Constant voltage frequency ratio control system and constant voltage frequency ratio control method of multi-motor driving belt conveyor

A belt conveyor, constant voltage-frequency ratio technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as high capacitor voltage, different motor output torque, irreversible energy flow, etc., to achieve reliable Protection, smooth start, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

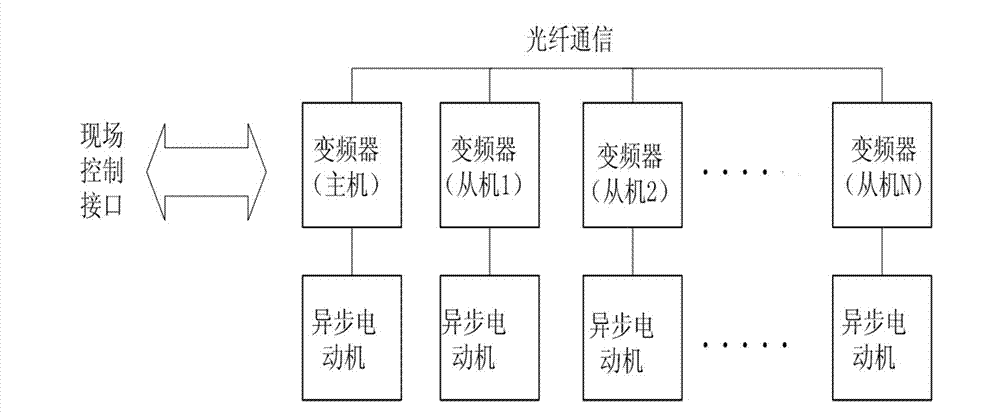

[0027] Such as image 3 As shown, the principle diagram of the constant voltage-frequency ratio control system of the multi-motor drag belt conveyor of the present invention is provided, the AC asynchronous motor shown is used to drive the operation of the belt conveyor, and the specifications of all motors are the same; each AC asynchronous motors are controlled by a frequency converter. One of all inverters is the master inverter, and the rest are slave inverters. The host inverter is used to communicate with the upper computer. The power input terminal of the frequency converter is connected to the power grid, and the power output terminal is connected to the stator input terminal of the corresponding motor; the master frequency converter communicates with all slave frequency converters through optical fiber, and the frequency converter can also det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com