Pincher-shaped extrusion stitching nail type meniscus front-rear corner stitching instrument

A technology of anterior and posterior angles and menisci, which is applied in the field of medical devices, can solve the problems of complicated device operation process, difficulty for young doctors to master, increase of infection complications, etc., and achieve the effect of simple device preparation, good hand feeling and less surgical side damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

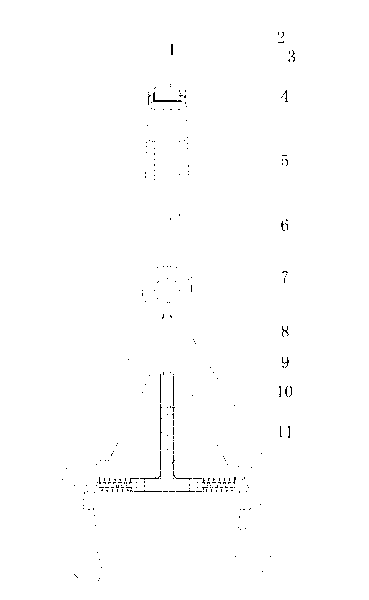

[0014] Such as figure 1 As shown, the present invention keeps the pliers mouth 1 in an open state and the spring 10 in a relaxed state before use, places the meniscus staple 3 on the staple fixing plate 4, and vertically passes the pliers mouth 1 through the damaged part of the front and rear corners of the meniscus With the aid of arthroscopic monitoring, determine the suture position, so that the meniscus is clamped between the two parts of the jaw 1, and the baffle 2 exceeds the meniscus damage gap. Press the handle, the piston squeezes the working medium 9 in the three-way piston hydraulic tube 7, and the pressure makes the push rod 5 drive the staple fixing plate 4 to move forward, pushing the meniscus staple 3 to the baffle plate 2, and the meniscus after meeting resistance The two tips of the staples 3 are bent in the forward direction to tightly bite the damaged gap of the meniscus to complete the suture of the anterior and posterior corners of the meniscus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com