Adapter connecting spiral lobe compressor and motor

A technology for connecting screws and compressors, used in couplings, mechanical equipment, rigid shaft couplings, etc., can solve the problems of difficult work and long time, to ensure safe use, reduce connection distance, and ensure The effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

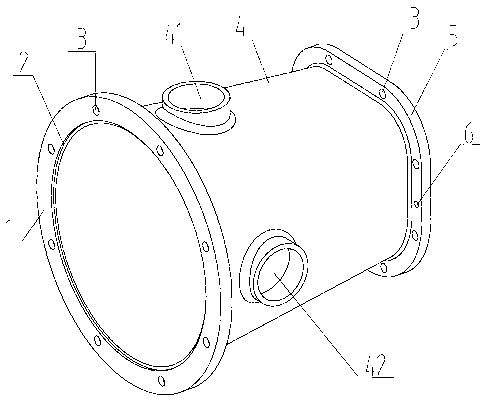

[0010] Such as figure 1 The principle diagram of the present invention is shown, and the present invention is composed of the motor end flange (1) connected with the compressor end flange (5) through the intermediate body (4); wherein, the motor end flange (1 ) is formed with motor positioning slots (2) and bolt holes (3), the intermediate body (4) is formed with air vents (41) and observation ports (42), and the compressor end flange (5 ) with compressor positioning pin holes (6) and bolt holes (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com