Trimming-free novel flexible foam rubber and plastic heat insulation product and preparation method thereof

A kind of product and heat insulation technology, which is applied in the direction of sheet/board, building components, etc., can solve the problems of poor vacuum water absorption and thermal conductivity, non-reusability, high production cost, etc., achieve low vacuum water absorption and thermal conductivity, reduce glue Material waste, good foaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Ingredients: Accurately weigh the required raw materials according to the formula requirements of the new flexible foam rubber and plastic insulation products without trimming.

[0051] 2. Internal mixing and open refining: the raw materials are separately internally mixed and opened, and rolled into raw material films for later use.

[0052] (1) Weigh nitrile rubber NBR: 8.4kg, talcum powder: 6.4kg, polyethylene glycol PEG: 0.5kg, antioxidant 4020: 0.2kg, chlorinated paraffin CLP: 20kg, zinc borate: 4kg, paraffin: 0.9 kg, Sb 2 o 3 : 2kg, Al(OH) 3 : 16kg, epoxy soybean oil ADDA: 1kg, anti-aging agent RD: 0.1kg, carbon black: 0.4kg, polyvinyl chloride PVC: 9kg, chlorinated polyvinyl chloride CPVC: 10kg put it in the internal mixing room of the internal mixer and output it material. After mixing and slicing through the open mill, it is the No. 1 material. The temperature in the internal mixing room of the internal mixer is 140°C and the material is discharged. The ...

