Oil tank and oil pumping support for same

An oil barrel and oil pumping technology, which is applied in the direction of tanks/barrels/barrels, internal accessories, external accessories, etc., can solve the problems of inability to form a seal, low price, and unfavorable use of grease by enterprises, and achieve simple installation and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

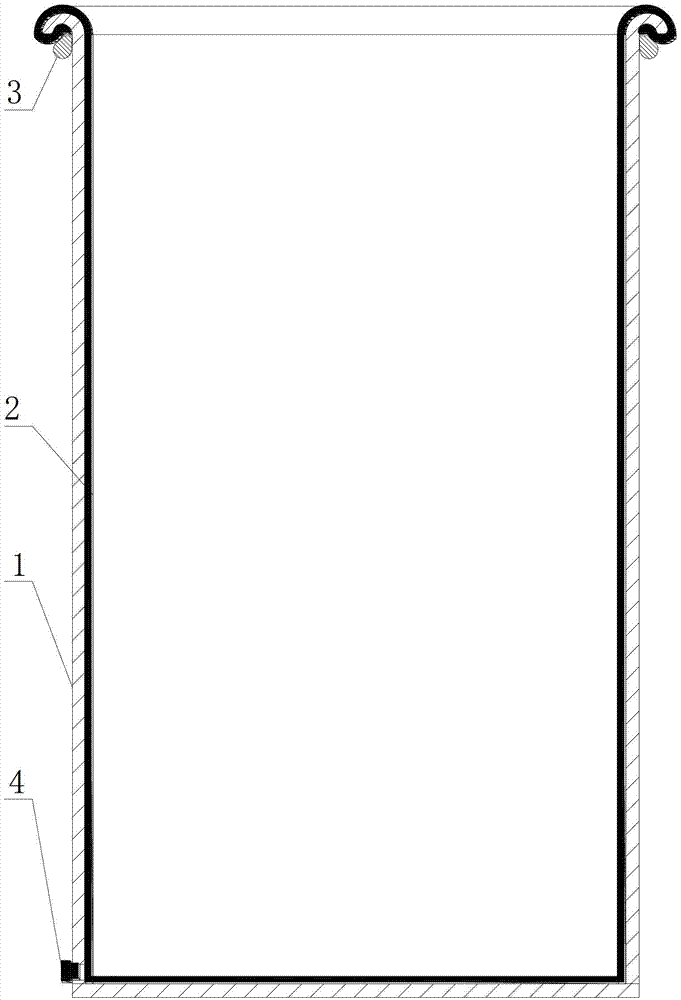

[0027] Such as figure 1 As shown, an oil barrel includes an oil barrel body 1, and the oil barrel also includes an air bag 2, the wall of the air bag 2 is attached to the inner side wall and the bottom wall of the oil barrel body 1, and the air bag 2 The sac opening is fixed on the top of the oil barrel body 1 by a fixing device, and an air hole is arranged at the bottom of the oil barrel body 1, and the air hole is sealed by an air hole plug 4.

[0028] There is an inflatable space between the wall of the air bag 2 and the inner side wall and the bottom wall of the oil drum body 1 .

[0029] Described air bag 2 is a whole, adopts flexible rubber to make.

[0030] The fixing device is a fixing ring 3, and the fixing ring fixes the bag opening of the air bag and the outlet of the oil drum body together.

[0031] The air hole plug 4 is a silk plug.

