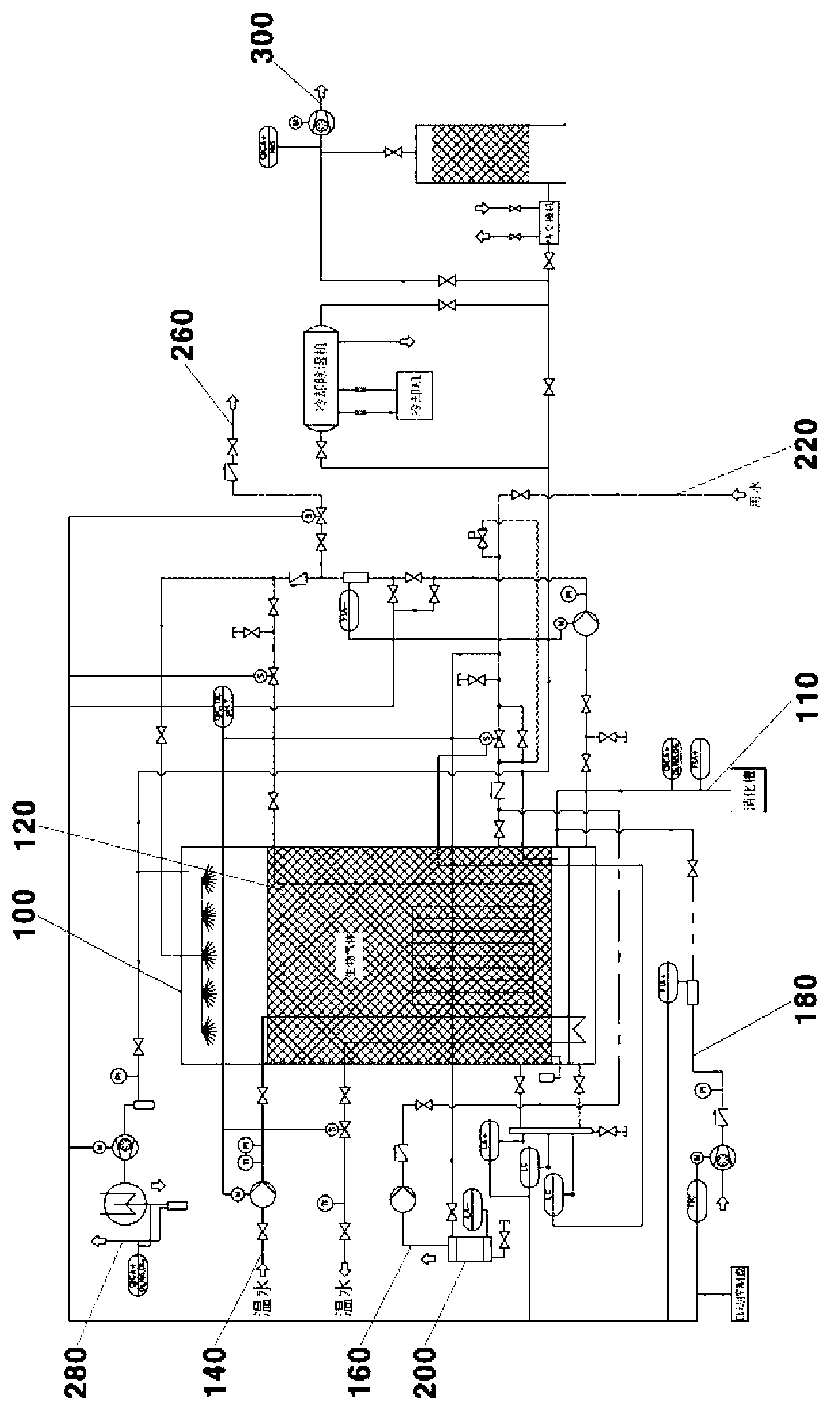

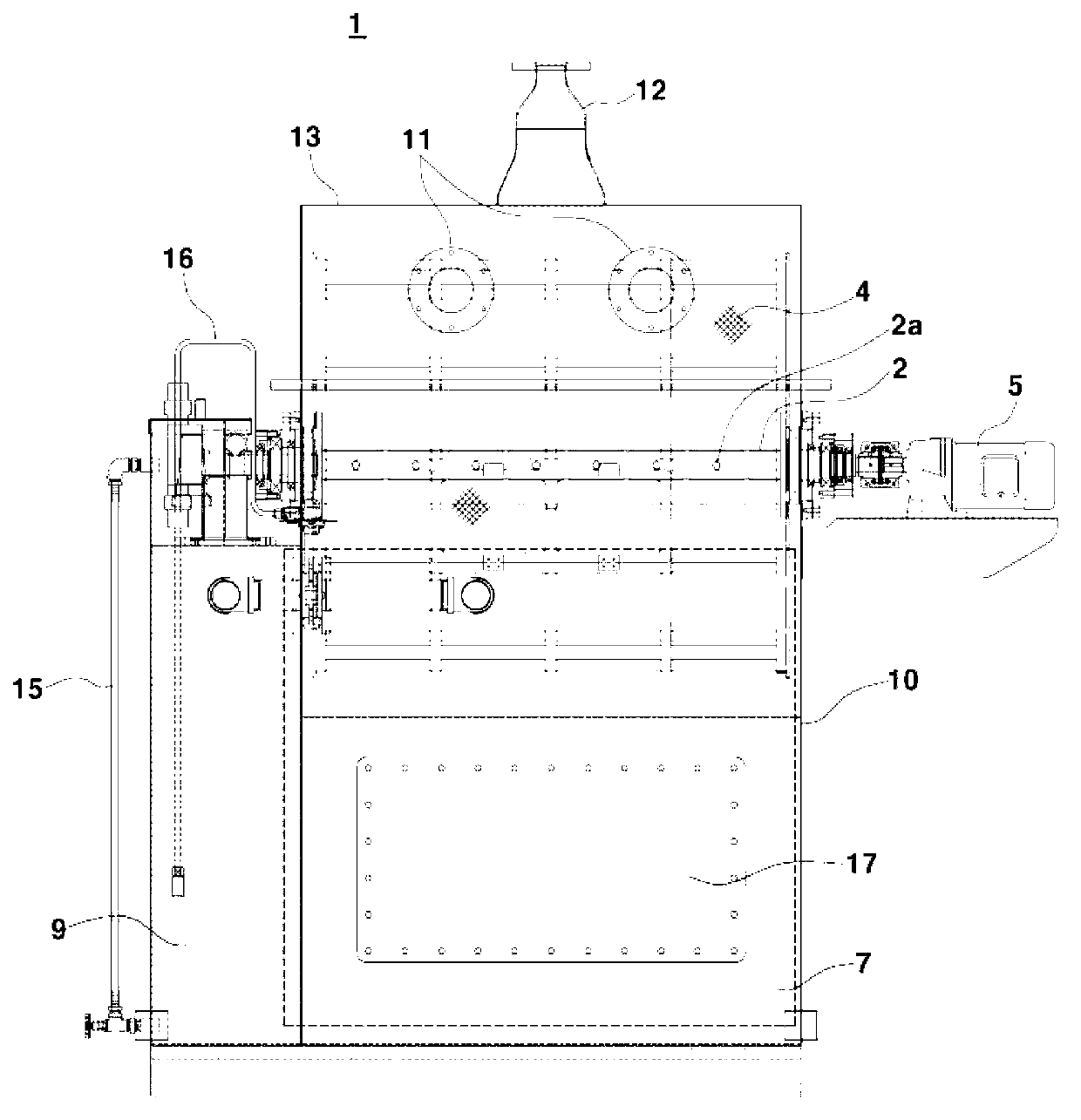

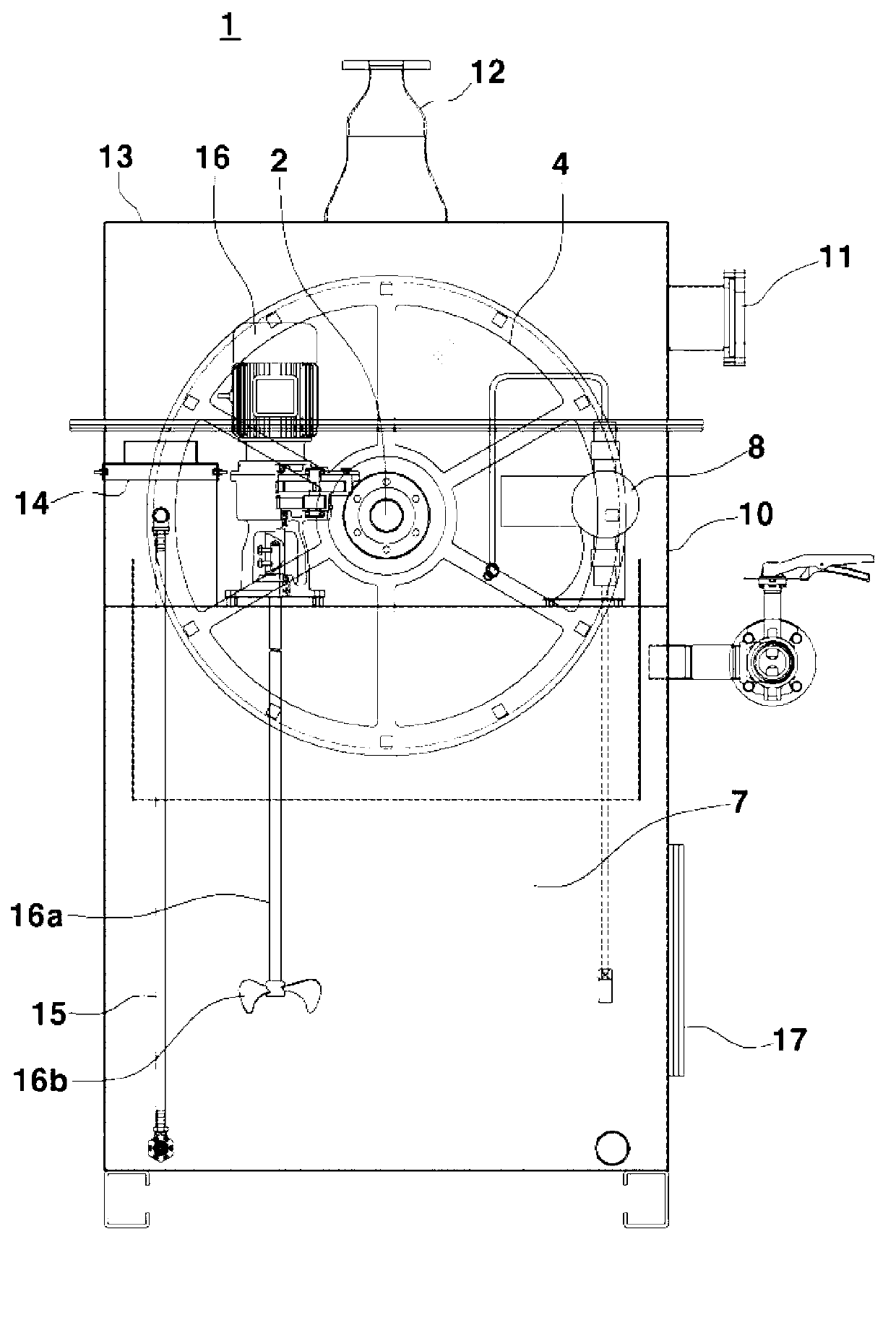

[0048] Hereinafter, the present invention will be specifically described with reference to the drawings.

[0049] figure 2 It is a front view showing the outline of the structure of the hydrogen sulfide removal device for refining biogas according to the present invention, image 3 It is a side view showing the outline of the hydrogen sulfide removal device structure for biogas refining according to the present invention, Figure 4 It is a plan view showing the outline of the structure of the hydrogen sulfide removal device for refining biogas according to the present invention.

[0050] The device 1 for removing hydrogen sulfide from biogas according to the present invention includes a main body 10 , a cover 13 , a net body type drum 4 , a Pall ring 6 , a regeneration liquid tank 7 and a regeneration raw liquid production tank 9 .

[0051] The main body 10 of the hydrogen sulfide removal device 1 configured in this way is constituted by a hexahedron, and the upper part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com