Steel wire tensile force equalizer for lift car

A technology of tension equalizer and elevator car, which is applied in the field of elevators and can solve the problems of elevator safety, influence on operation stability, and inconsistent tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The steel wire tension equalizer for the elevator car of the present invention will be further described below in conjunction with the accompanying drawings.

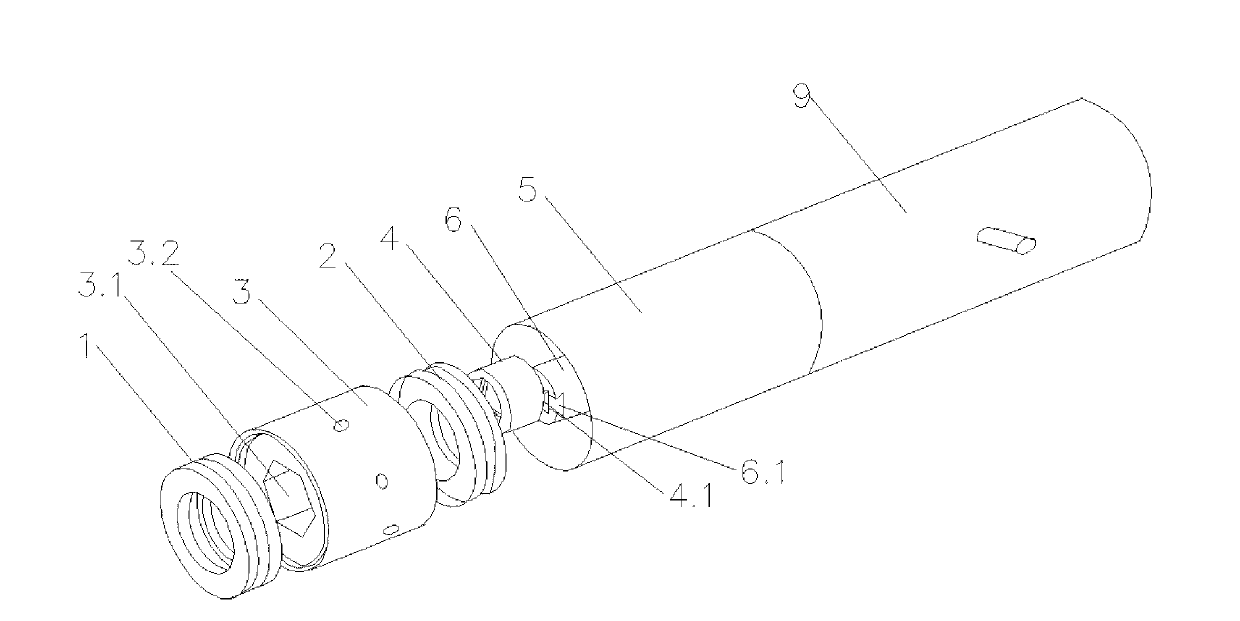

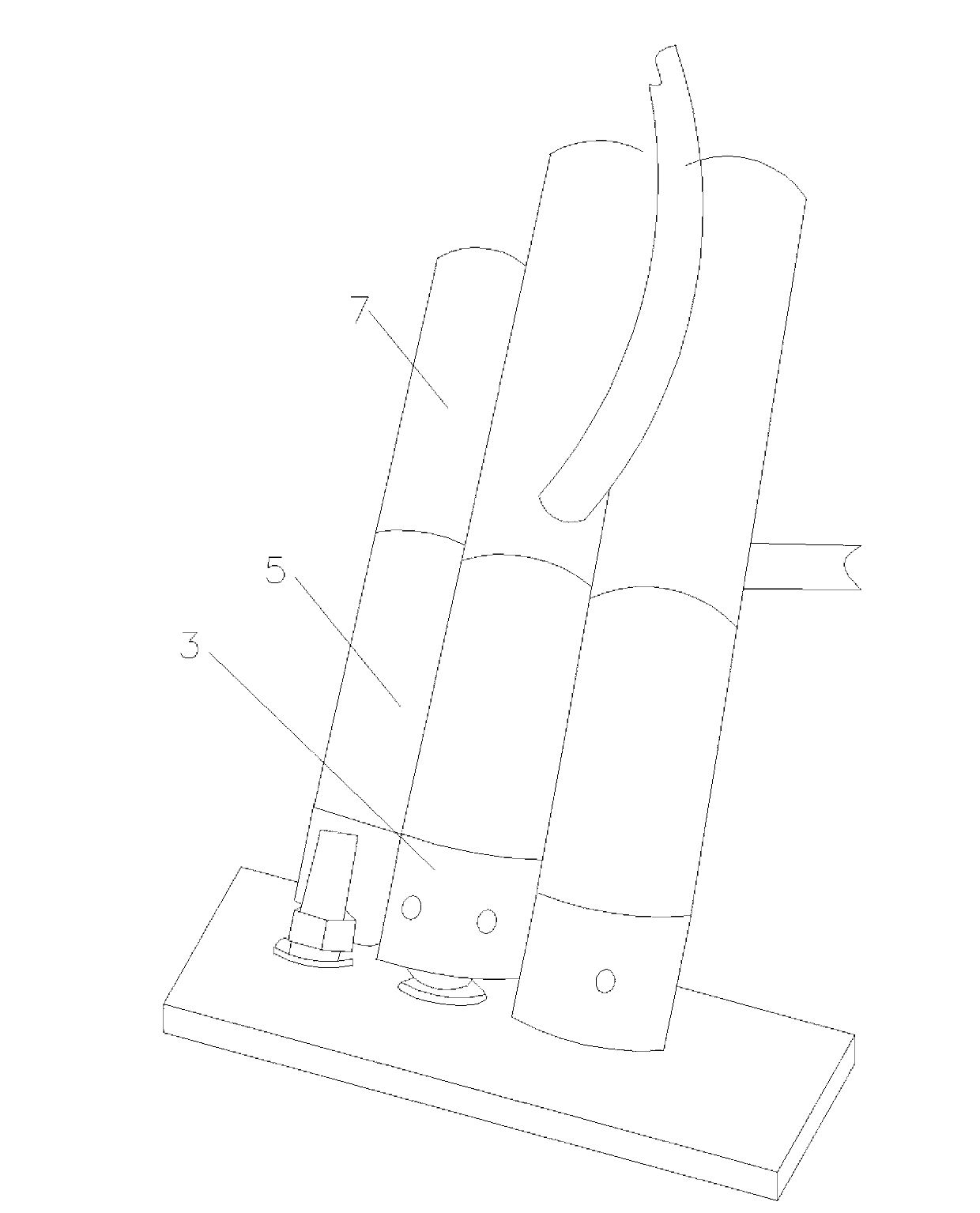

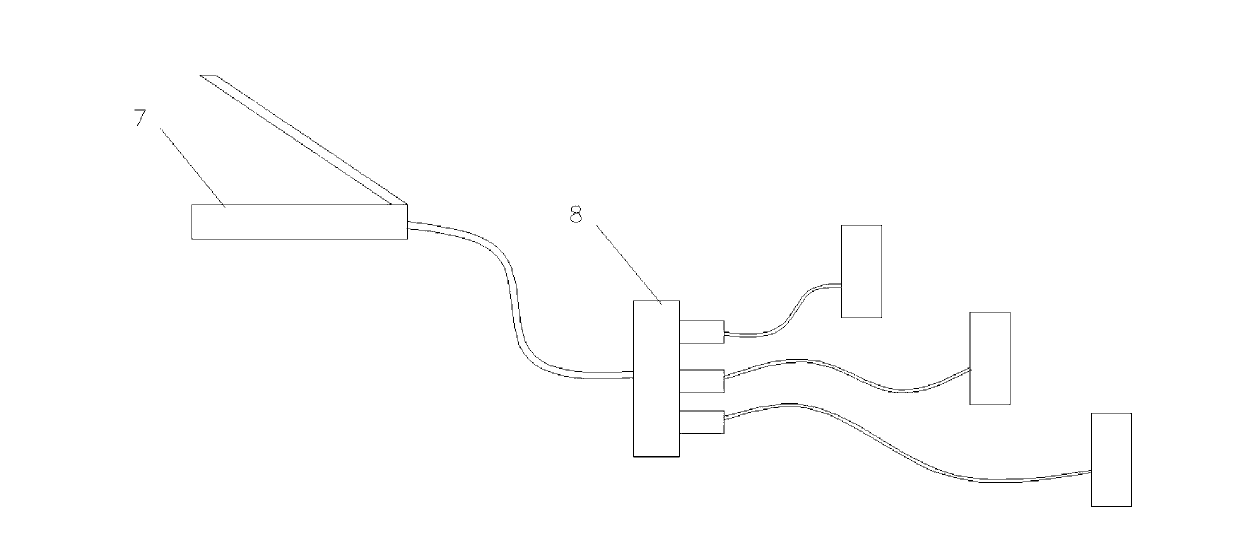

[0016] Such as figure 1 , figure 2 , image 3 As shown, the steel wire tension equalizer for the elevator car of the present invention includes multiple sets of steel wire tension equalizers capable of generating the same tension, and each set of steel wire tension equalizers includes a set of steel wire tension equalizers that are sequentially sleeved on the screw rods of the steel wires that fix the elevator car. The first one-way thrust ball bearing 1, the second one-way thrust ball bearing 2 and the nut sleeve 3, the connecting head 4 screwed together with the screw of the steel wire of the fixed elevator car, the connecting sleeve 5 and the straight line provided with the telescopic rod 6 Telescopic mechanism: the end of the telescopic rod 6 is connected to the connector 4, the telescopic rod 6 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com