Novel biological inhibitor for inhibiting activity of sulfate reducing bacteria in oil well and use method thereof

A technology of biological inhibitors and bacterial activity, which is applied in the direction of earthwork drilling and production, wellbore/well parts, etc., can solve the problems of pipe wall corrosion, accelerate oil wells, etc., and achieve the effect of improving removal rate and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 (indoor corrosion evaluation test)

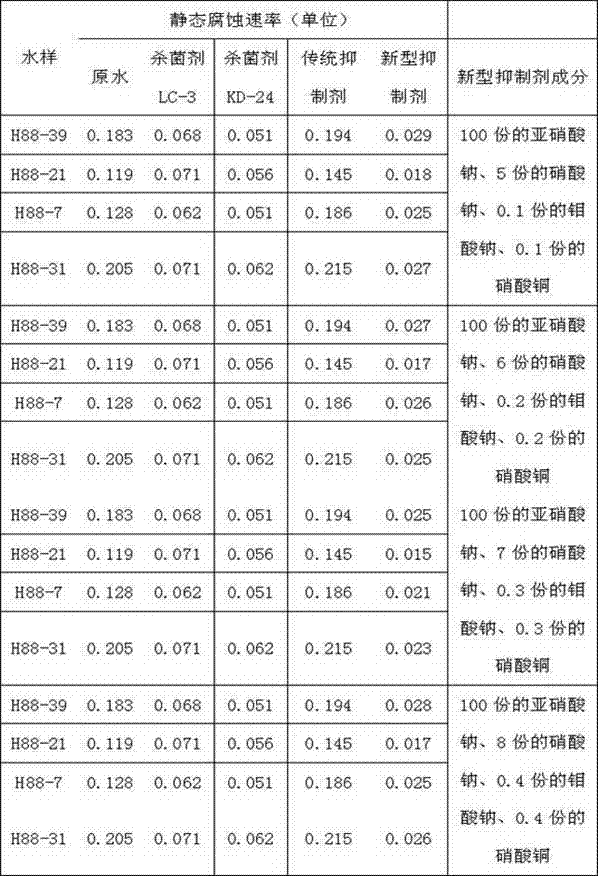

[0014] In this test, the new inhibitor used is composed of 100 parts of sodium nitrite, 5-10 parts of sodium nitrate, 0.1-0.5 parts of sodium molybdate, and 0.1-0.5 parts of copper nitrate according to the ratio of parts by mass; The agent consists of 100 parts of sodium nitrate, 5-10 parts of sodium nitrite, 0.1-0.5 parts of sodium molybdate, and 0.1-0.5 parts of copper nitrate; and 100 mg / L of fungicide LC is added to each liter of oilfield produced water -3. Bactericide KD-24, traditional inhibitors and new inhibitors were placed in 250mL anaerobic bottles at 65°C for 14 days, and the measured static corrosion rates were shown in Table 1; among them, bactericide LC-3 and bactericide KD -24 is a fungicide commonly used in oil wells in Jiangsu Oilfield; H88-39, H88-21, H88-7 and H88-31 are water samples produced by 4 oil wells in Block Huang 88 of the No. 2 Trial Production Plant of Jiangsu Oilfield. Comparing the experim...

Embodiment 2

[0017] Example 2 (indoor suppression of SRB effect)

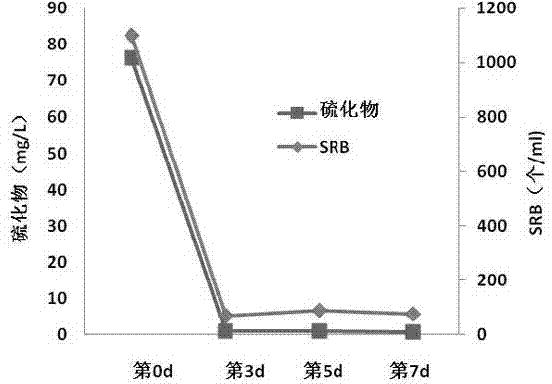

[0018] In this embodiment, the novel inhibitor used consists of 100 parts by mass of sodium nitrite, 5-10 parts of sodium nitrate, 0.1-0.5 parts of sodium molybdate, and 0.1-0.5 parts of copper nitrate. Add 100mg / L of the new inhibitor to each liter of oil well produced water, and culture it statically at 65°C, measure the amount of SRB and sulfide content in oil well produced water in different time periods, as shown figure 1 shown. The oil well produced water comes from Well Huang 88-39 in Block Huang 88 of the Second Factory of Jiangsu Oilfield. Depend on figure 1 It can be seen that the new inhibitor can effectively inhibit the activity of SRB, and the removal rate of sulfide can reach more than 98%. The sodium molybdate and copper nitrate in the inhibitor can promote the rapid growth of endogenous denitrifying bacteria to a certain extent. It shows that the inhibitor has good performance of inhibiting SRB and elimin...

Embodiment 3

[0019] Embodiment 3 (on-site application)

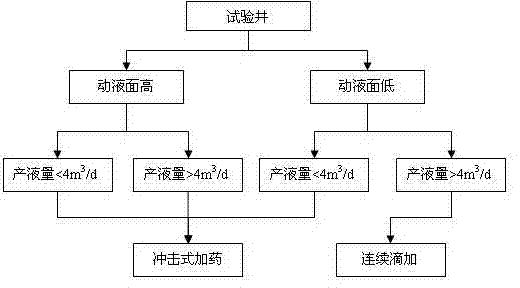

[0020] In this embodiment, the novel inhibitor used is composed of 100 parts by mass of sodium nitrite, 6-8 parts of sodium nitrate, 0.3-0.5 part of sodium molybdate, and 0.3-0.5 part of copper nitrate. Select the target well Huang 88-39 to carry out the field test. according to figure 2 Select the dosing method for the target well: continuous dripping through the casing. The casing continuous dripping method needs to be equipped with a 300L gravity automatic dripping dosing tank. According to the fluid production and water content of the oil well, the dosing cycle is 7 days, and the ratio of sodium nitrite to the total mass of sulfide in the produced water is 3:1. Calculate the dosage of sodium nitrite (the sulfide content of Well Huang 88-39 is 86.4mg / L), and add the inhibitor mother liquor. It can be seen from Table 2 that by continuously adding inhibitors, the growth of endogenous denitrifying bacteria in the oil well is stim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com