Device used for detecting pressure resistance of ceramic tube

A technology of withstand voltage testing and ceramic tubes, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as the inability to quantify ceramic tube products and the lack of strength testing methods, etc., to achieve a comprehensive test range and guarantee The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

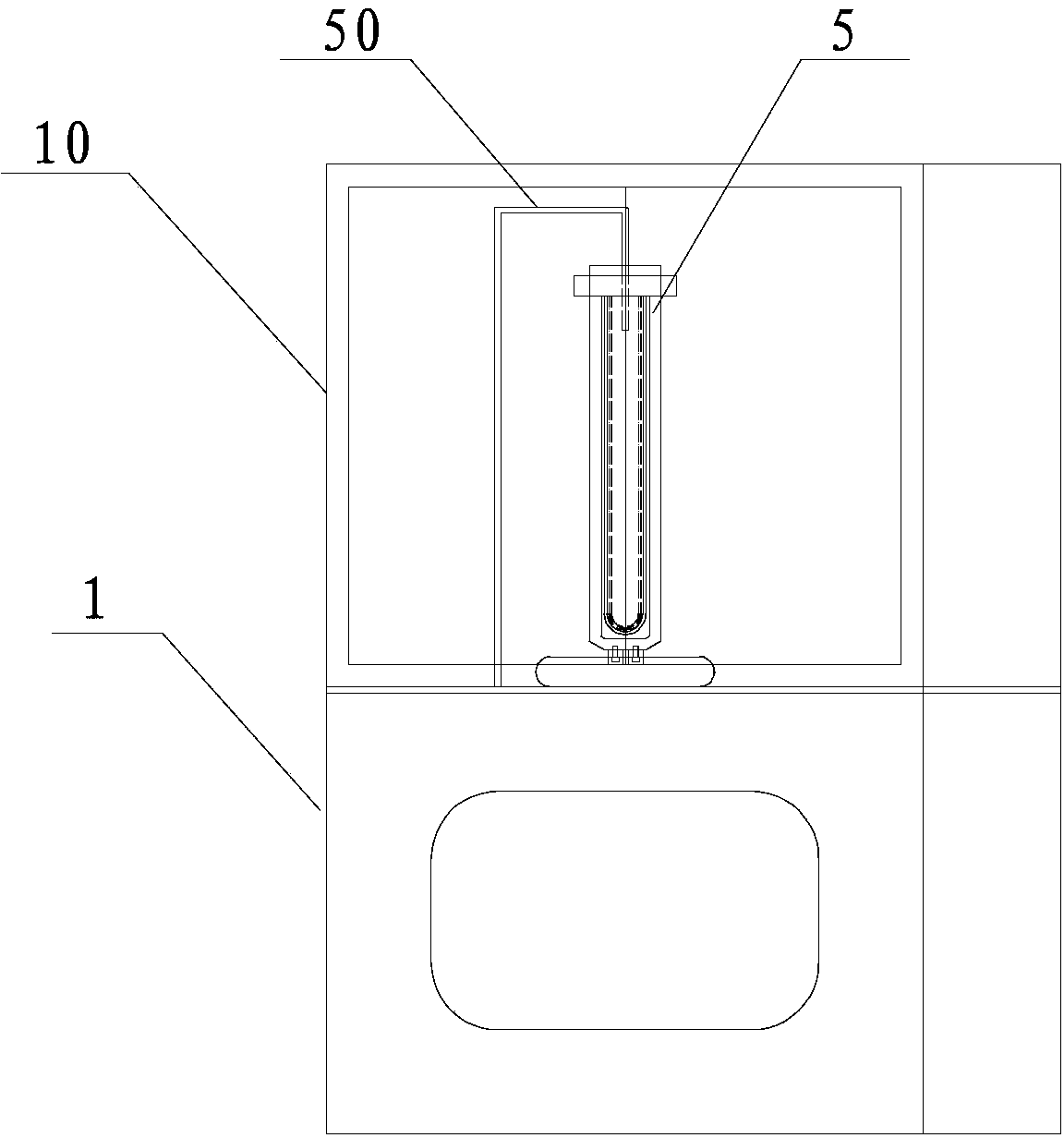

[0024] Please refer to Fig. 1, the pressure-resistant detection equipment for ceramic tube of the present invention includes a casing 4, test fixture 5 and pressurization system, wherein,

