Novel accelerant and curing agent, preparation method and application thereof

A technology of accelerator and curing agent, used in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as unhelpful curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

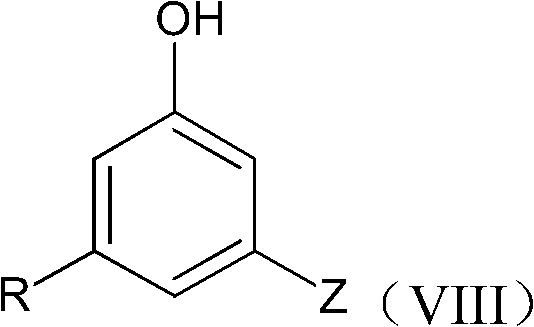

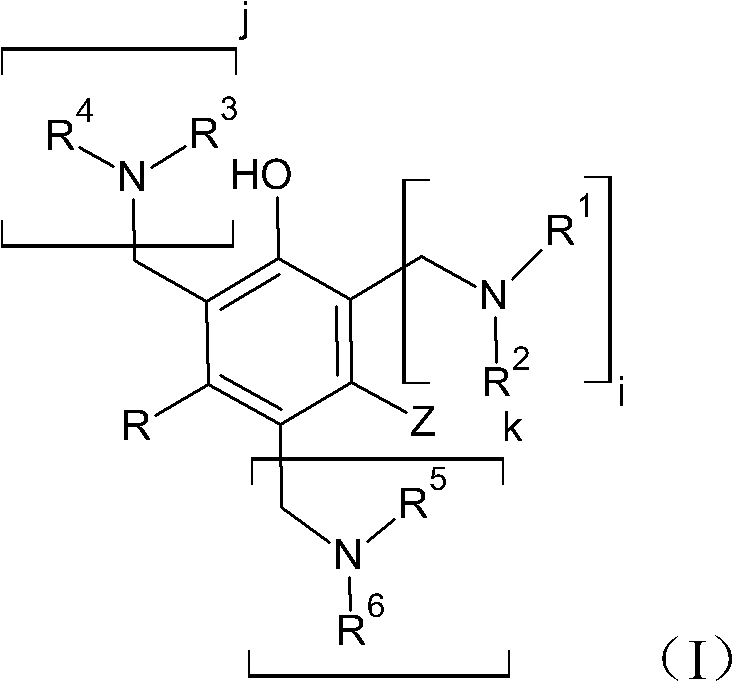

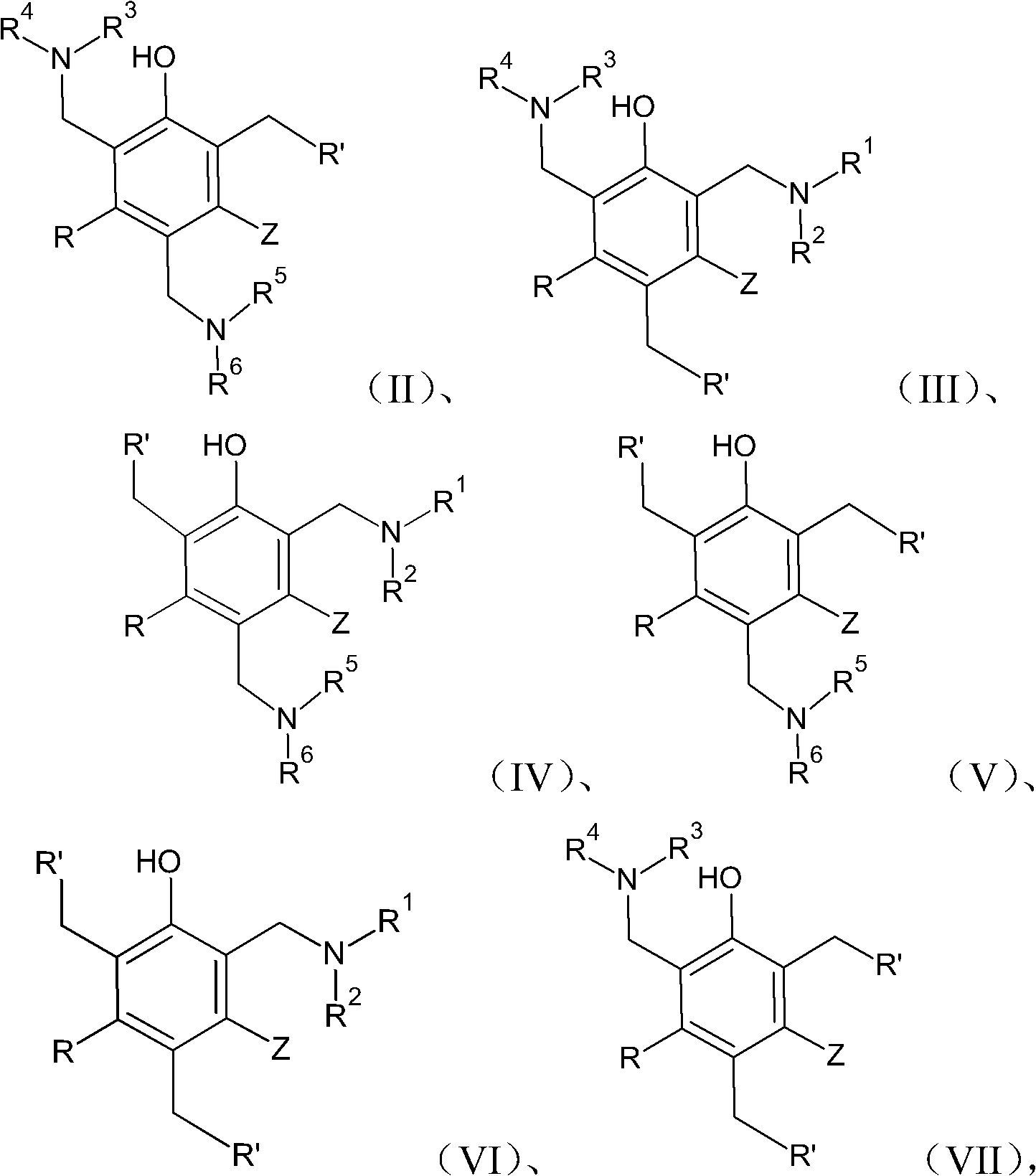

Method used

Image

Examples

Embodiment 1

[0070] Example 1: Mannich condensation reaction of cardanol, para-formaldehyde and dimethylamine to synthesize dimethylaminomethyl cardanol

[0071] Prepare a 1-liter four-pot equipped with a thermometer, a Teflon stirrer, and a Dean-Stark h-shaped water trap. A 4-necked round bottom flask; wherein the Dean-Stark H-type water separator is connected to a condenser and a nitrogen gas supplying valve is connected to the 4-necked round bottom flask . The four-neck round bottom flask was filled with 300 grams of cardanol (about 1 mole) and 115 grams of dimethylamine (about 1 mole) at a concentration of 40% by weight, and was placed in a fume hood (ventilation hood) with Stirring is carried out under the environment of dry nitrogen, and the temperature of this four-neck round bottom flask is controlled at 50 ℃ for about 1 hour, then 75 grams of formalin (formalin) with a concentration of 40% by weight (about 1.0 mole) is added slowly into a four-neck round bottom flask. The afore...

Embodiment 2

[0073] Example 2: Mannich condensation reaction of cardanol, p-formaldehyde and diethylamine to synthesize bis(diethylaminomethyl)cardanol

