Laser welding composite material for solar collector

A composite material and laser welding technology, which is applied to the parts, anodic oxidation, and absorbing elements of solar collectors, can solve the problems that the efficiency is still improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] For the following description, it needs to be emphasized that the present invention is not limited to these embodiments, and therefore is not limited to all or more features in the described combination of features; in fact, every single sub-feature in any embodiment When separated from all other sub-features described together, whether it exists alone or in combination with any feature in another embodiment, it still has the meaning of the invention.

[0054] In the different figures, identical components, or in particular layers that perform the same function, are assigned the same reference symbols and are therefore generally only described once in the following text.

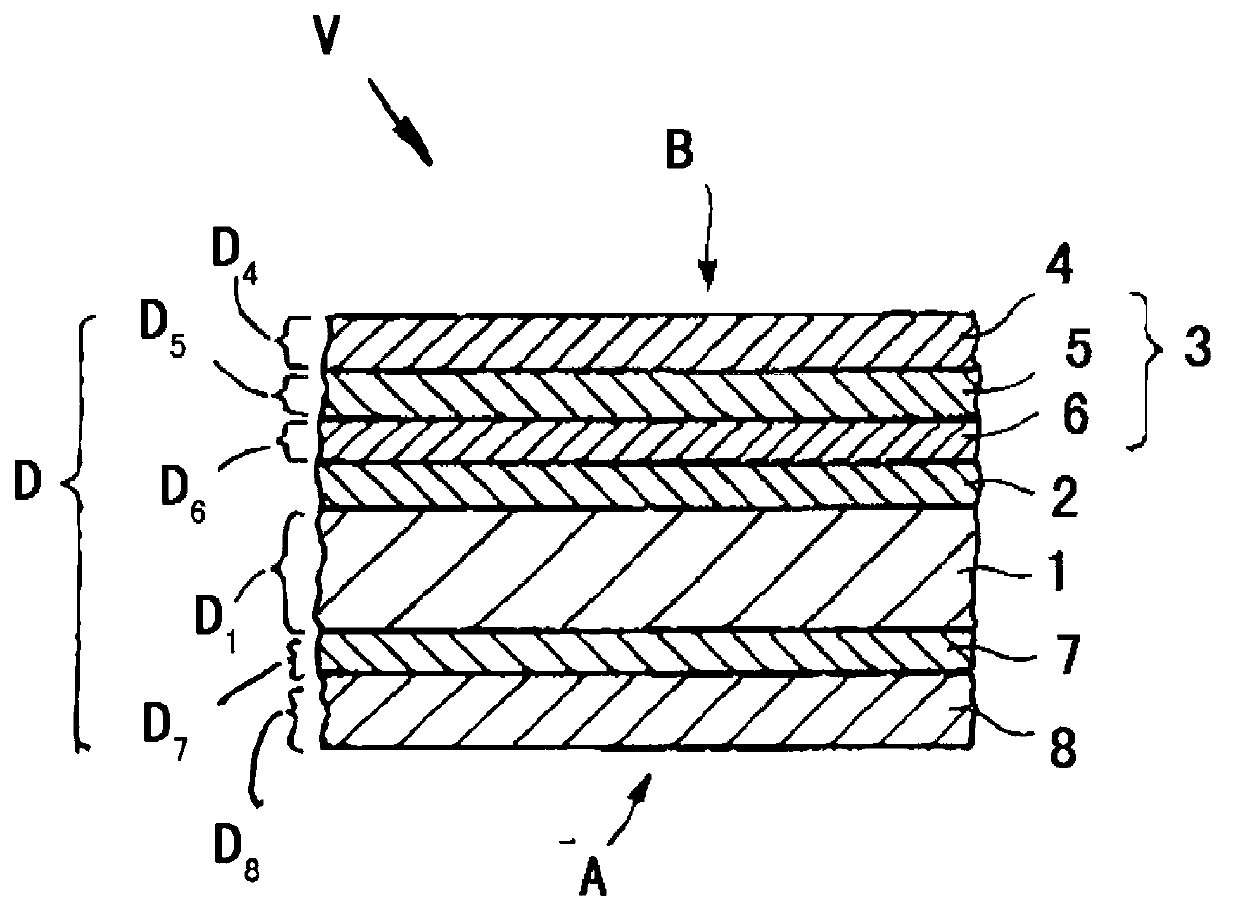

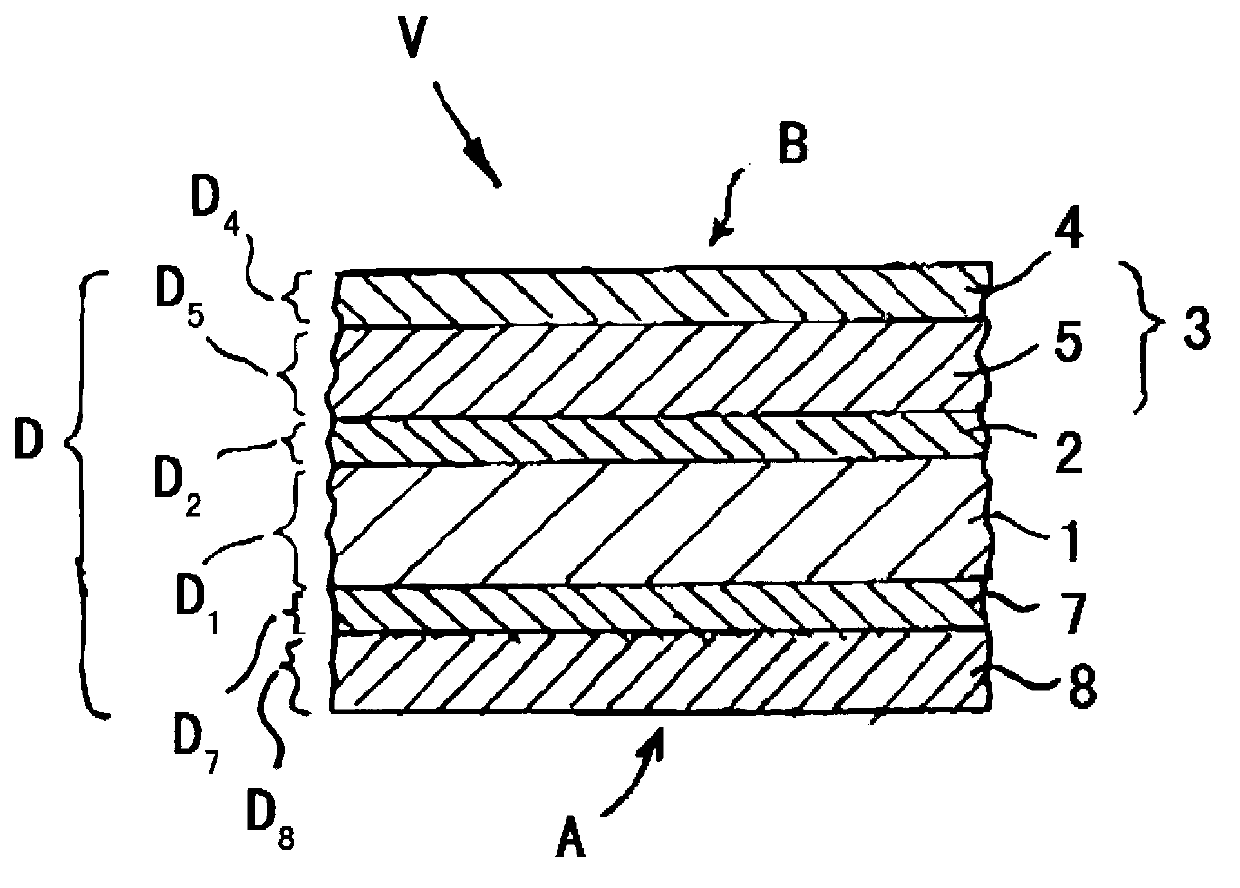

[0055] first as figure 1 As shown, a first embodiment of a laser-weldable composite material V according to the invention, which can be used in particular for the production of solar collector elements, comprises a metal base body 1 in the form of a strip. The base body has a first side A and a secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com