Electric smelting type pressure type recyclable anchor rod technology

A pressure-type, anchor technology, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of insufficient pull-out resistance of anchor rods, pollution of the surrounding environment, etc., achieve simple and complete recovery, and improve the effect of pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

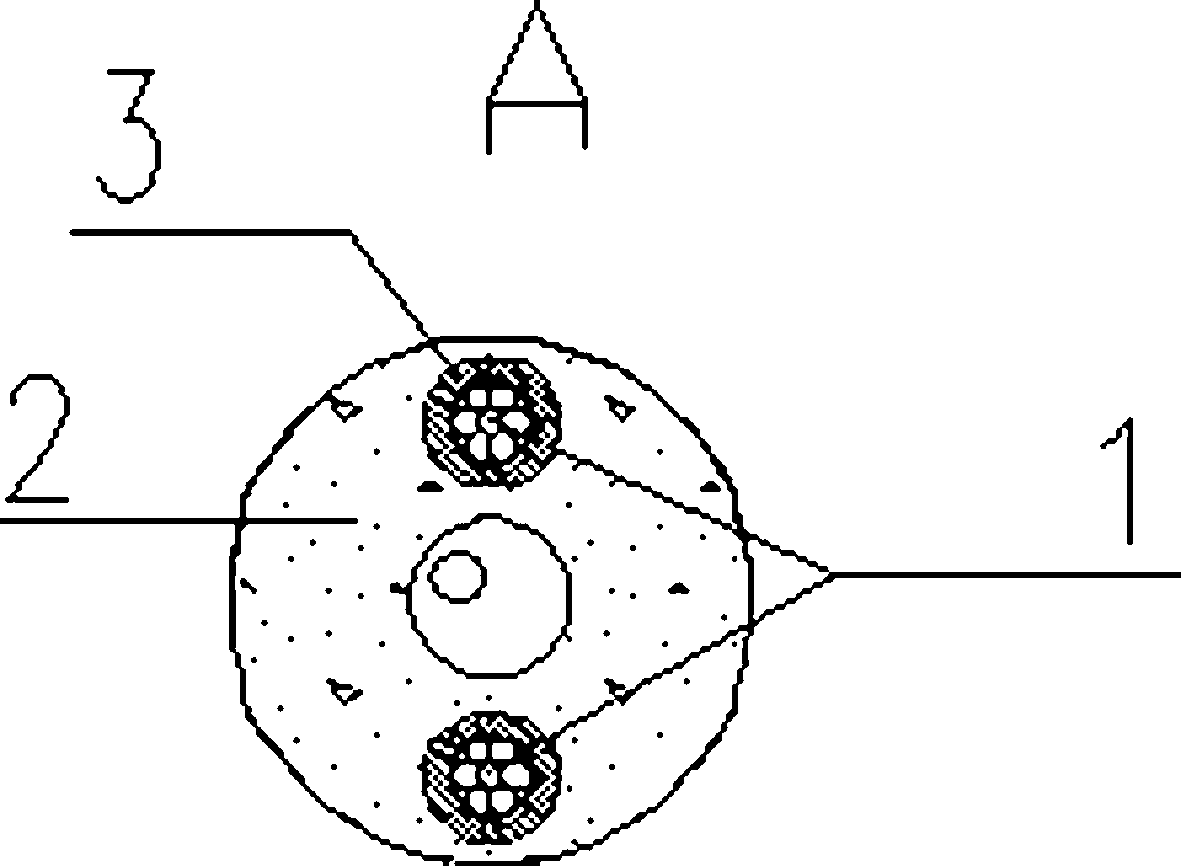

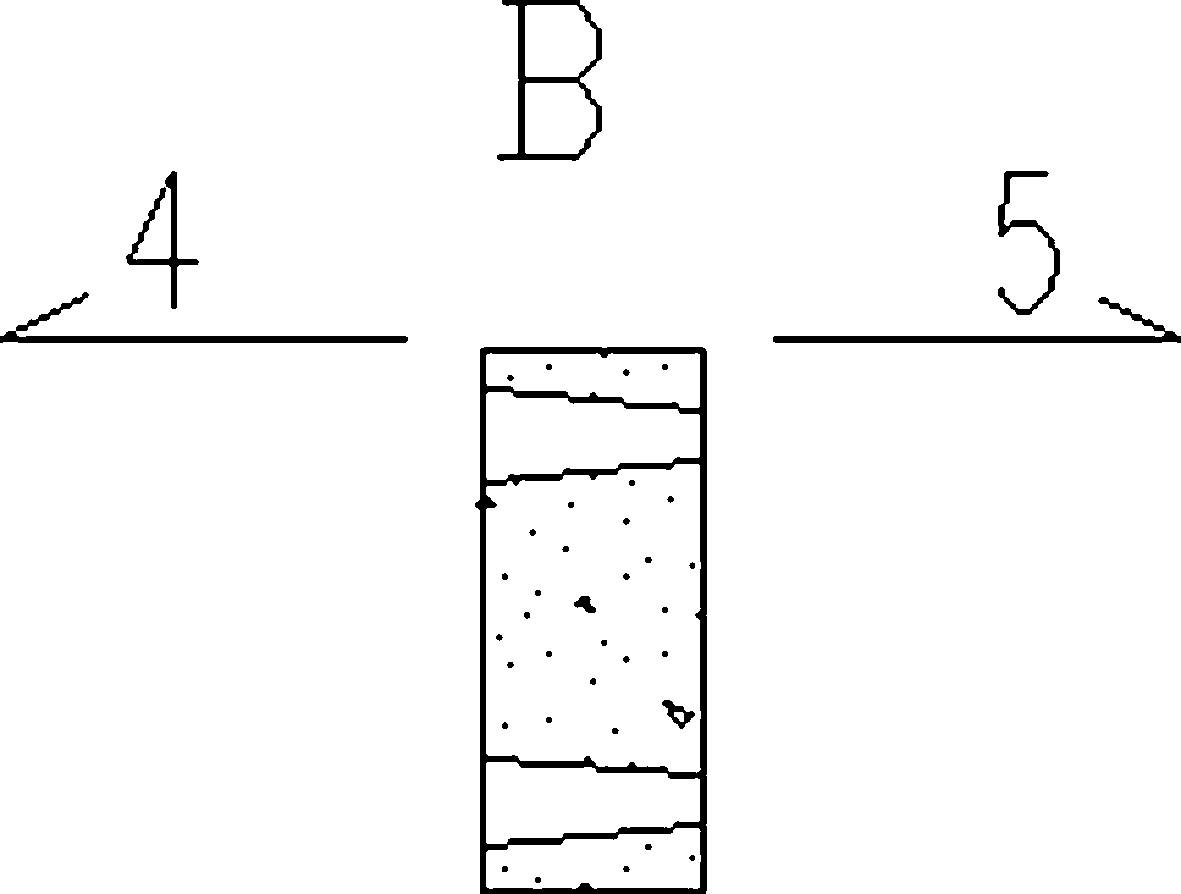

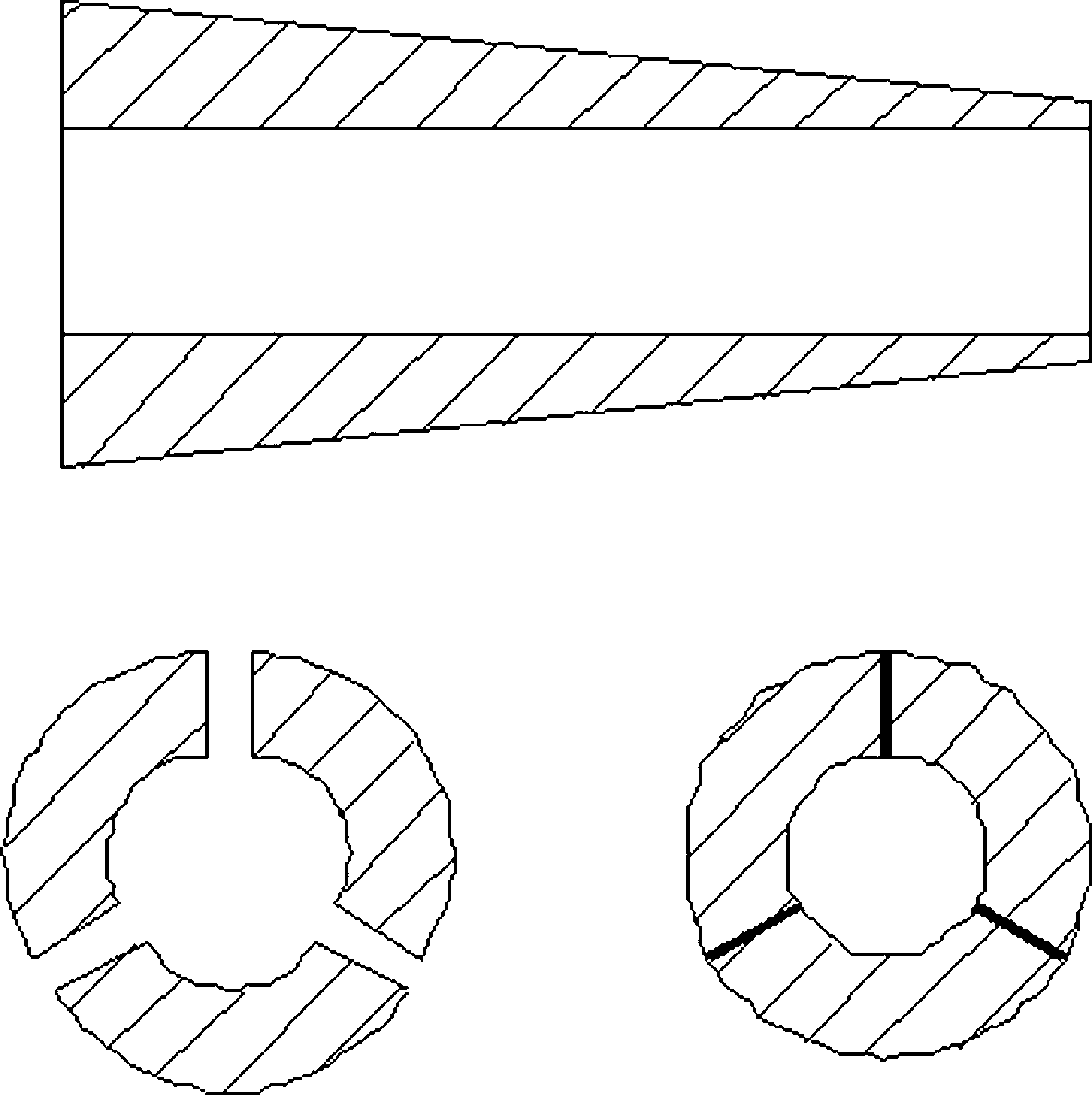

[0030] An electrofusion pressure type recoverable bolt technology, the steps are as follows:

[0031] 1) Drilling and forming holes: Drilling and forming holes on the side wall of the foundation pit (following pipe technology is used in complex strata). After reaching the designed hole depth, take out the drill pipe and evacuate the drilling machine. The hole diameter and hole depth are implemented according to the design requirements;

[0032] 2) Fabrication and installation of electrofusion recyclable bolts;

[0033] 3) Anchor installation: place the prepared electrofusion pressure-type retrievable anchor in the borehole, and pull out the follow-up casing;

[0034] 4) Grouting, tensioning and locking: start the grouting pump, and grout the prepared grout to the anchorage section through the embedded grouting pipe according to the design pressure, flow rate and flow rate. After the grout reaches its age, stretch and lock it according to the design or relevant specification r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com