Method of preparing bio-organic fertilizer by utilizing waste residue caused in process of producing starch from cassava

A technology for bio-organic fertilizer and starch processing, applied in the preparation of organic fertilizer, bio-organic part treatment, organic fertilizer and other directions, can solve the problems of restricting the utilization of cassava residues, pollute the environment, waste resources, etc., and improve the micro-ecological environment. , the effect of improving comprehensive benefits, improving quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

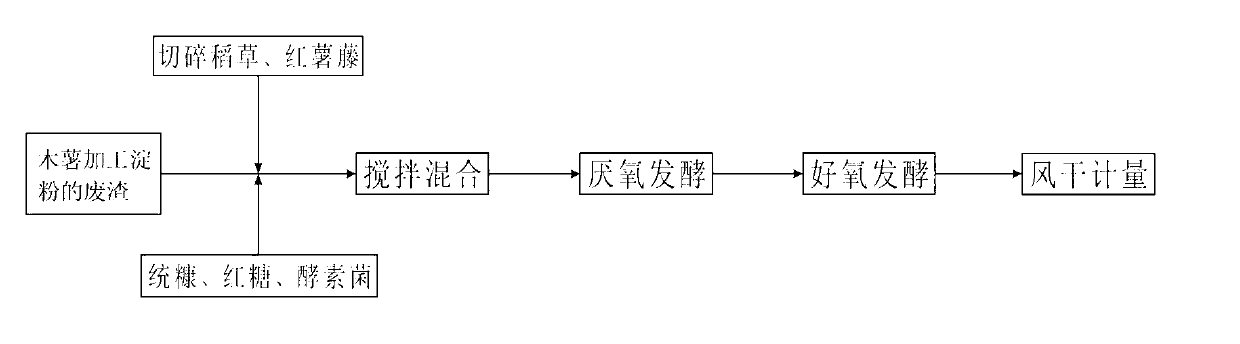

Method used

Image

Examples

Embodiment

[0025] A cassava starch processing enterprise in Guangxi uses the fresh waste residue produced by cassava processing starch to prepare bio-organic fertilizer. The ratio of raw materials is: cassava starch processing waste residue 72, bran 18, sweet potato vine 3, rice straw 6.7, enzyme bacteria 0.1, Brown sugar 0.2; Stir and mix the above raw materials for 12 minutes, and control the moisture content at 60%. After mixing, stack them in strips with a width of 2.5m and a height of 1.5m, and ferment for 2 days with anoxic fermentation; The piles were cooled for 1 day and then stacked for 25 days, during which time the piles were turned once; the piles were naturally air-dried until the moisture content was lower than 30%, and then measured and packaged to make more than 7,500 tons of finished bio-organic fertilizers, which are used for pollution-free, green and organic rice, Vegetables, fruits, etc. are planted.

[0026] According to the test, after applying 300-350kg / mu of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com