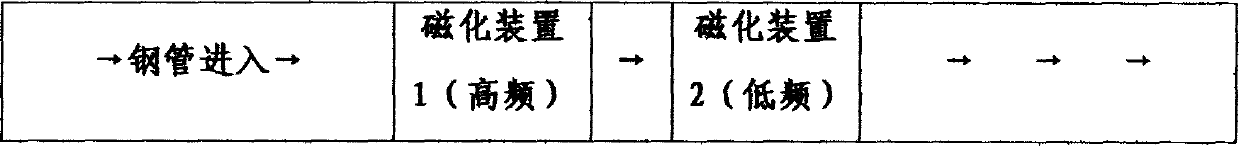

Eddy current high/low-frequency compound detection equipment for seamless steel tubes

A composite detection and seamless steel pipe technology, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of difficult identification and detection sensitivity, reduce the risk of missed detection, improve the detection effect and The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Combine below figure 2 and one The present invention is further described by the following embodiments:

[0027] A seamless steel pipe eddy current high-low-frequency compound testing equipment, including an electric control system, front and rear roller tables, a positioning and pressing wheel device, a three-roller centering device, a lifting device, a magnetization device, a flaw detection instrument, a demagnetizer and a blanking rack.

[0028] The electric control system is installed in a separate electrical cabinet to control the steel pipe transmission of the flaw detection equipment, realize automatic loading and unloading of steel pipes, sorting, defect signal alarm, and enable the equipment to complete automatic flaw detection, and is equipped with manual and automatic control;

[0029] The main electrical components of the electric control system include frequency converters and programmable controllers, and filter combinations are used for anti-interferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com