A dual-drive spindle control system for an oil-free dry vacuum pump

A dry vacuum pump and control system technology, applied in the direction of machines/engines, etc., can solve the problems of difficulty in gear processing, difficulty in controlling the cost of gear lubricants, high working noise of oil-free vacuum pumps, and affecting the life of oil-free vacuum pumps, etc., to achieve local and Remote control, high precision position control, and the effect of improving the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The scheme of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

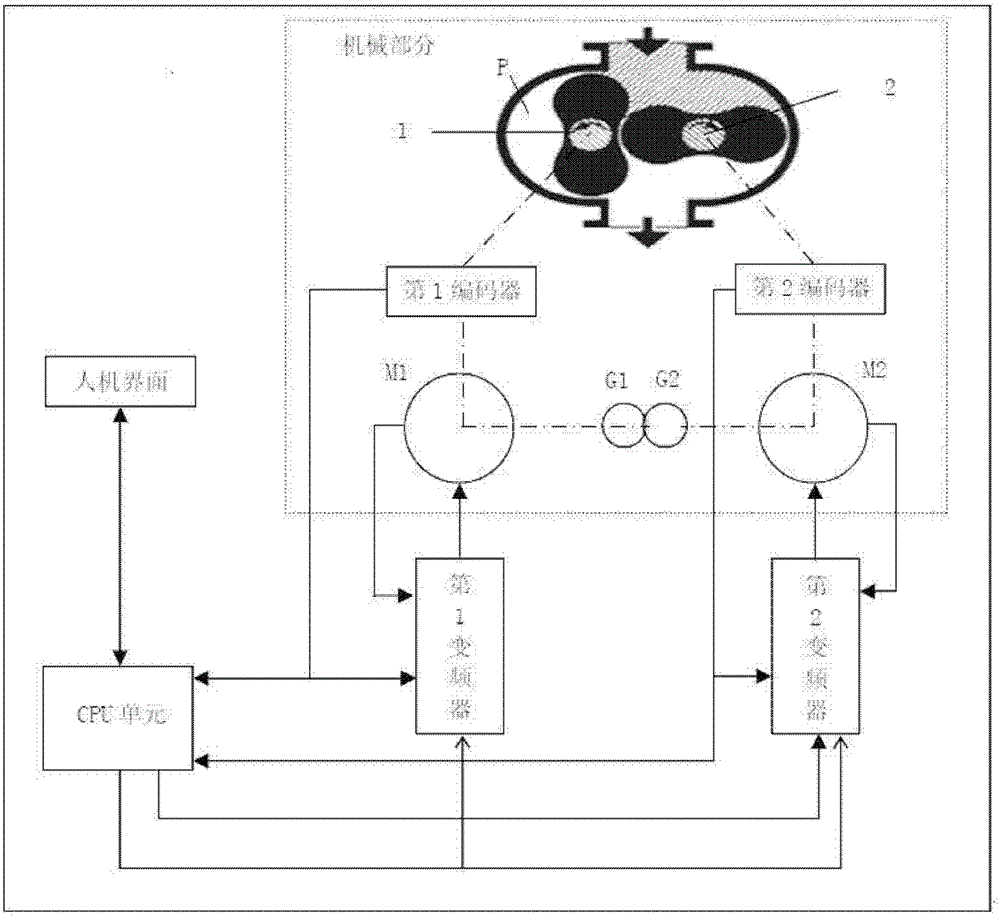

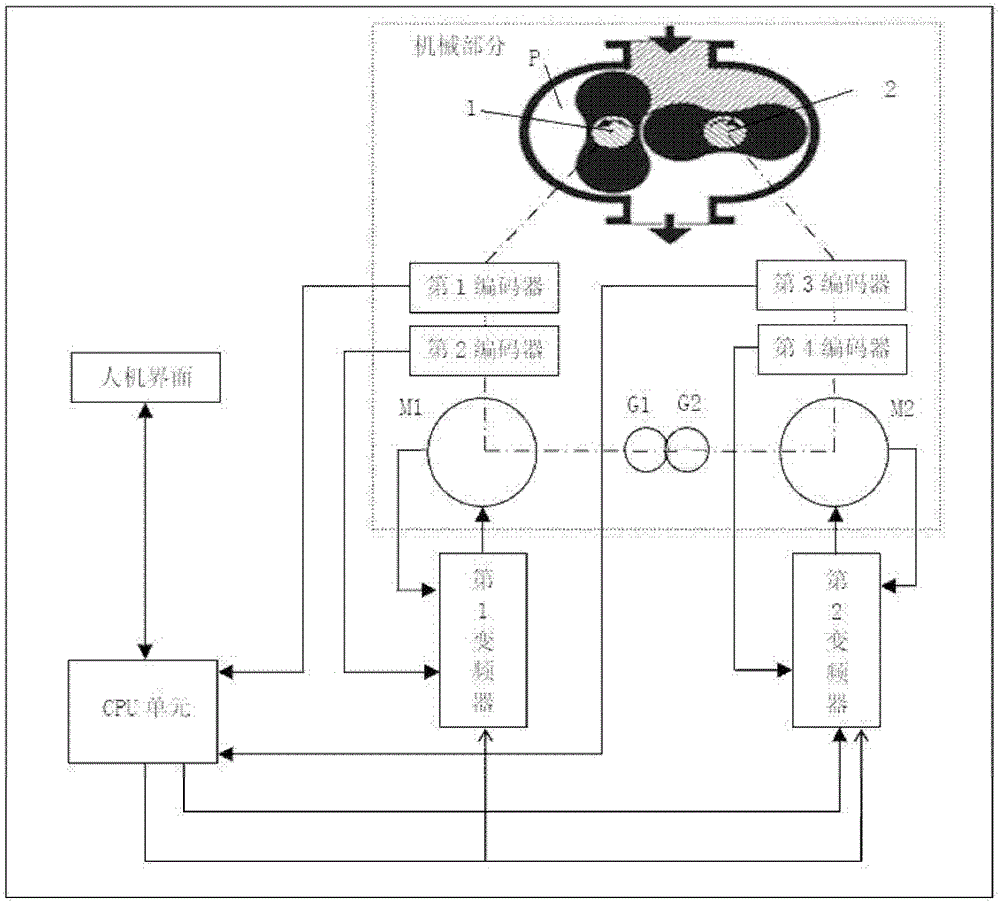

[0028] like figure 1 , 4 Shown is a schematic structural diagram and a schematic circuit diagram of the first control system of the present invention. 1. A dual-drive spindle control system for an oil-free dry vacuum pump, which includes a mechanical part of a dual-axis oil-free dry vacuum pump, characterized in that: a motor control part is also added; wherein, the dual-axis oil-free dry vacuum pump P Each shaft 1 and 2 is respectively equipped with a motor, a positioning gear and an encoder. The motor control part connects the collected and output pulse data signals to the input terminals of the AC frequency converter and the CPU unit at the same time through the encoder installed on the motor shaft. , to achieve closed-loop control of the motor speed.

[0029] The electric control part includes the first and second AC frequency converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com