Polyolefin wood-plastic composite material and preparation method thereof

A wood-plastic composite material and polyolefin technology, applied in the field of polyolefin wood-plastic composite material and its preparation, can solve the problems of reducing the mechanical properties of polyolefin wood-plastic composite material, only a few percent improvement, and limited improvement effect. , to achieve the effect of improving melt extrusion efficiency and product output, good lubrication effect, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

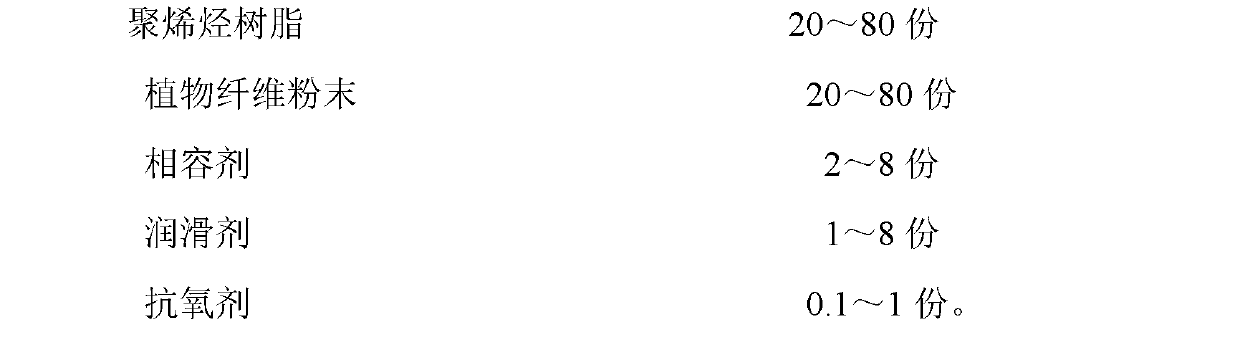

Method used

Image

Examples

Embodiment 1

[0033]First, 80 parts of recycled polypropylene resin, 20 parts of bamboo powder with a particle size of 30 meshes dried to a moisture content of less than 1%, 2 parts of maleic anhydride grafted polypropylene, 1 part of pentaerythritol tetrabenzoate, and 1010 parts of antioxidant Add 0.1 part of the compound composed of antioxidant 168 into a high-speed mixer and pre-mix evenly, then put the pre-mixed material in a twin-screw extruder, extrude and granulate at a temperature of 160-190 ° C, and then make the prepared The pellets are placed in a twin-screw extruder, and continue to be extruded at a temperature of 160-190°C to obtain a polyolefin wood-plastic composite material.

[0034] The average torque of the obtained wood-plastic composite material is 3.2N.M, the bending strength is 30.1MPa, and the bending modulus is 0.99×10 4 MPa, the water absorption rate is 1.62%.

Embodiment 2

[0036] The materials used in this example are: 33.5 parts of recycled polypropylene resin, 60 parts of wood powder with a particle size of 40 meshes dried to a moisture content of less than 1%, 2 parts of maleic anhydride grafted polypropylene, and 4 parts of pentaerythritol tetrabenzoate , 0.5 part of the compound of antioxidant 1010 and antioxidant 168, all the other process steps and conditions are exactly the same as in Example 1, omitted.

[0037] The average torque of the obtained wood-plastic composite material is 3.4N.M, the bending strength is 36.6MPa, and the bending modulus is 1.32×10 4 MPa, the water absorption rate is 1.53%.

Embodiment 3

[0039] The materials used in this example are: 33.5 parts of recycled polypropylene resin, 60 parts of wood powder with a particle size of 60 meshes dried to a moisture content of less than 1%, 3 parts of maleic anhydride grafted polypropylene, and 2 parts of pentaerythritol tetrabenzoate , 1 part of pentaerythritol stearate, 0.5 part of the compound of antioxidant 1010 and antioxidant 168, all the other process steps and conditions are exactly the same as in Example 1, omitted.

[0040] The average torque of the obtained wood-plastic composite material is 4.7N.M, the bending strength is 36.6MPa, and the bending modulus is 1.26×10 4 MPa, water absorption rate is 4.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com