Pillar robbing method of reconstructed artificial stud

A technology of artificial pillars and ore pillars, which is applied in the mining of ore pillar resources and the mining of ore pillars. It can solve the problems of difficulty in ensuring the role of the support control stope roof, high mining costs, and difficulty in determining the thickness of the mine wall. The cost is economical and feasible, and the effect of safe and economic recovery is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

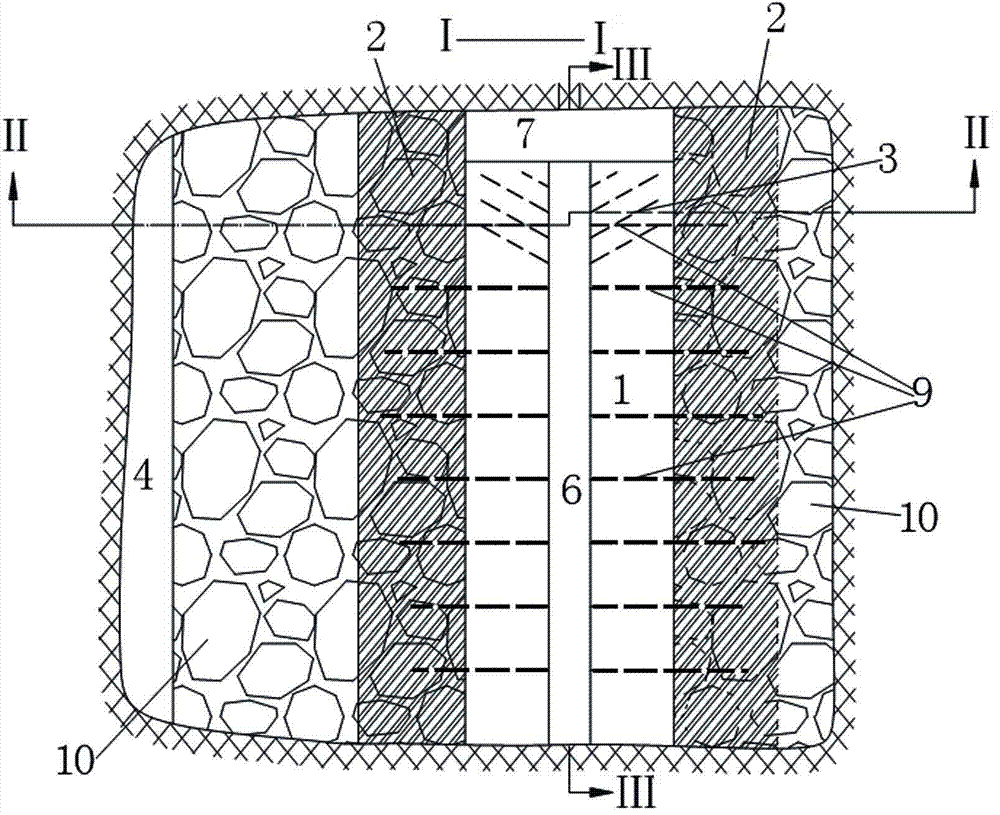

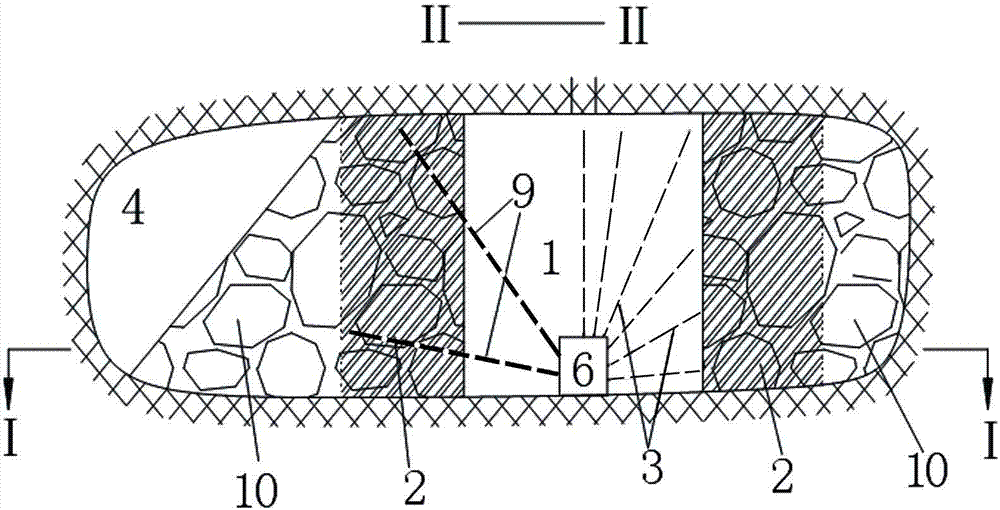

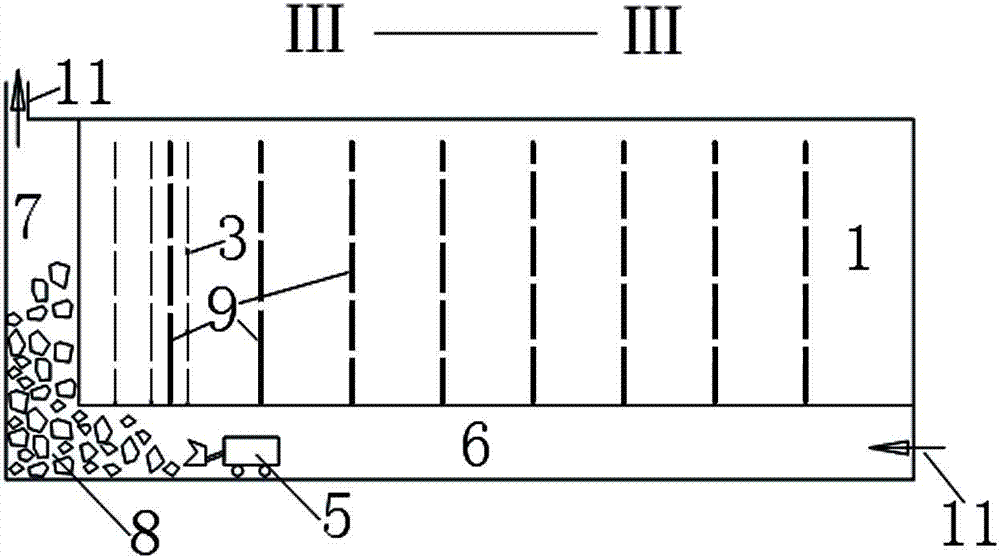

[0017] Due to the influence of mining disturbance during the primary mining of the ore body, the engineering geological conditions of the secondary mining pillar resources in metal mines are quite complicated: 1. The redistributed in-situ stress field often produces stress concentration in key parts such as the pillar; 2. The empty field method The mining goaf has not been treated for a long time, and the roof often falls or becomes unstable. Generally, there are no conditions for personnel and equipment to work safely in the goaf; 3. Some waste rocks fill the mining goaf or empty field The mined-out area to be filled later is not self-supporting because the filling body is a loose body, so it cannot well support the roof of the goaf. For the above-mentioned engineering geological conditions, the present invention will be further described in conjunction with the accompanying drawings and specific engineering implementation methods and processes (see attached figure 1 , figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com