Method for preparing acetal or ketal under catalytic action of metal-organic frameworks

A metal-organic framework, catalytic preparation technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problem that catalysts cannot be recycled, product separation is difficult, and reaction conditions are harsh. problem, to achieve the effect of high conversion rate and selectivity, simple process and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

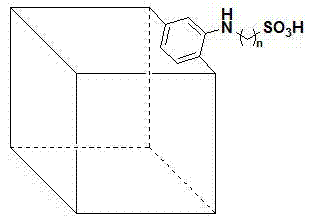

Image

Examples

Embodiment 1

[0022] Example 1: Add 10mmol of n-butyraldehyde, 10mmol of 1,3-propanediol and 20mg of IRMOF-3-1 into a 25ml one-necked bottle with a stirring bar and a reflux condenser. Vigorously stirred at 80°C for 1 hour, cooled to room temperature and filtered, the filtrate was detected by gas chromatography with a conversion rate of 98%, a selectivity of 100%, and a yield of 98%. The filter residue was vacuum dried at 120°C for 8 hours to remove water and then recycled.

Embodiment 2

[0023] Example 2: 10mmol 1-butanone, 10mmol 2,2-dimethylpropanediol and 20mg IRMOF-3-1 were respectively added to a 25ml one-necked bottle with a stirring bar and a condenser. Vigorously stirred at 90°C for 2 hours, cooled to room temperature and filtered, the filtrate was detected by gas chromatography with a conversion rate of 97%, a selectivity of 100%, and a yield of 97%. The filter residue was vacuum-dried at 120°C for 8 hours to remove water and then recycled.

Embodiment 3

[0024] Example 3: 10mmol cyclohexanone, 10mmol 2,2-dimethylpropanediol and 22mg IRMOF-3-2 were respectively added to a 25ml one-necked bottle with a stirring bar and a condenser tube. The reaction was vigorously stirred at 100°C for 2 hours, cooled to room temperature and filtered. The filtrate was detected by gas chromatography with a conversion rate of 93%, a selectivity of 100%, and a yield of 93%. The filter residue was vacuum-dried at 120°C for 8 hours to remove water and then recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com