Iodine vapor distributing device with on-line iodine function

A technology of iodine vapor and carrier gas, which is applied in gas and gas/steam mixing, mixer accessories, climate sustainability, etc. It can solve the problem of limited gas filling in steel cylinders, inability to work continuously for a long time, and no mention of online iodine addition, etc. problem, to achieve the effect of reducing the volume and weight of the device, continuous and stable supply for a long time, and reducing the initial iodine loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

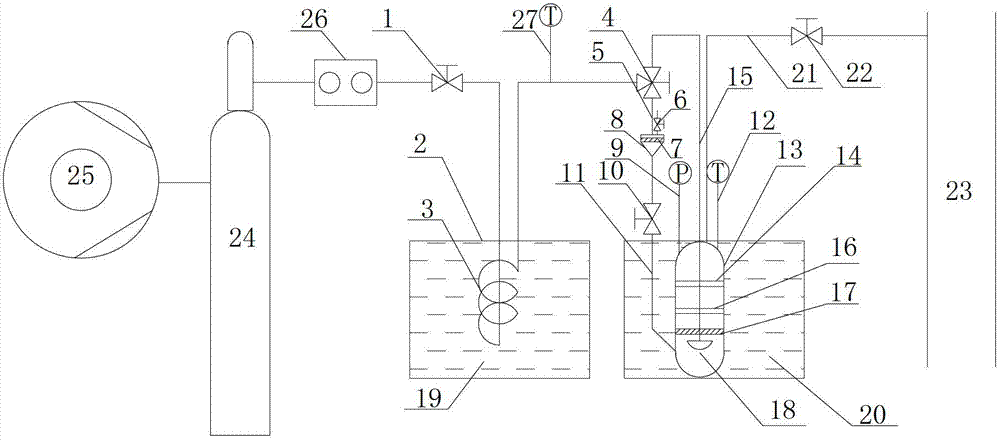

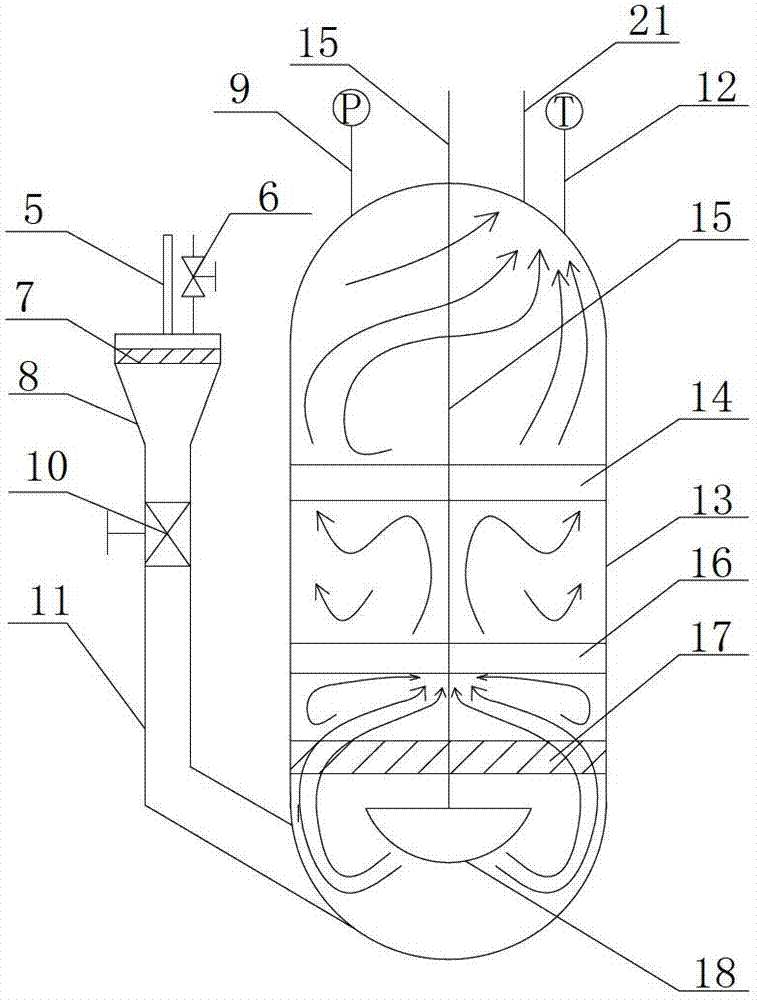

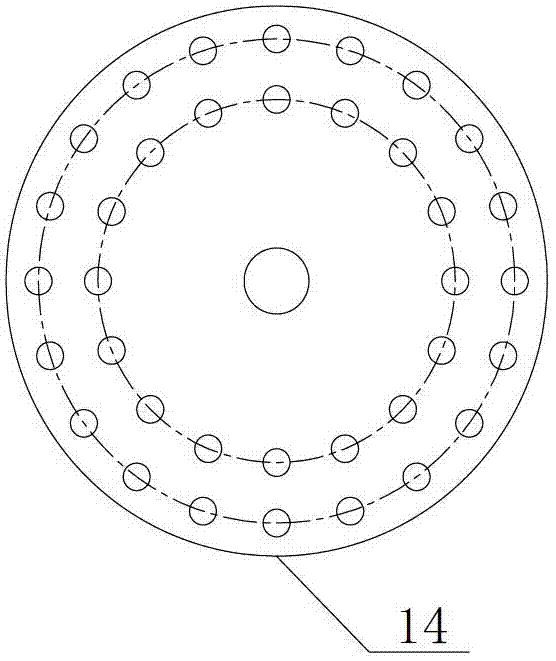

[0026] The present invention will be further described below with reference to accompanying drawing

[0027] like figure 1 As shown, an iodine vapor distribution device capable of adding iodine online is composed of an iodine vapor generating system, a carrier gas preheating system, an online iodine adding system, and pipes and valves connecting each device. The air compressor 25 is connected to the gas cylinder 24, the outlet of the gas cylinder is connected to the flowmeter 26, the flowmeter 26 is connected to the needle valve 1, one end of the spiral tube 3 is connected to the needle valve 1, and the other end is connected to the three-way valve 4 , the other two ends of the three-way valve are respectively connected with the air intake pipe 15 and the balance air pipe 5, the other end of the air intake pipe 15 is connected to the iodine vapor generator, and the other end of the balance air pipe 5 is connected to the charging system. Before the system runs, the air compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com