Guide vane assembly for continuous flow machines

A technology of guide vanes and flow machinery, applied in the direction of engine components, mechanical equipment, engine functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

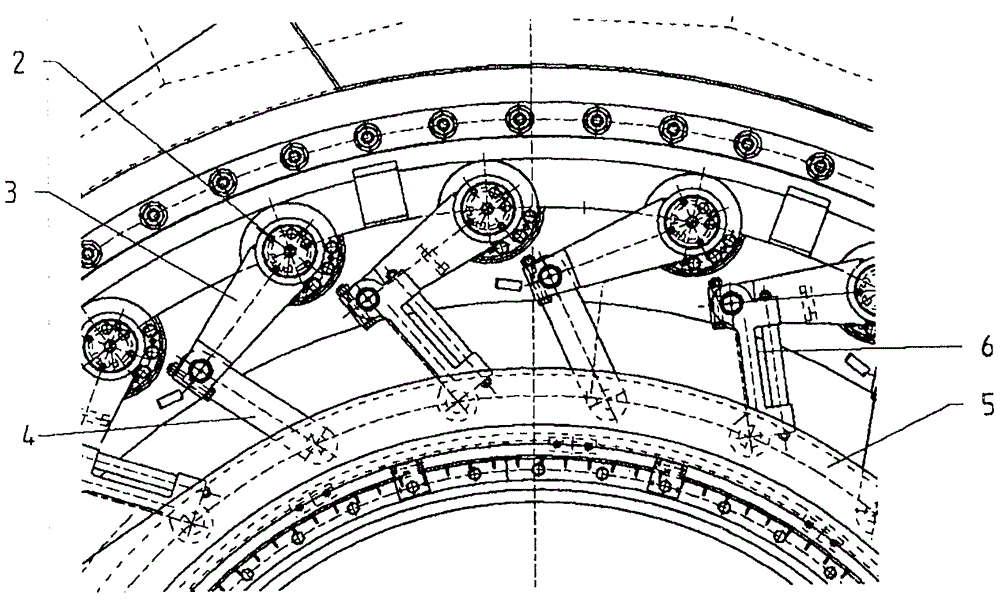

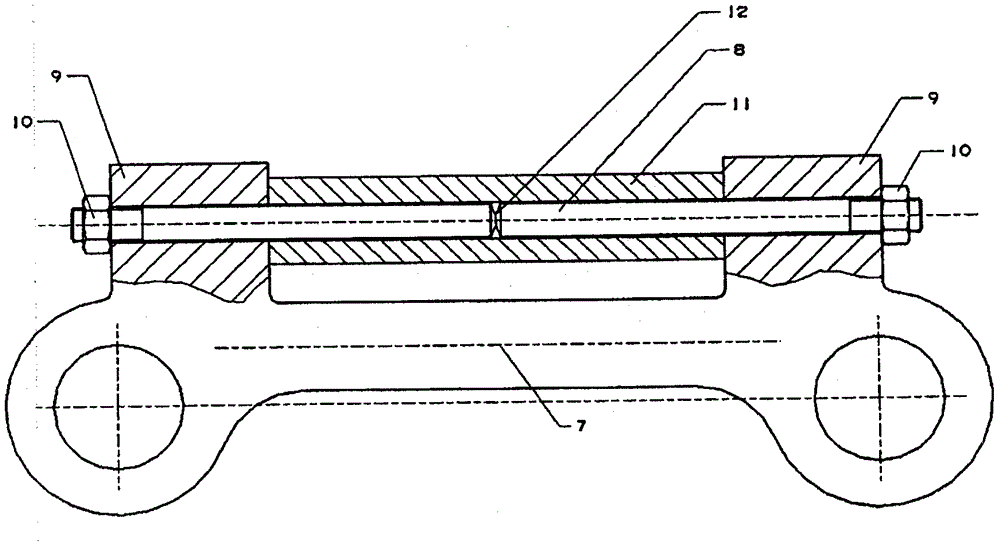

[0007] Now, the present invention will be described based on the example shown in the accompanying drawings, in which, figure 1 Showing a guide vane assembly for a Francis turbine with a bent fractured connecting rod according to the invention, figure 2 A detailed demonstration of a bending fracture link according to the present invention is provided.

[0008] figure 1 A cross-section of a guide vane assembly of a Francis turbine is shown. The shaft 2 of the guide vane can be seen in the figure, which shaft 2 is fixed via a guide vane rod 3 and a connecting rod 4 via a hinged connection to the adjusting ring or rod on the adjusting ring 5 . Thus, by turning the adjusting ring 5 , all the guide vanes can be adjusted uniformly via the guide vane shaft 2 . In an end position, the guide vanes also serve as shut-off valves. Since foreign matter can enter the turbine and the guide vane assembly in the water flow, there is a risk that foreign matter becomes trapped by the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com