Full-automatic control system and control method of ultra pure water machine

An ultra-pure water machine, ultra-pure water technology, applied in the control/regulation system, comprehensive factory control, comprehensive factory control and other directions, can solve the problem of lack of accurate and detailed flow monitoring and alarm function, affecting the quality of ultra-pure water and reducing the service life of the system And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0228] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

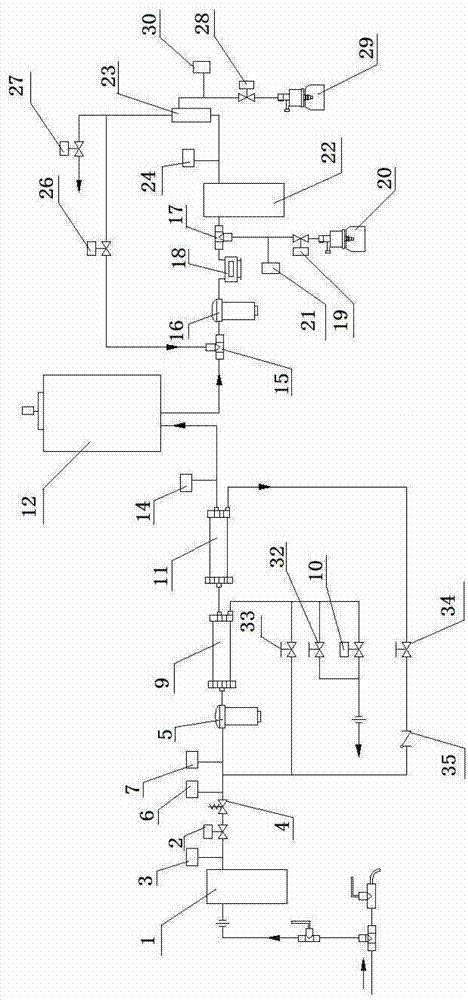

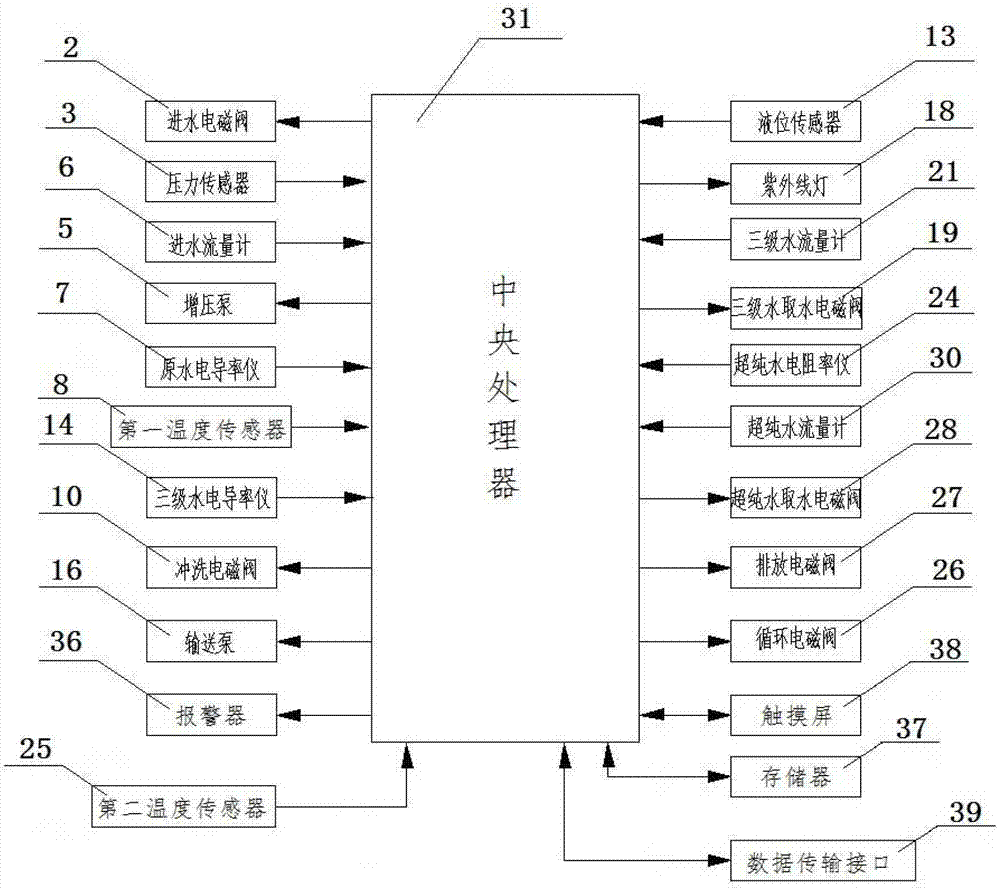

[0229] like figure 1 , figure 2 As shown, an ultrapure water circulation control system includes a raw water filter element 1 connected to a water inlet pipe, a central processing unit 31, an alarm 36, a memory 37 and a touch screen 38, and the water outlet of the raw water filter element 1 is connected to a water inlet solenoid valve 2, a pressure sensor 3 is installed in the water pipe between the water outlet of the raw water filter element 1 and the water inlet of the water inlet solenoid valve 2, and the water outlet of the water inlet solenoid valve 2 is connected to the booster pump through a pressure reducing valve 4 5, the water pipe between the pressure reducing valve 4 and the booster pump 5 is provided with a water inlet flowmeter 6 and a raw water conductivity meter 7, and the raw water conductivity meter 7 is built with a first temperature sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com