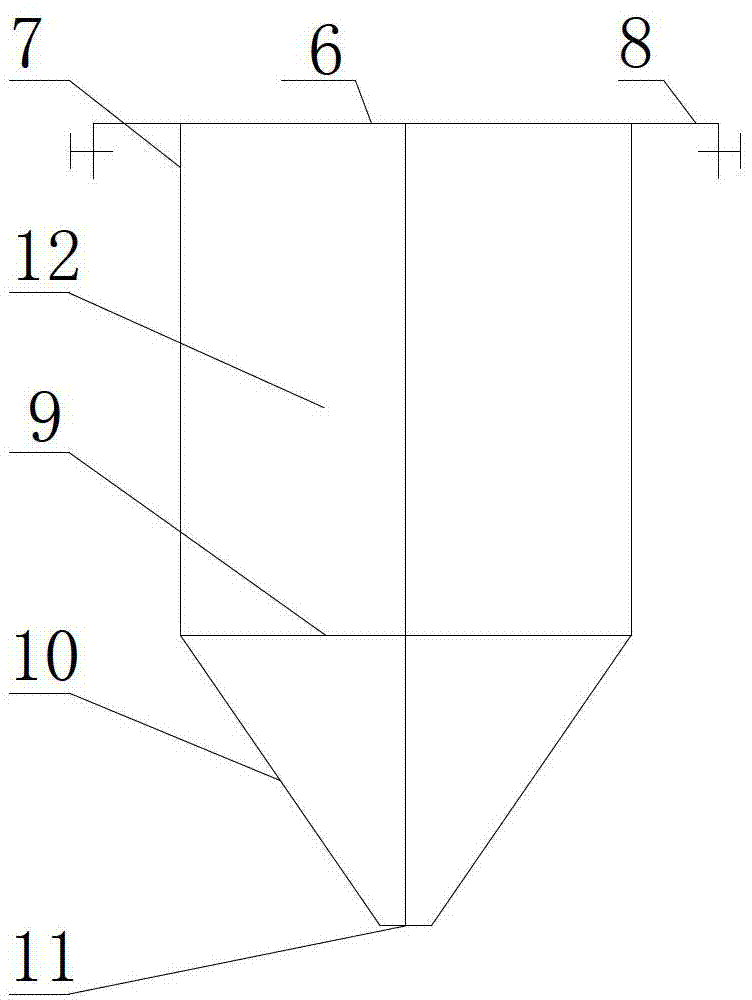

[0032] Such as image 3 with Figure 4 As shown, a kind of oil pumping support for the oil drum of the present invention, des...

Embodiment 2

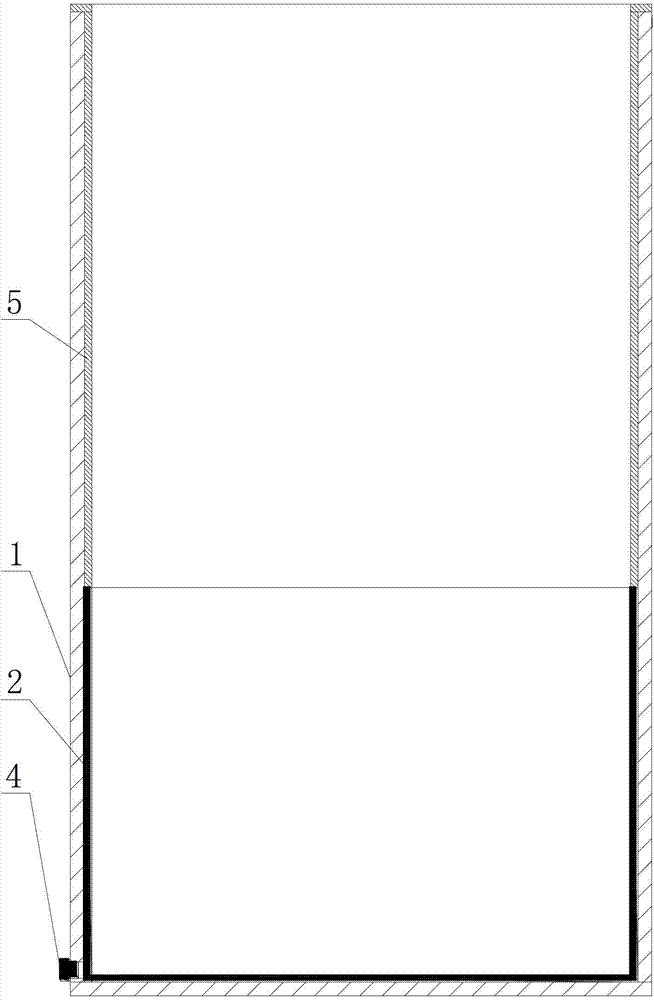

[0039] Such as figure 2 As shown, an oil barrel includes an oil barrel body 1, and the oil barrel also includes an air bag 2, the wall of the air bag 2 is attached to the inner side wall and the bottom wall of the oil barrel body 1, and the air bag 2 The sac opening is fixed on the top of the oil barrel body 1 by a fixing device, and an air hole is arranged at the bottom of the oil barrel body 1, and the air hole is sealed by an air hole plug 4.

[0040] There is an inflatable space between the wall of the air bag 2 and the inner side wall and the bottom wall of the oil drum body 1 .

[0041] The airbag 2 is a whole made of polyester fiber.

[0042] The fixing device is a fixing ring 5, and the fixing ring fixes the pocket opening of the air bag and the top of the inner side wall of the oil drum body together.

[0043] The air hole plug 4 is a silk plug.

[0044] Such as image 3 with Figure 4 As shown, a kind of oil pumping support for the oil drum of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com