Microemulsion method for preparing nanometer cathode Ln2NiO4 of solid oxide fuel cell

A solid oxide and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor chemical stability and high polarization resistance, and achieve simple and easy preparation methods, good chemical compatibility and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

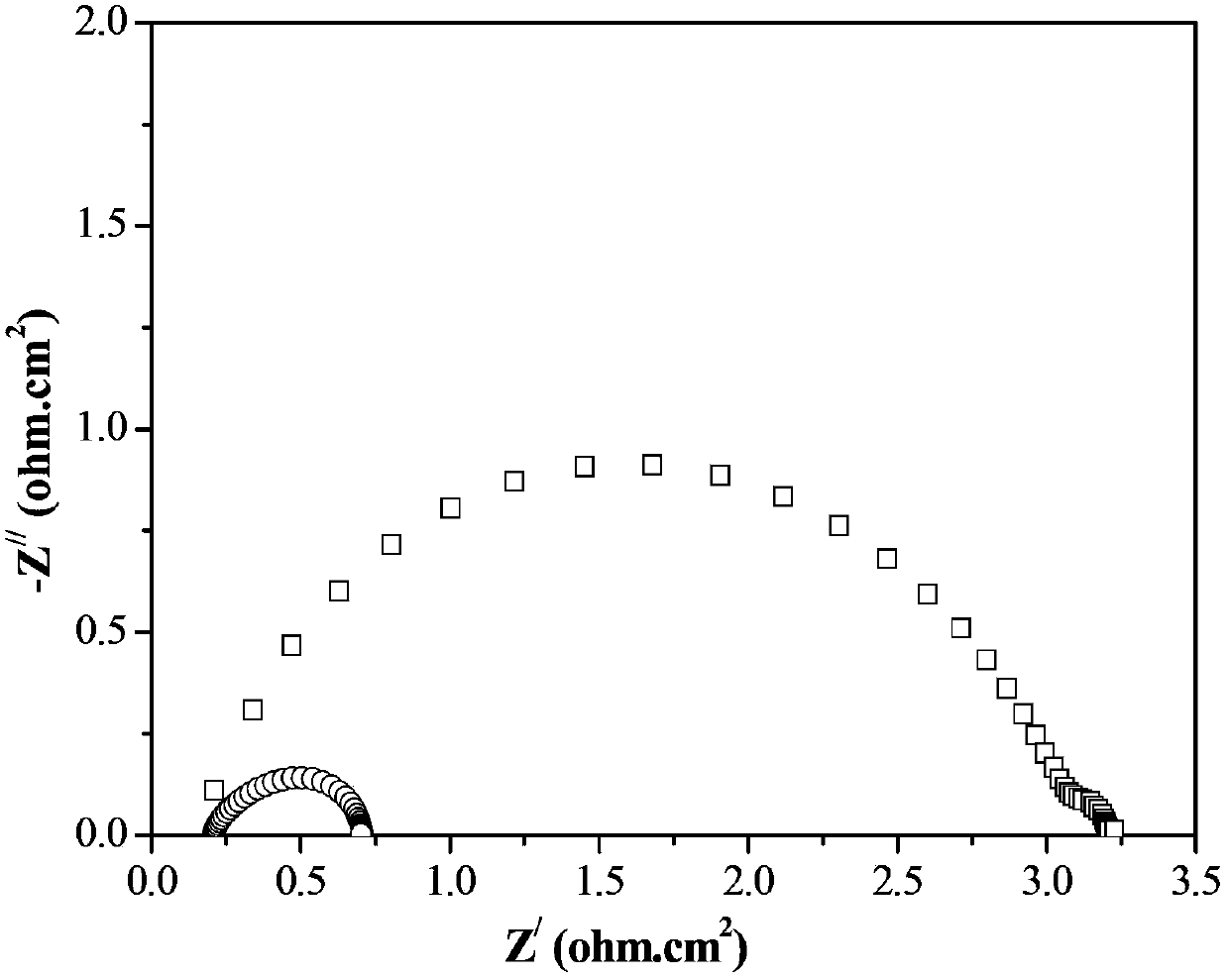

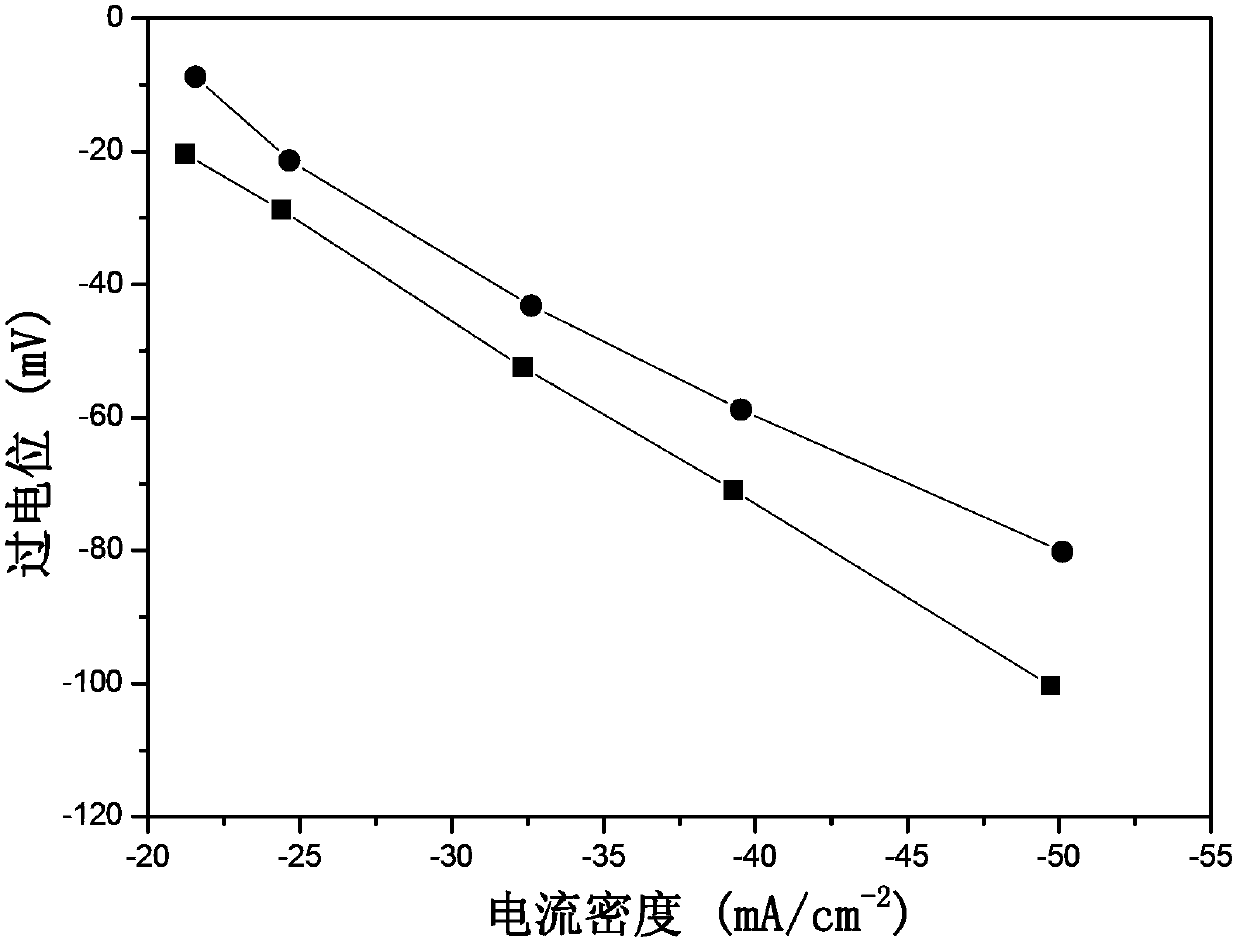

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment 1: In this embodiment, the microemulsion method is used to prepare the nanoscale cathode Ln for solid oxide fuel cells 2 NiO 4 The method is implemented in the following steps:

[0018] 1. Mix 5-20mL oil phase, 2-8g surfactant and 0.5-3mL co-surfactant, stir evenly and divide into solution A and solution B;

[0019] 2. Dissolve 1.0-8.0g of soluble rare earth nitrate and 0.5-2.5g of nickel nitrate in 10-100mL of deionized water, stir well and add to solution A to obtain microemulsion A;

[0020] 3. Dissolve KOH or NaOH in deionized water to form a strong alkali solution with a concentration of 0.5-1.0 mol / L, and then add it to solution B to obtain microemulsion B;

[0021] 4. Mix microemulsion A and microemulsion B under stirring conditions, control the temperature of the mixed solution at 20-40°C, stir and react for 2-6 hours, then let stand for 1-5 hours, then centrifuge and wash to obtain Solid phase, the solid phase is sintered at a rate of 5-1...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 mixes 5 mL of cyclohexane, 5 g of sodium dodecylbenzenesulfonate and 3 mL of isoamyl alcohol. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that step 3 dissolves 1 g of KOH in 20 mL of deionized water. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com