A kind of panel area drying method

A panel and dewatering technology, which is applied in the direction of earth drilling, mining equipment, safety devices, etc., can solve the problems of large dewatering investment, long dewatering and drainage time, unfavorable mining operations, etc., to achieve short dewatering time and promote Maximum recovery and the effect of improving the mining operation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

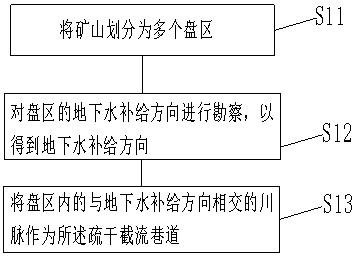

[0057] The panel drying method provided in this embodiment includes:

[0058] S11 divides the mine into multiple panels;

[0059] S12 survey the groundwater recharge direction of the panel to obtain the groundwater recharge direction;

[0060] S13 uses the veins intersecting with the groundwater supply direction in the panel as the dredging and intercepting roadway.

[0061] In this embodiment, the panel is designed with multiple piercing veins intersecting with the groundwater supply direction of the panel (the extension direction of the piercing veins and the groundwater supply direction form an acute angle or an obtuse angle, or both are perpendicular), and the panel is closest to the groundwater supply direction The piercing vein is used as the dredging and intercepting roadway, and a draining chamber and a draining borehole are set in the roadway. The extension direction of the draining borehole is opposite to or intersects with the groundwater supply direction, and the ...

Embodiment 2

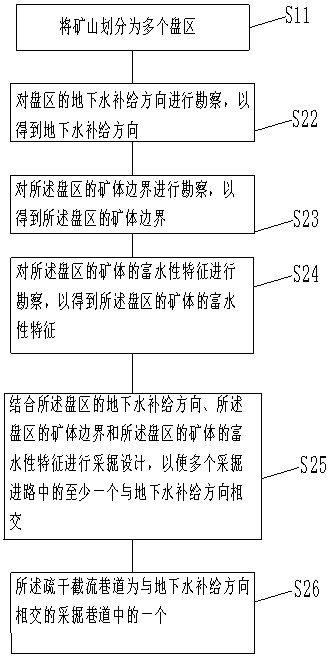

[0086] The panel drying method provided in this embodiment includes:

[0087] S21 divides the mine into multiple panels;

[0088] S22 survey the groundwater recharge direction of the panel to obtain the groundwater recharge direction;

[0089] S23 survey the ore body boundary of the panel to obtain the ore body boundary of the panel;

[0090] S24 survey the water-rich characteristics of the ore bodies in the panel to obtain the water-rich characteristics of the ore bodies in the panel;

[0091] S25 Combining the groundwater recharge direction of the panel, the ore body boundary of the panel and the water-rich characteristics of the ore body of the panel, carry out excavation design, so that at least one of the multiple mining roadways intersects the groundwater recharge direction ;

[0092] S26 Use one of the excavation roadways intersecting with the groundwater recharge direction as the drainage and interception roadway.

[0093] In this embodiment, the panel area is surv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com