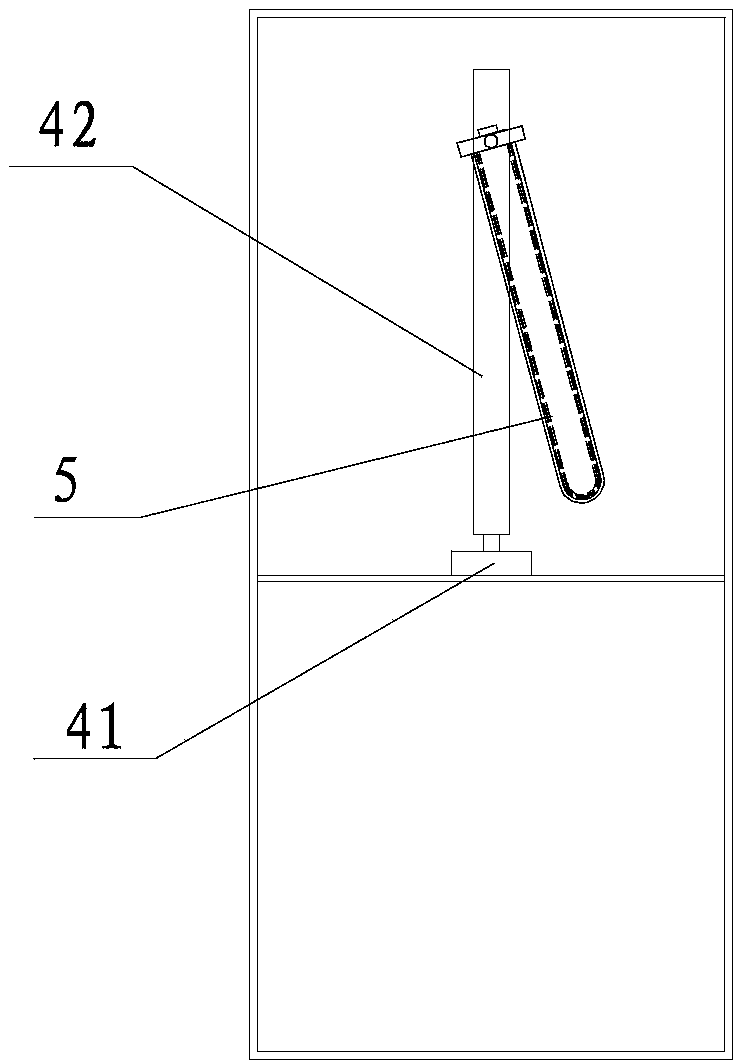

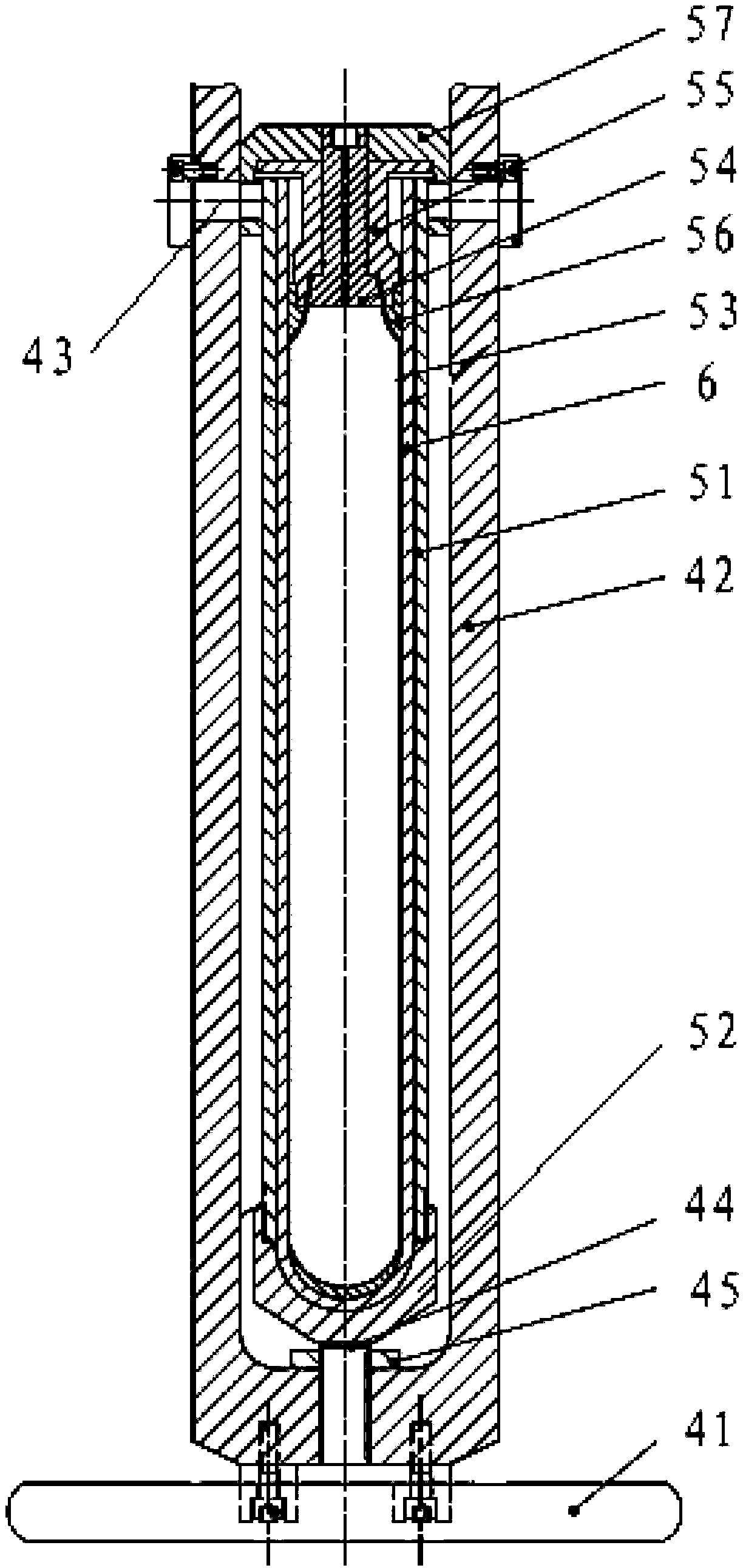

[0025] Casing 4 tops are provided with a test cavity 40, and the inside of this test cavity 40 is provided with base 41 and frame 42, and base 41 is installed on the base plate of test cavity 40; Framework 42 is U-shaped structure, and it is fixed on the upper end of base 41, A bearing 43 is respectively installed on the top of the two side arms of the frame 42, and a threaded through hole is provided in the center of the bottom wall of the frame 42, and a screw rod 44 and a nut 45 are connected in the threaded through hole;

[0026] Test fixture 5 is movably connected on frame 42 by bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com