Embodiment 2

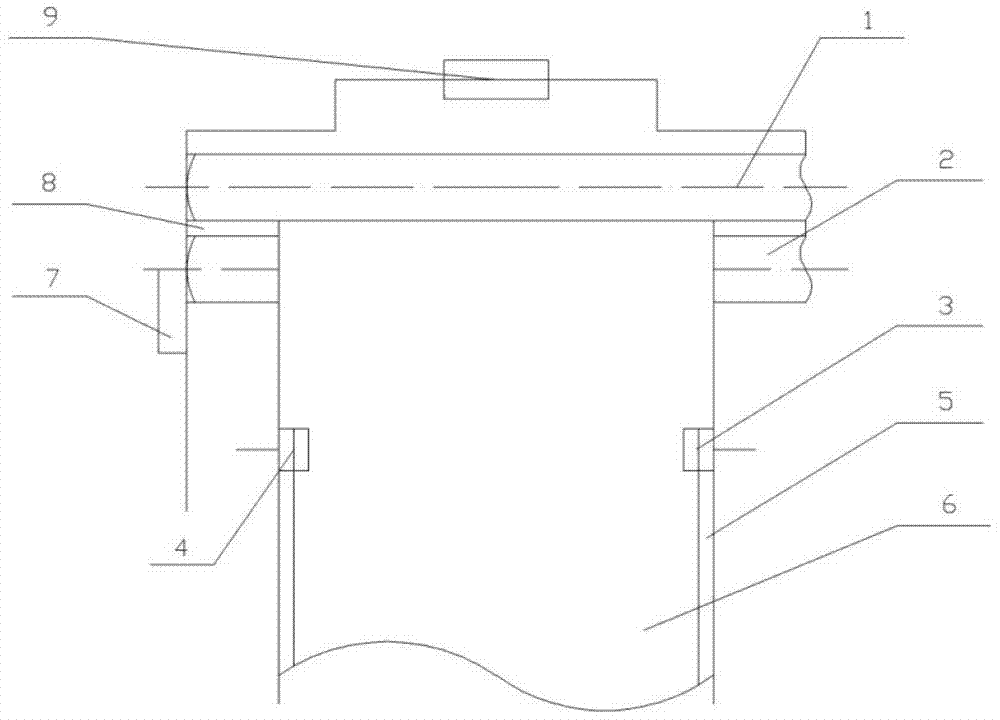

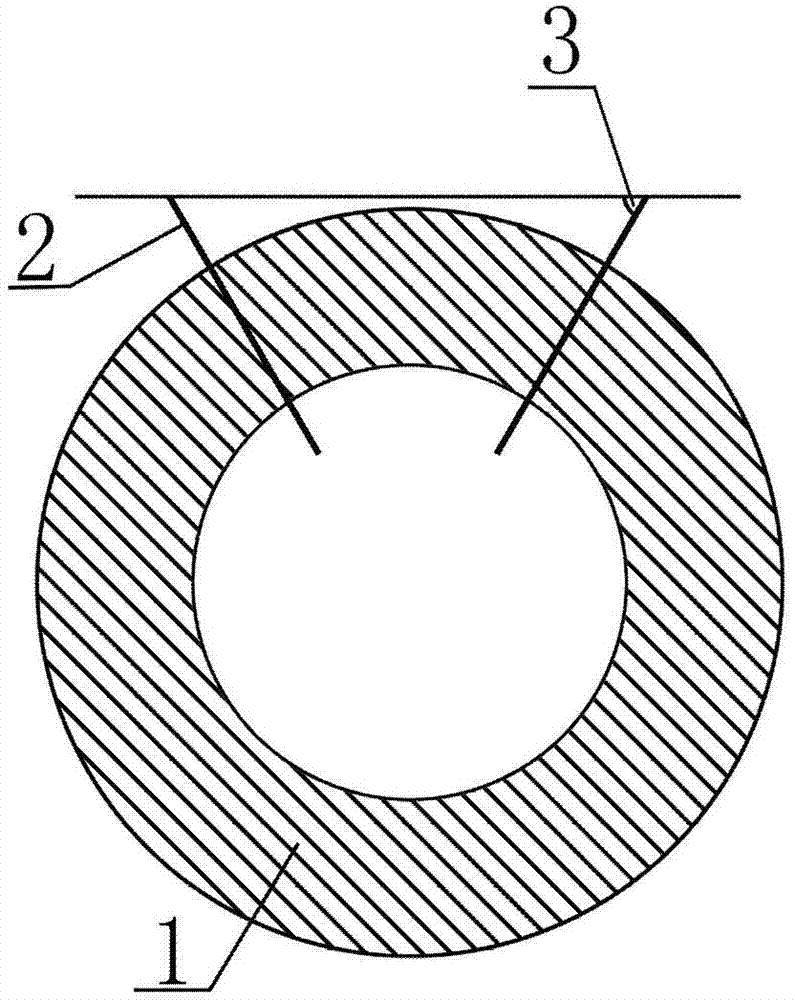

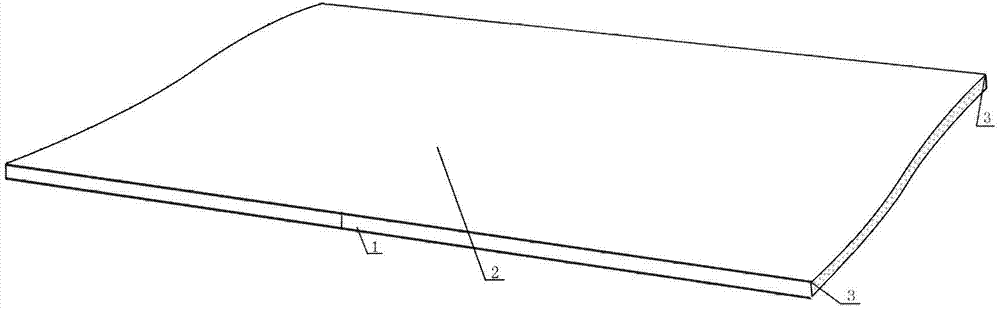

[0068] The method of Example 1 is used to prepare a new type of flexible foam rubber and plastic thermal insulation product. The difference is that the rubber strip in step 2 is fed into the extruder, and rolled by the upper roll 1 and the lower roll 2 of the multi-roll calender to prepare the thickness of the film. 10mm. According to the width of the final product, adjust the position of the flat die cutters 3 and 4. After the extruded flat film is cut by the cutters 3 and 4, the remaining material 5 after cutting is recycled and reused, and then shaped after cutting. Material 6 width is 500mm. Residual material 5 is recycled through residual material recycling device 9, and the shaped film 6 is transported to the foaming furnace.

[0069] The obtained novel flexible foam rubber and plastic insulation product has a width of 1500 mm and a thickness of 30 mm. The error between the thickness of the side of the product and the flatness of the product surface is 1mm. The vertic...

Embodiment 3

[0072] The method of Example 1 is used to prepare a new type of flexible foam rubber and plastic thermal insulation product. The difference is that the rubber strip in step 2 is fed into the extruder, and rolled by the upper roll 1 and the lower roll 2 of the multi-roll calender to prepare the thickness of the film. 15mm. According to the width of the final product, adjust the position of the flat die cutters 3 and 4. After the extruded flat film is cut by the cutters 3 and 4, the remaining material 5 after cutting is recycled and reused, and then shaped after cutting. Material 6 width is 500mm. Residual material 5 is recycled through residual material recycling device 9, and the shaped film 6 is transported to the foaming furnace.

[0073] The obtained novel flexible foam rubber and plastic insulation product has a width of 1500 mm and a thickness of 45 mm. The error between the thickness of the side of the product and the flatness of the product surface is 1mm. The vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com