Method for synchronous implementation of methanation of coke oven gas and in-situ purification of marsh gas

A technology of gas methane and coke oven gas, which is applied in the field of synchronous coke oven gas methanation and biogas in-situ purification, can solve the problems of incomplete utilization and high investment and operation costs, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking the anaerobic CSTR reactor for treating excess sludge in sewage plant as an example, the reactor is 100m 3 , the biogas production is 1m 3 / L / d, CH in biogas 4 The content is 60%, CO 2 The content is 40%. The composition of coke oven gas is H 2 Content 65%, CO content 5%, CH 4 Content 25%, CO 2 Content 3%. The flow rate of coke oven gas into the anaerobic reactor is 421m 3 / d, the reactor adopts mechanical stirring, and the stirring speed is 400rpm. The volume of mixed gas produced is about 200m 3 / d, the methane concentration is above 90%, and the natural gas with methane content above 98% can be obtained through further purification.

Embodiment 2

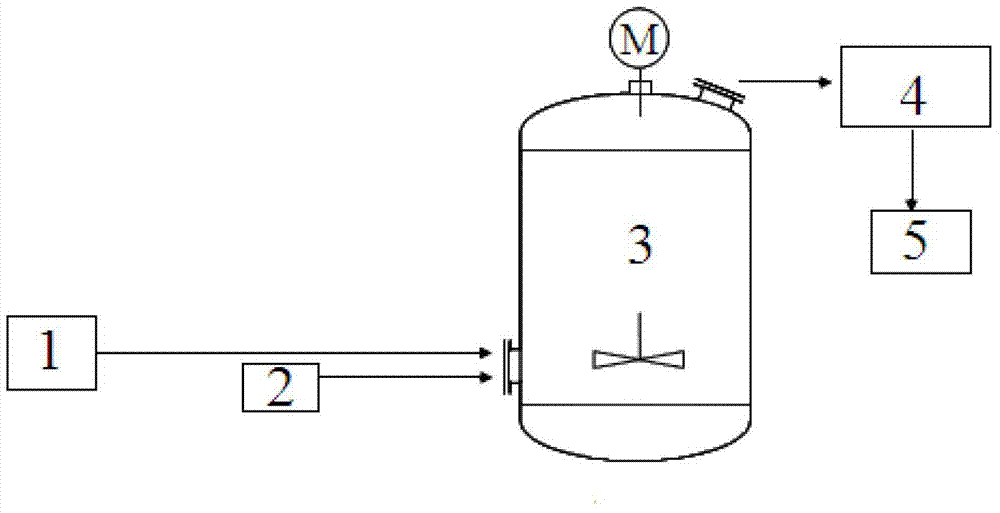

[0032] A method for synchronously realizing methanation of coke oven gas and in-situ purification of biogas, the process of which is as follows figure 1As shown, the method includes the following steps:

[0033] (a) coke oven gas 1 is passed in the anaerobic reactor 3 of processing organic waste 2;

[0034] (b) In anaerobic reactor 3, organic waste 2 is degraded by microorganisms to produce CH 4 and CO 2 , producing CO 2 Further with H in coke oven gas 1 2 combined to generate CH 4 , a small amount of CO and CO in coke oven gas 1 2 Also utilized by microorganisms with H 2 Generate CH 4 , get CH4-dominated biogas 4, where CH 4 The quality score is 91%;

[0035] (c) Separating impurities in biogas 4 mainly composed of CH4 by pressure swing adsorption to obtain natural gas 5 with high methane content (methane content above 98%).

[0036] Wherein, the flow rate of the coke oven gas 1 that passes into the anaerobic reactor 3 in the step (a) is determined by the following ...

Embodiment 3

[0041] A method for synchronously realizing methanation of coke oven gas and in-situ purification of biogas, the process of which is as follows figure 1 As shown, the method includes the following steps:

[0042] (a) coke oven gas 1 is passed in the anaerobic reactor 3 of processing organic waste 2;

[0043] (b) In anaerobic reactor 3, organic waste 2 is degraded by microorganisms to produce CH 4 and CO 2 , producing CO 2 Further with H in coke oven gas 1 2 combined to generate CH 4 , a small amount of CO and CO in coke oven gas 1 2 Also utilized by microorganisms with H 2 Generate CH 4 , get CH4-dominated biogas 4, where CH 4 The mass score is greater than 90%;

[0044] (c) Obtain natural gas 5 with high methane content (methane content above 98%) by cryogenically separating impurities in biogas 4 mainly composed of CH4.

[0045] Wherein, the flow rate of the coke oven gas 1 that passes into the anaerobic reactor 3 in the step (a) is determined by the following meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com