[0074] Prepare a four-neck round bottom flask with a capacity of 1 liter equipped with a thermometer, a Teflon stirrer, a Dean-Stark h-type water separator; where the Dean-Stark h A water separator was connected to a condenser and a nitrogen supply valve was connected to a four-neck round bottom flask. The four-neck round bottom flask is filled with 300 grams of cardanol (about 1.0 moles) and 148 grams of diethylamine (about 2.0 moles) with a concentration of 99% by weight, and has an environment of dry nitrogen in a fume hood Under stirring, the temperature of the four-necked round-bottomed flask was controlled at 65°C for about 30 minutes, and then 150 grams of formalin with a concentration of 40% by weight (about 2.0 moles) was slowly added to the four-necked round-bottomed flask . The aforementioned substances were slowly heated to ...

Embodiment 3

[0076] Embodiment 3: Cardanol, p-formaldehyde and diethylamine carry out Mannich condensation reaction to synthesize bis(diethylaminomethyl) cardol (bis(diethylaminomethyl)cardol)

[0077] Prepare a four-neck round bottom flask with a capacity of 1 liter equipped with a thermometer, a Teflon stirrer, a Dean-Stark h-type water separator; where the Dean-Stark h A water separator was connected to a condenser and a nitrogen supply valve was connected to a four-neck round bottom flask. The four-neck round bottom flask is filled with 316 grams of cardanol (about 1.0 moles) and 148 grams of diethylamine (about 2.0 moles) at a concentration of 99% by weight, and is placed in a fume hood with dry nitrogen. Stirring under ambient conditions, the temperature of the four-necked round-bottomed flask was controlled at 65°C for about 30 minutes, and then 150 grams of formalin with a concentration of 40% by weight (about 2.0 moles) was slowly added to the four-necked round-bottomed flask mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com