External catalytic cracking heater with pre-distributed particles

An external heat extractor, catalytic cracking technology, applied in catalytic cracking, fluidized bed heat exchanger, cracking and other directions, can solve the problem of not completely solving the problem of particle erosion of heat exchange tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

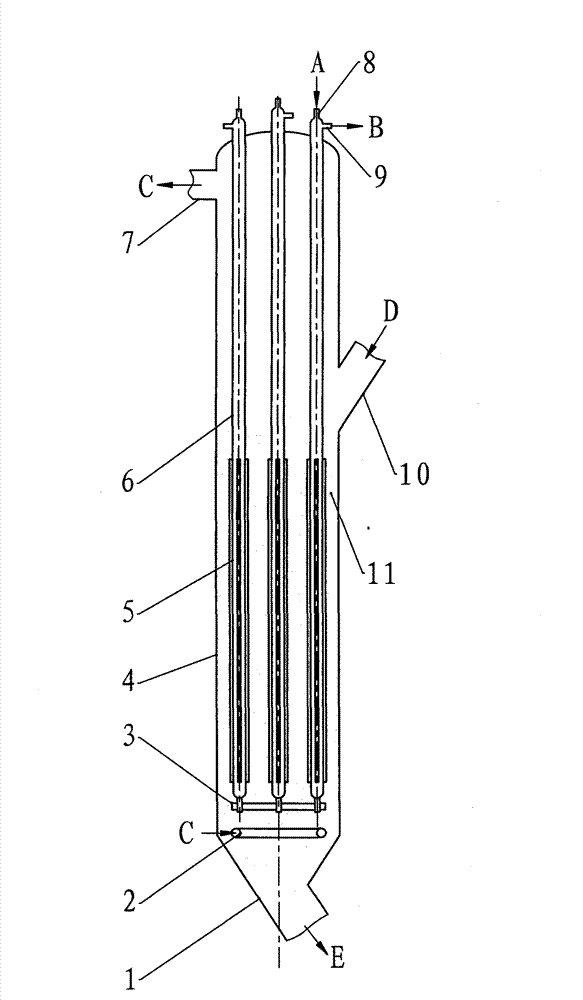

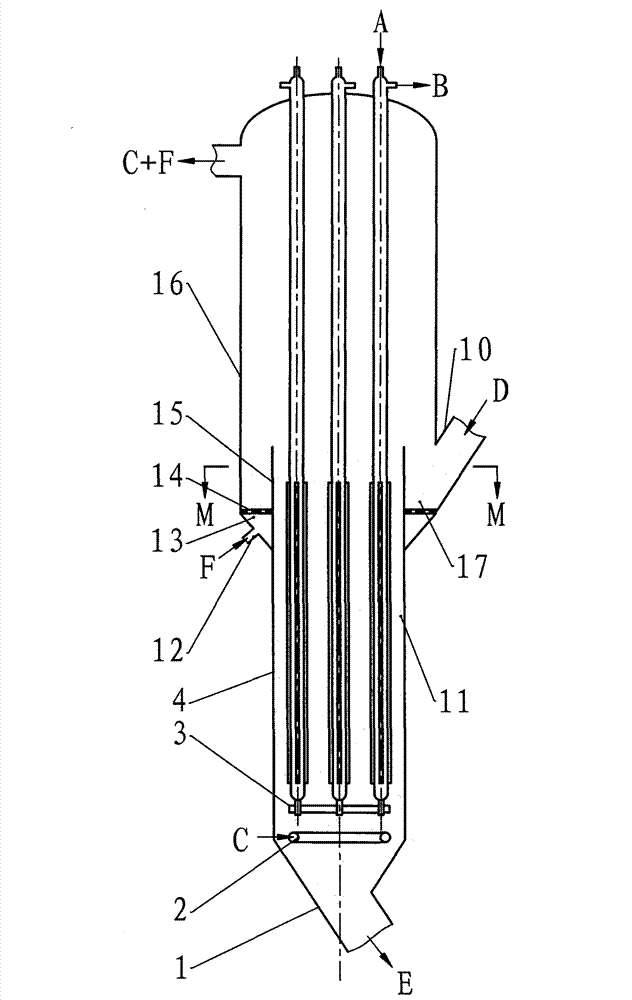

[0034] figure 2 Provide a kind of typical type of catalytic cracking external heat extractor of the present invention, it and figure 1 The difference of the common external heat extractor shown is: the hot catalyst particle D coming in from the catalyst inlet (10) in the middle part of the external heat extractor (4) first enters in an annular fluidized bed (17), and the hot catalyst particle D After entering the annular fluidized bed (17), it is rapidly dispersed on the cross section of the annular fluidized bed (17) under the action of the fluidizing wind F, and then from the inner side wall (15) of the annular fluidized bed (17). The upper edge overflows into the dense phase fluidized bed (11). The fluidizing air F first enters the fluidizing air pre-distribution cavity (13) from the gas inlet (12), and then enters the annular fluidized bed (17) through the gas distribution plate (14) arranged at the bottom. The fluidizing gas C of the dense-phase fluidized bed (11) is i...

