Method for extracting natural flavor with dimethyl ether

A technology of natural fragrance and dimethyl ether, which is applied in the direction of essential oil/fragrance, fat generation, etc., to achieve the effect of easy promotion, rich particle voids, and increased contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

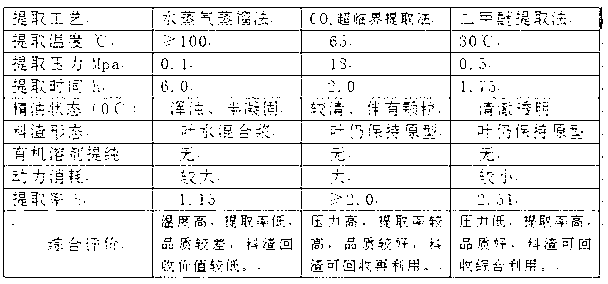

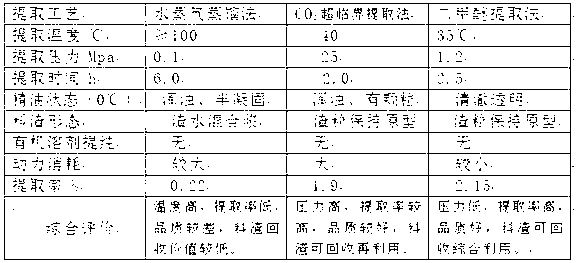

Method used

Image

Examples

Embodiment 1

[0040] a. Pulping: Weigh 50 kg of fresh mint leaves that have been removed from rot and impurities, clean them and put them into a beater, inject 50 kg of clear water, and grind for 0.5 hours to make a slurry;

[0041] b. Slurry drying: put the slurry into the drying box of the vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -30°C, the time is 2h, the vacuum sublimation drying temperature is -25°C, the vacuum degree is -0.09MPa, and it is dried for 5h to obtain Freeze-dried peppermint block 7.5kg, take it out, bag and seal it, and store it in a refrigerator at 4°C for subsequent use;

[0042] c. Spice extraction: Weigh 2 kg of freeze-dried mint leaf block and extract the spice components with 6 kg of dimethyl ether. The operating conditions are extraction temperature 30 ° C, extraction pressure 0.5 Mpa, extraction time 35 min; after the extraction, the dimethyl ether extract After filtering and removing particulate impurities, pump it into the evapor...

Embodiment 2

[0050] a. Pulping: Weigh 50 kg of fresh roses, remove rot and impurities, put them into a beater, inject 75 kg of clear water, and refine for 0.8 hours to make a slurry;

[0051] b. Slurry drying: put the slurry into the drying box of the vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -30°C, the time is 2h, the vacuum sublimation drying temperature is -25°C, the vacuum degree is -0.082MPa, and dried for 5h Finally, 8.2 kg of freeze-dried rose lumps were obtained, which were taken out, bagged and sealed, and stored in a refrigerator at 4°C for subsequent use;

[0052] c. Fragrance extraction: Weigh 2 kg of dry rose block and extract the fragrance components therein with 8 kg of dimethyl ether. The operating conditions are extraction temperature 40°C, extraction pressure 0.7Mpa, and extraction time 50 minutes; after the extraction, the dimethyl ether extract is filtered to remove particulate impurities, and pumped into the evaporation tank, and the mat...

Embodiment 3

[0060] a. Pulping: Weigh 50 kg of cumin seeds, remove rot and impurities, put them into a beater, inject 100 kg of clear water, and grind for 1 hour to make a slurry;

[0061] b. Slurry drying: put the slurry into the drying box of the vacuum freeze dryer for pre-freezing, the pre-freezing temperature is -30°C, the time is 2h, the vacuum sublimation drying temperature is -25°C, the vacuum degree is -0.085MPa, and dried for 5h Finally, 11.4 kg of freeze-dried fennel lumps were obtained, which were taken out, bagged and sealed, and stored in a 4°C freezer for subsequent use;

[0062] c. Fragrance extraction: Weigh 2 kg of freeze-dried fennel lumps and extract the spice components with 10 kg of dimethyl ether. The operating conditions are extraction temperature 40 ° C, extraction pressure 0.8 Mpa, extraction time 50 min; after the extraction is completed, the dimethyl ether extract After filtering to remove particulate impurities, it is pumped into the evaporation tank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com