Indexable drilling bore chamfer compound cutter

A compound cutting tool and chamfering technology, applied in drilling tool accessories, drilling, manufacturing tools, etc., can solve the problems of not further improving processing efficiency, unable to ensure the stability of processing quality, increasing tool debugging time, etc., to reduce auxiliary processes. , Improve processing efficiency and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

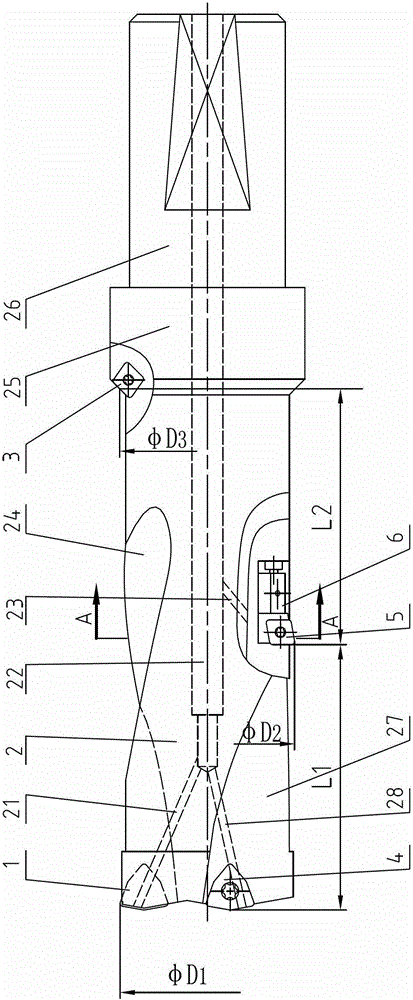

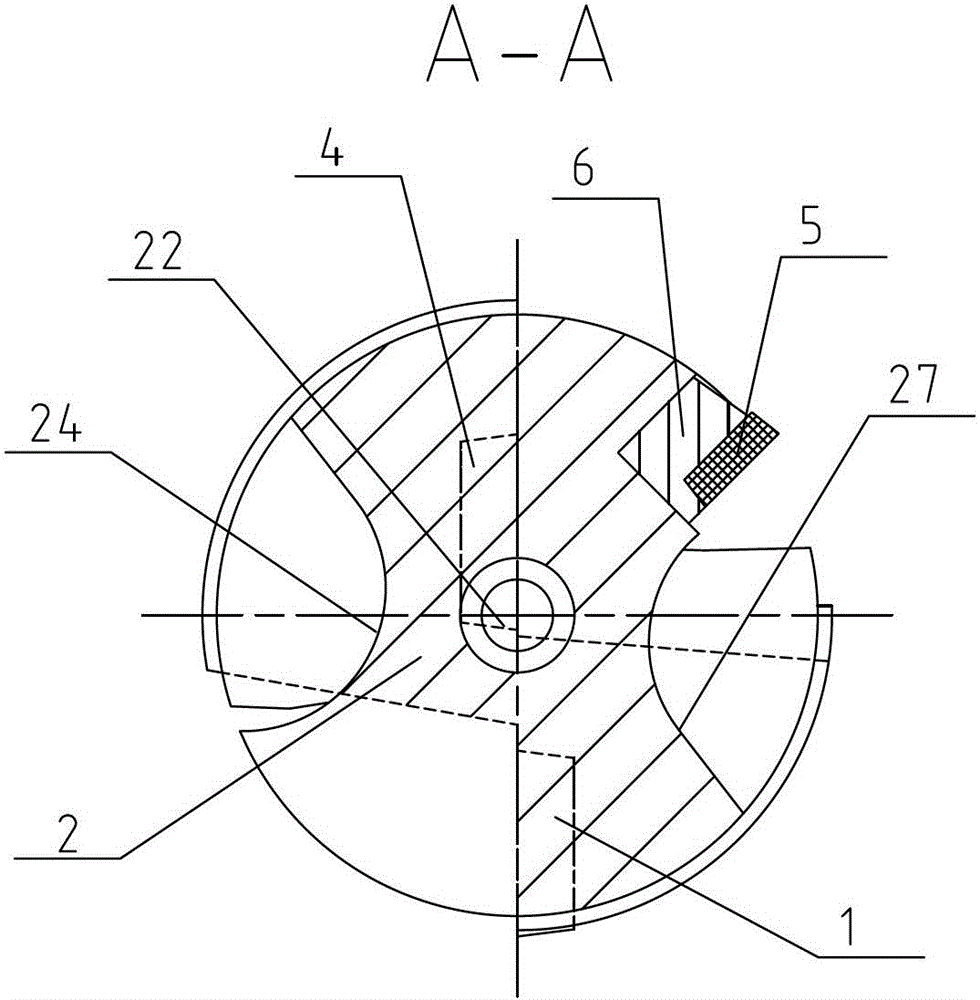

[0011] See figure 1 , 2 As shown, the indexable drilling, boring and chamfering compound tool of the present invention includes a cutter bar 2, an inner blade blade 4 and an outer blade blade 1, and the cutter rod 2 is located at the rear part of the shaft shoulder 25 and is provided with a handle 26 connected to the tool seat, The front portion is provided with an inner edge chip removal groove 27 and an outer edge chip removal groove 24, and the inner edge blade 4 is installed at the front portion of the inner edge chip removal groove 27, and the outer edge blade 1 is installed at the outer edge chip removal groove 24 front. The blade 1 controls the diameter φD1 of the drilled hole. The inner blade blade 4 and the outer blade blade 1 of the present invention are both indexable hard alloy shallow hole drilling blades, and an 80° indexable hard alloy shallow hole drilling blade can be used. The inner end of the blade blade 4 exceeds the central axis of the cutter bar 2 by 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com