Fibrous membrane end surface electric heating sintering device

A technology of sintering device and fiber film bundle, which is applied in the direction of suction equipment, etc., can solve the problems of low production efficiency, reduce production cost, toxic residues, etc., and achieve the effect of realizing automatic control, reducing production costs, and eliminating toxic residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

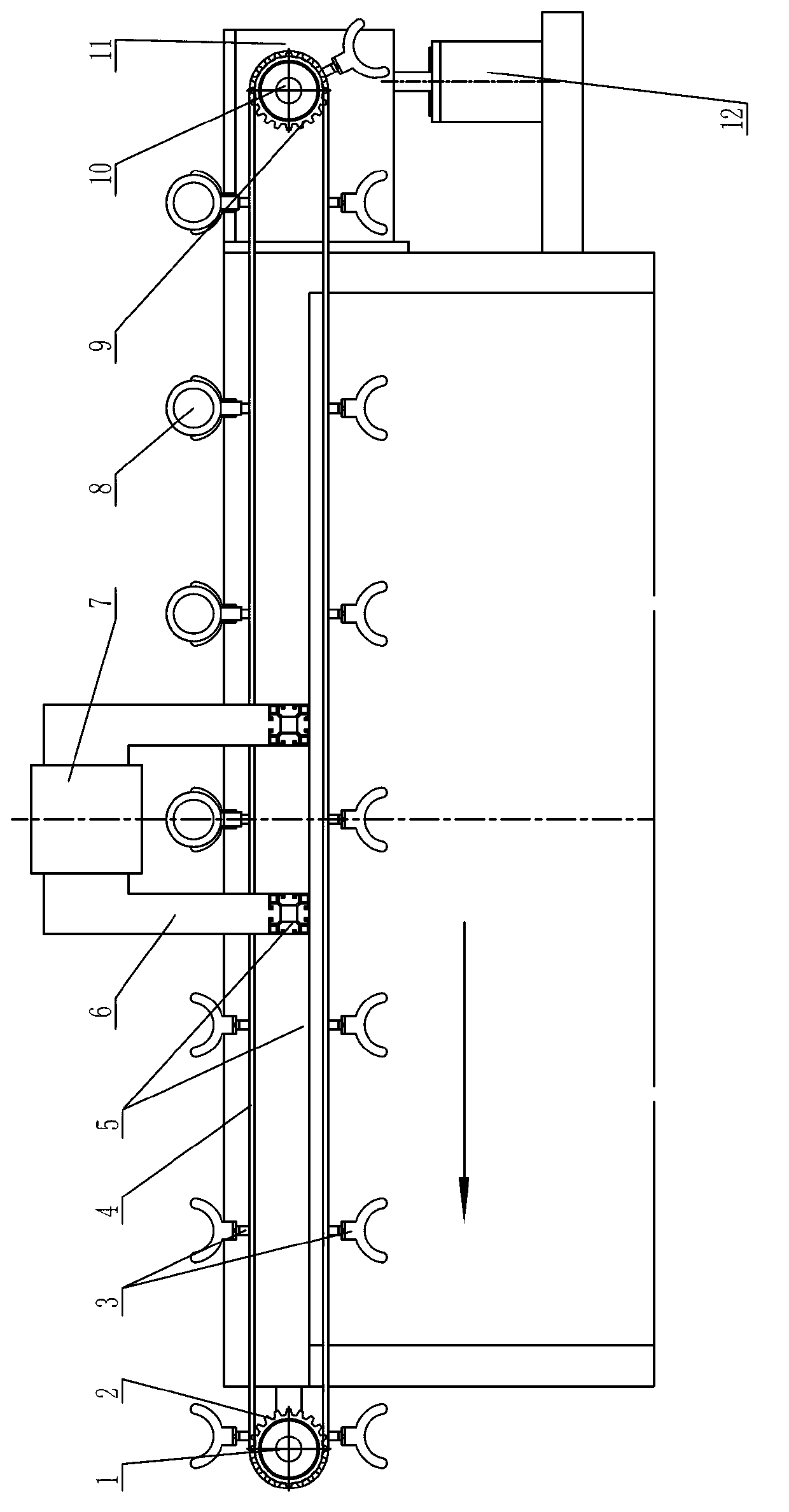

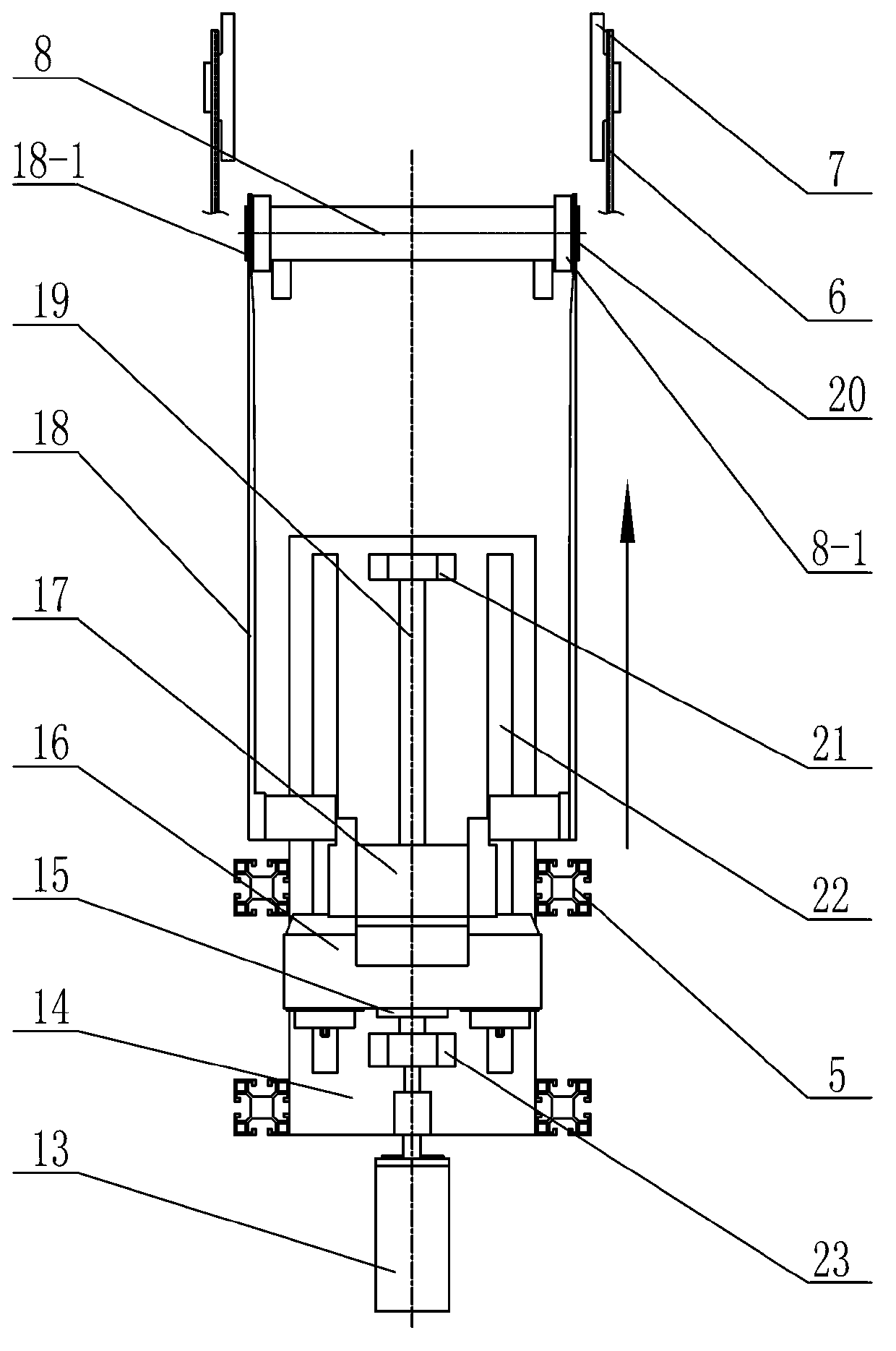