Embodiment 2

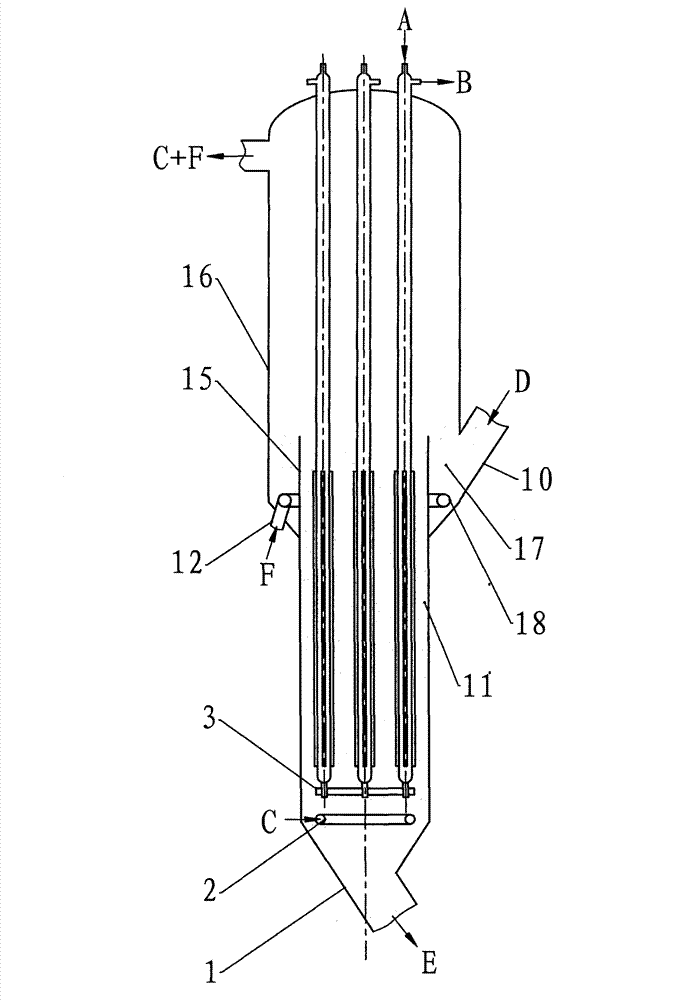

[0037] image 3 Another typical type of the catalytic cracking external heat extractor of the present invention is given. Overall, the design and figure 2 The shown external heat extractors are basically the same, except that a gas distribution pipe (18) is arranged at the bottom of the annular fluidized bed (17) instead of figure 2 Gas distribution plate (14) shown in . In contrast, the design is more figure 2 The shown scheme structure is simpler.

Embodiment 3

[0039] Figure 4 Provide another typical type of catalytic cracking external heat extractor of the present invention, this design and image 3 The shown external heat extractor is basically the same, and the difference is the design of the enlarged section (16), and figure 2 and image 3 The difference in the structure of the external heat extractor shown is that the enlarged section (16) does not extend all the way to the top of the external heat extractor (4) in this design, but only a partial section, and the diameter of the upward external heat extractor (4) It transitions to the same diameter as the dense-phase fluidized bed (11), and this structure is more suitable for the transformation of existing external heat extractors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com