Three-dimensional hole shape detection method and system based on optical coherence tomography

A technology of optical coherence tomography and detection method, which is applied in the field of three-dimensional hole shape detection based on optical coherence tomography scanning, and can solve the problems of limited scanning range of optical coherence tomography and inability to scan imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

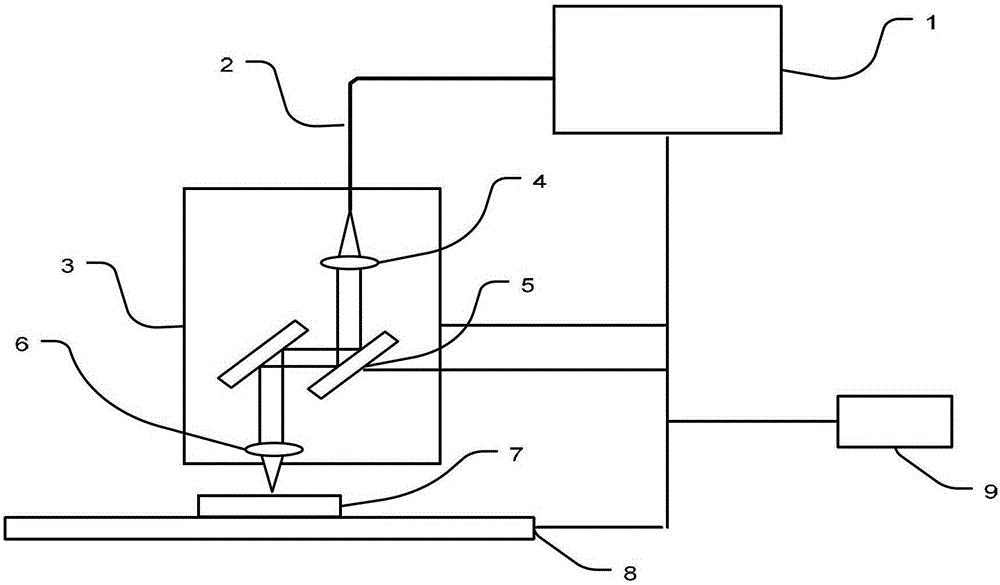

[0026] A three-dimensional hole shape detection system based on optical coherence tomography, such as figure 1 As shown, it is mainly composed of an optical coherence tomography device 1 , a system fiber collimator 4 , a two-dimensional scanning galvanometer 5 , a scanning objective lens 6 , a vertical translation platform 3 , a translation platform 8 and a computer 9 . Both the longitudinal movement platform 3 and the translation platform 8 are connected with the computer 9, and the computer 9 controls the movement of the longitudinal movement platform 3 and the translation platform 8. The system fiber collimator 4 , the two-dimensional scanning galvanometer 5 , and the scanning objective lens 6 are fixed on the longitudinal movement platform 3 and follow the movement of the longitudinal movement platform 3 . The circuit board 7 to be tested is placed on the translation platform 8 and moves along with the translation platform 8 . The longitudinal movement platform 3 is verti...

Embodiment 2

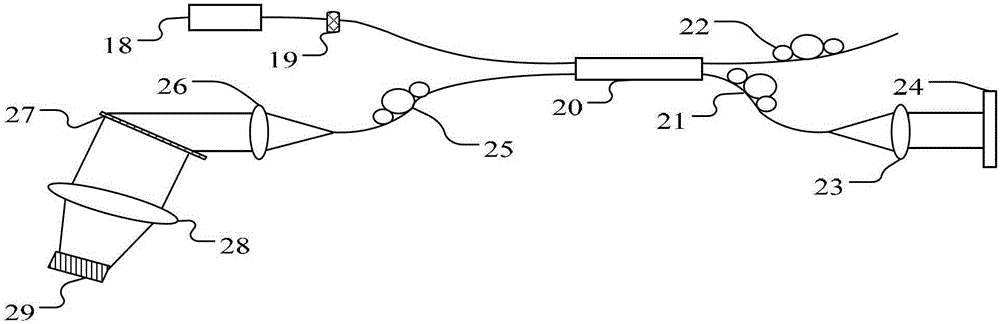

[0046] The system configuration and detection method of embodiment 2 are basically the same as those of embodiment 1, the difference is that in the three-dimensional hole shape detection system based on optical coherence tomography, the optical coherence tomography device 1 used is changed to a spectral domain optical coherence layer Analytical imaging device, see image 3 . At this time, the optical coherence tomography device 1 is mainly composed of a broadband continuous light source 18, an optical isolator 19, a spectral domain fiber coupler 20, 3 polarization controllers 21, 22, 25, 2 fiber collimators 23, 26, Mirror 24, grating 27, spectral objective lens 28 and line scan camera 29 are composed. The broadband continuous light source 18 emits a broadband spectrum, enters the spectrum domain fiber coupler 20 through the optical isolator 19, and is divided into two beams by the spectrum domain fiber coupler 20, one of which passes through the first polarization controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com