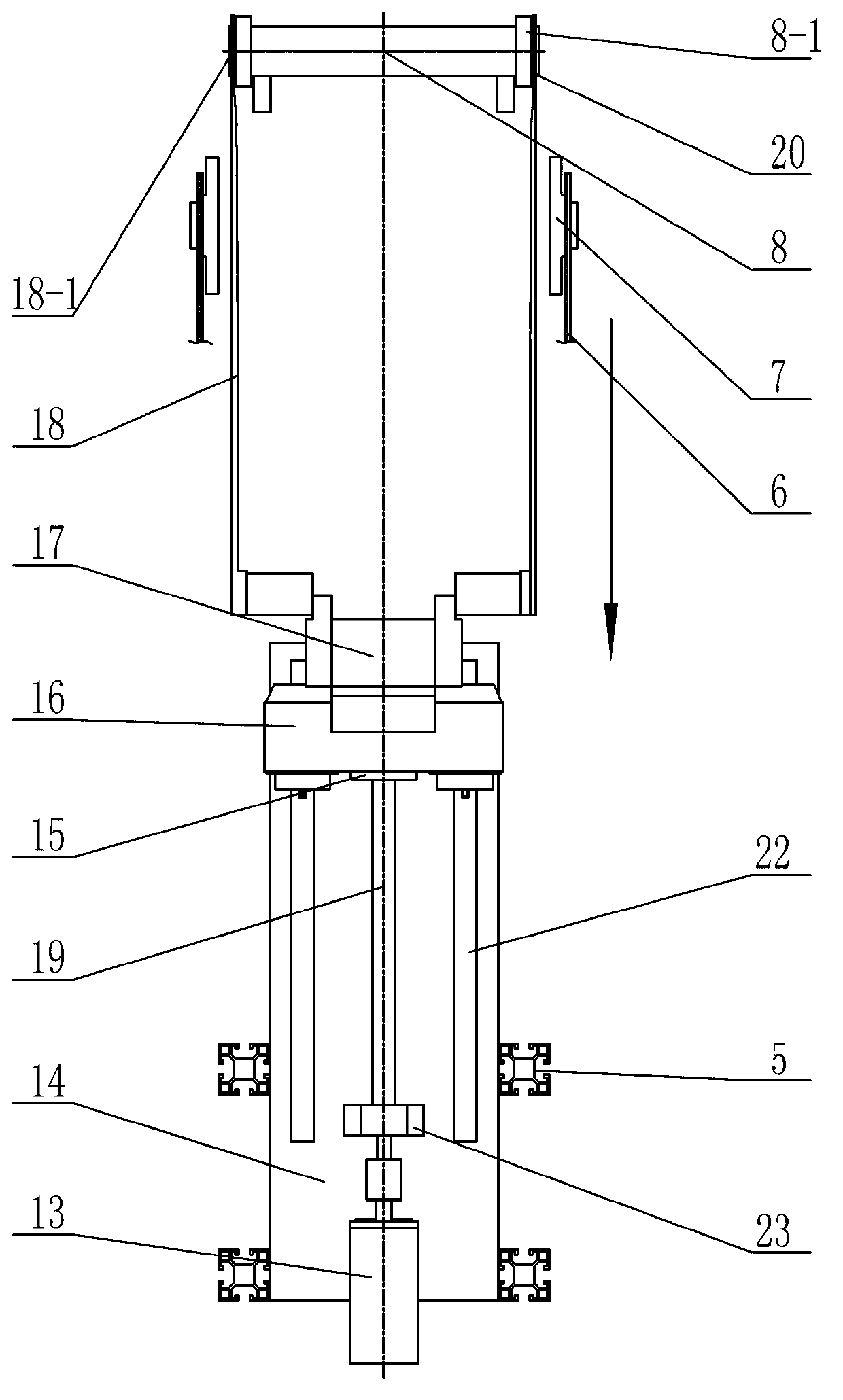

[0015] See Figure 1-2 As shown, the fiber membrane bundle end face electrothermal sintering device of the present invention includes a frame 5 and a conveying mechanism installed on the frame 5 for conveying the fiber membrane cylinder 8 inside, and installed on the frame 5 for clamping the cylinder The rubber ring on both sides of the body is sealed and the clamping and lifting mechanism is used to lift the cylinder body, and the heating mechanism is installed on the frame 5 to sinter and seal the end surface of the fiber film in the sealing process.

[0016] See figure 1 As shown, the conveying mechanism of the present invention includes a first servo motor 12, a driving sprocket 9, a driven sprocket 2, a transmission chain 4 and a pallet 3, the first servo motor 12 is connected with the driving shaft 10 through a reducer 11, and the driving shaft 10 Installed on one end of the frame 5, two driving sprockets 9 are installed on the driving shaft 10, the driven shaft 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com