Double-pipeline concentrated phase delivery system parallel discharge and blockage device and automatic control method

A conveying system and conveying control technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of long conveying distance, poor material movement, pipeline leakage, etc., so as to avoid material blockage in pipelines and normal material supply Smooth, less leakage and breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

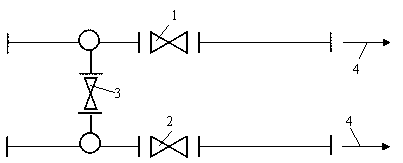

[0019] In the present invention, a parallel blockage removal device is provided in the dual-pipeline dense-phase conveyance control system, and the parallel blockage removal device is an electronically controlled pneumatic valve 3 installed on each parallel conveyance pipeline to the silo of the double-pipeline dense-phase conveyance control system. And use the electro-pneumatic valve 3 to connect the parallel pipeline, such as figure 1 , figure 2 As shown (the diameter of the control valve 1, 2 and the electro-pneumatic valve 3 is the same as the inner diameter of the dense phase pipe). Connect the electro-pneumatic valve 3 with the PLC control system 20, and control the electro-pneumatic valve through the PLC control system, such as image 3 shown.

[0020] Install a pressure transmitter on the delivery pipeline to detect the pressure change of the delivery pipeline, use the industrial computer 21 as the management level of the system to complete the collection, processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com