Method for measuring roll angle of guided cartridge based on scanning laser beams

A roll angle measurement and scanning laser technology, applied in the direction of measurement device, measurement angle, surveying and navigation, etc., can solve the problems of easy interference of geomagnetism, high cost of use, and inability to initially align the roll attitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described in detail below with reference to the accompanying drawings and examples.

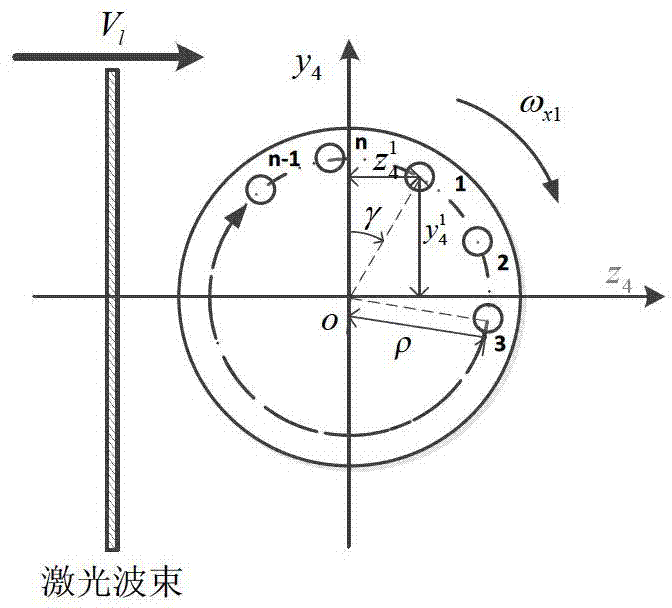

[0081] The roll angle measurement system of the guided projectile based on the scanning laser beam proposed by the invention is suitable for the roll angle measurement of the projectile guided ammunition. The following takes a guided projectile as an example to illustrate the specific calculation steps.

[0082] The speed of the guided projectile is 800m / s, the rotational speed is 5 revolutions / s, and the distance from the laser scanning station is 400m.

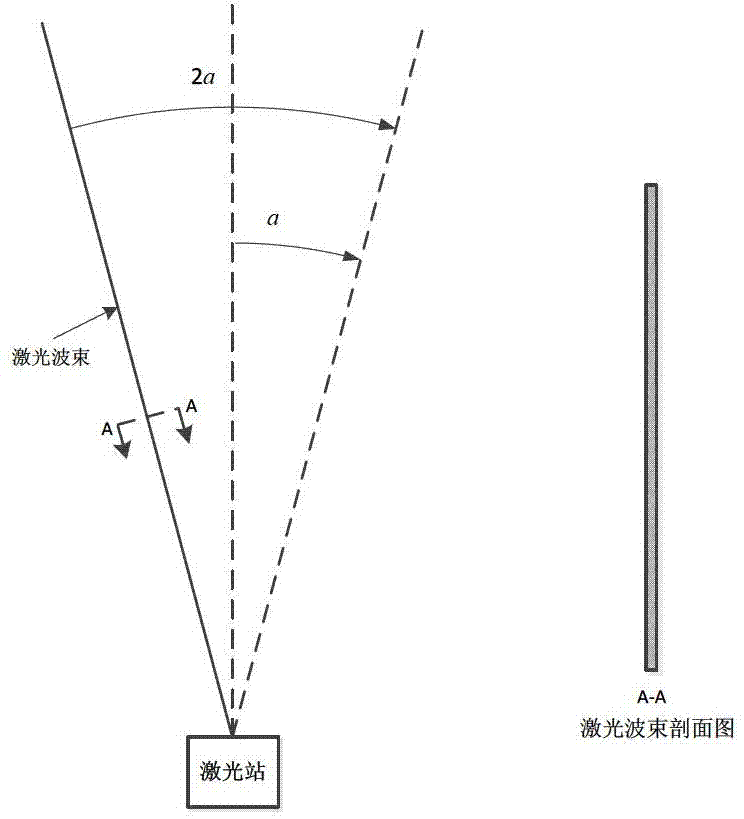

[0083] The specific parameter selection of the laser scanning beam: the scanning range is ±a=±5°, and the scanning frequency is f 0 =40Hz, the maximum operating distance is R=3Km.

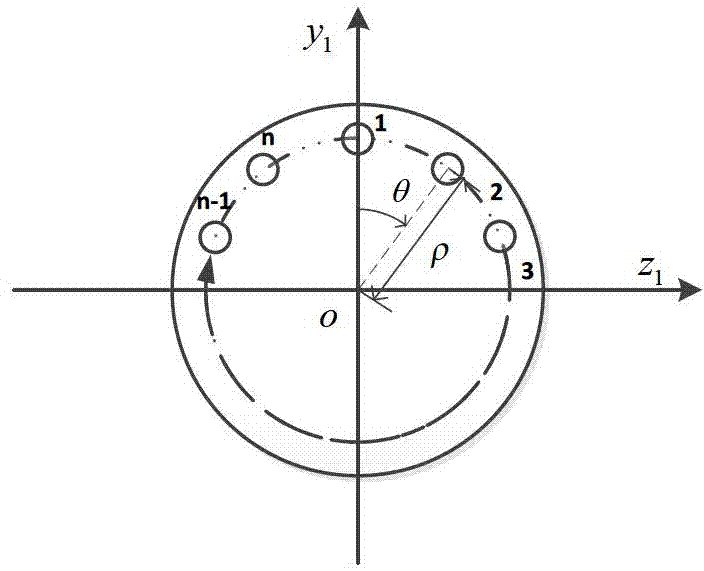

[0084] Specific parameters of the laser receiver: laser receiver n=8, interval angle θ=45°, installation circle radius ρ=0.05m, such as Figure 4 shown.

[0085] (1) Let the time when the first laser receiver receives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com