Bridging and wire-leading sensor of monolayer multi-point touch screen and forming process thereof

A bridging wire, single-layer multi-point technology, which is applied in the field of single-layer multi-touch screen sensors and its molding process, can solve the problems of low yield rate and high difficulty of alignment and binding between sensors and FPC, and achieve high yield rate, Guaranteed width and line spacing, reduced area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

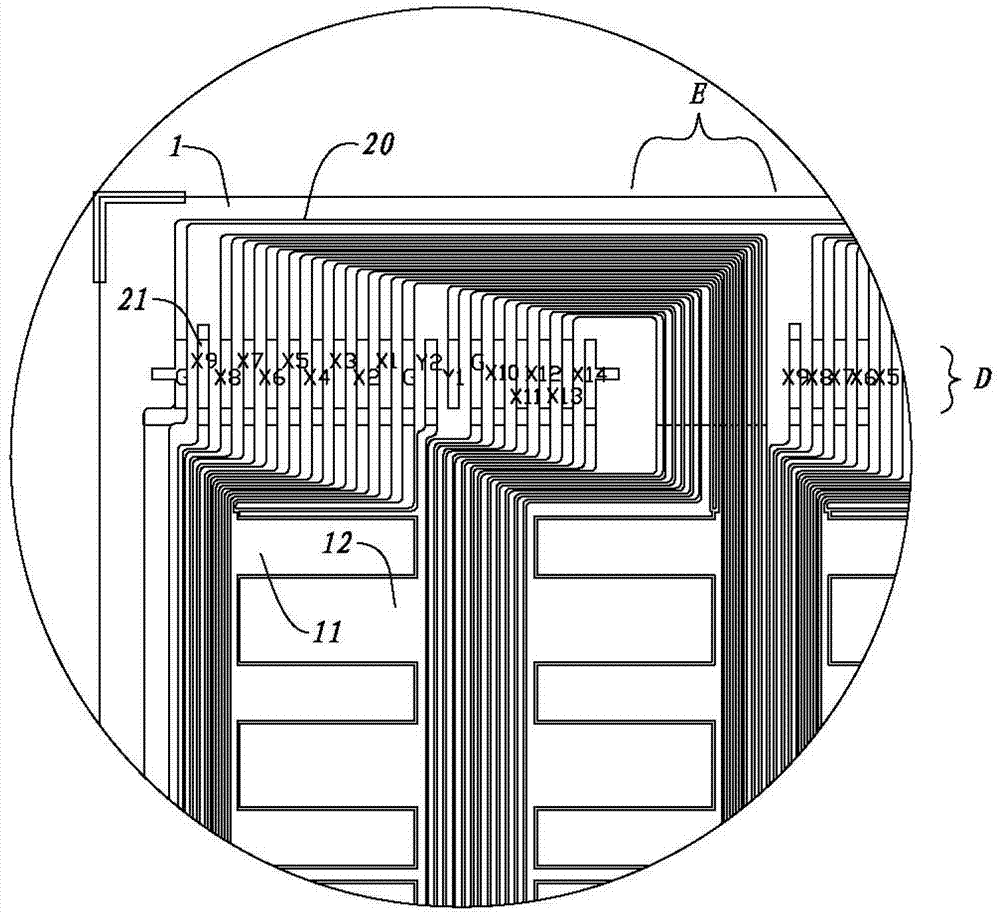

[0038] Such as figure 1 As shown, the schematic diagram of the sensor according to Embodiment 1 of the present invention includes the pattern of the ITO sensing electrode, the distribution schematic diagram of the lead wire 20 and the contact point 21 .

[0039] The sensor structure of the present embodiment is as follows:

[0040] An insulating and transparent substrate 1, which is a thin film of PET material (ITO FILM), is distributed with ITO sensing electrodes on one side of the substrate 1, and the sensing electrodes have electrode patterns that can sense multi-point human touch; the scheme of this electrode pattern Many, the present embodiment uses the shape of the planar comb, the teeth of the comb are rectangular, including the X electrode 11 and the Y electrode 12, wherein, the Y electrode 12 extends vertically along the substrate 1, but the X electrode 11 extends along the The extension direction of the Y electrodes 12 is distributed, and the comb-shaped matching pa...

Embodiment 2

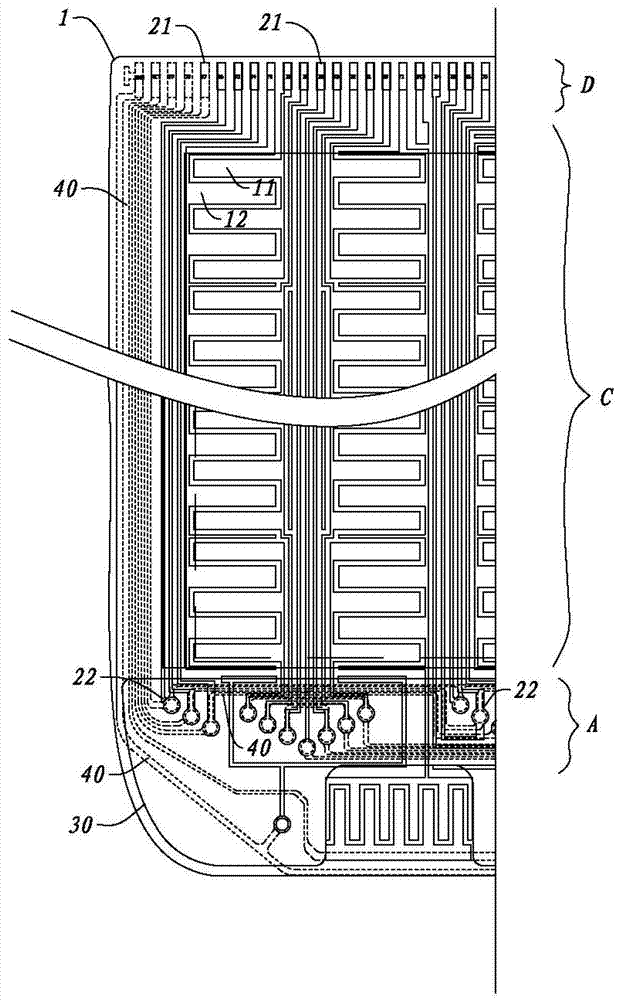

[0052] Such as figure 2 Shown is a schematic diagram of Embodiment 2 of the present invention.

[0053] Compared with the previous embodiment, the biggest difference is that the insulating layer 30 is divided into two independent regions A and B along with the bridging layer. Therefore, part of the bridging point 22 is located in the area B on one side where the contact 21 is located, and the other part is located in the area A on the other side opposite to the contact 21 on the periphery of the area where the sensing electrode is located. For the X electrode 11 on the side close to the contact 21 in the B area, part of the extended lead wire 20 is connected to the contact 21, and the end of the other part is a bridging point 22; the rest (A area) of the X electrode 11, its end is a bridging point point 22;

[0054] This form, which can be called "up and down bridging" form, has two bridging areas A and B, which is characterized by greatly reducing the single-layer distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com