Method for harvesting dunaliella salina

A harvesting method and salina technology, applied in the field of microalgae, can solve the problems of high equipment cost, high energy consumption, product loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

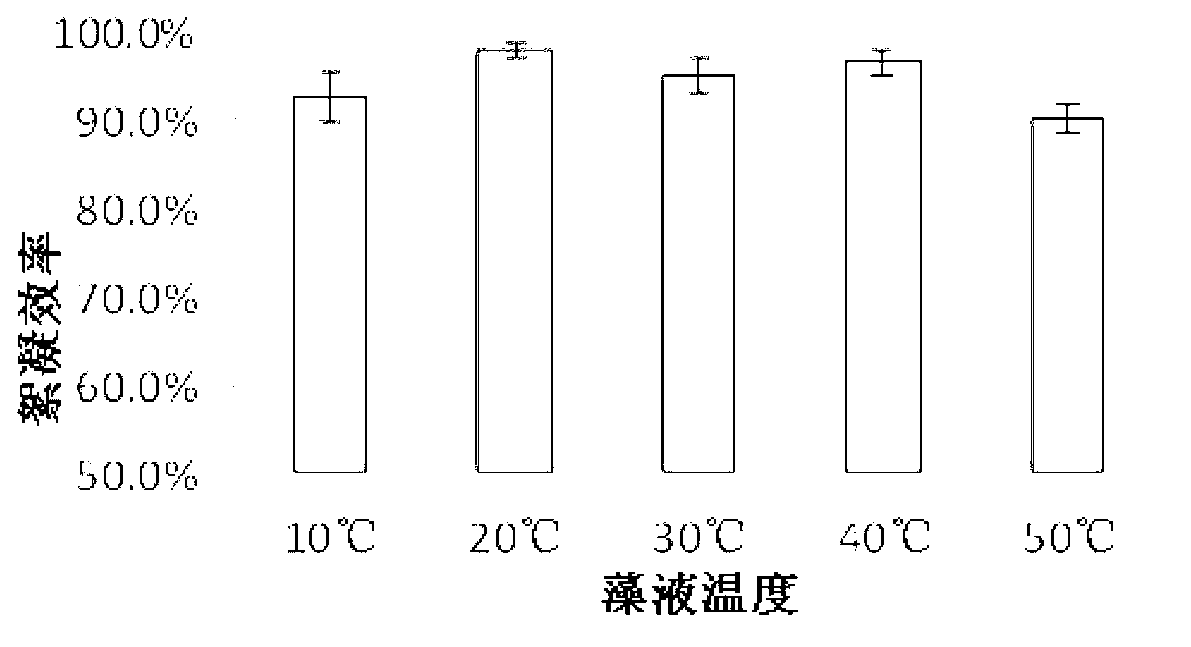

Method used

Image

Examples

Embodiment 1

[0027] After 20 days of winter salina culture, the algal cell density reached 3.32×10 6 cells / mL, the salinity of the algae solution is 134‰, the temperature of the algae solution is 15°C, and the pH is 8.2. Add PAC to reach a final concentration of 100mg / L. After stirring evenly, let stand for 41 h and then remove the supernatant. The algae mud was collected and the flocculation efficiency was 92.2%.

Embodiment 2

[0029] After 20 days of winter salina culture, the algal cell density reached 5.18×10 6 cells / mL, the salinity of the algae solution is 107‰, the temperature of the algae solution is 15°C, and the pH is 7.6. Add PAC to reach a final concentration of 150mg / L. After stirring well, let it stand for 24 hours and then remove the supernatant. The algae mud was collected and the flocculation efficiency was 93.6%.

Embodiment 3

[0031] After 12 days of summer salina cultured, the algal cell density reached 2.75×10 6 cells / mL, the salinity of the algae solution is 220‰, the temperature of the algae solution is 30°C, and the pH is 8.5. Add PAC to reach a final concentration of 130mg / L. After stirring well, let it stand for 24 hours and then remove the supernatant. The algae mud was collected and the flocculation efficiency was 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com