Natural preservative and preparation method thereof

A natural preservative and a certain amount of technology, applied in the field of preservatives, can solve the problems of application limitation, narrow antibacterial spectrum and high cost, and achieve the effects of wide applicable objects, good antibacterial effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

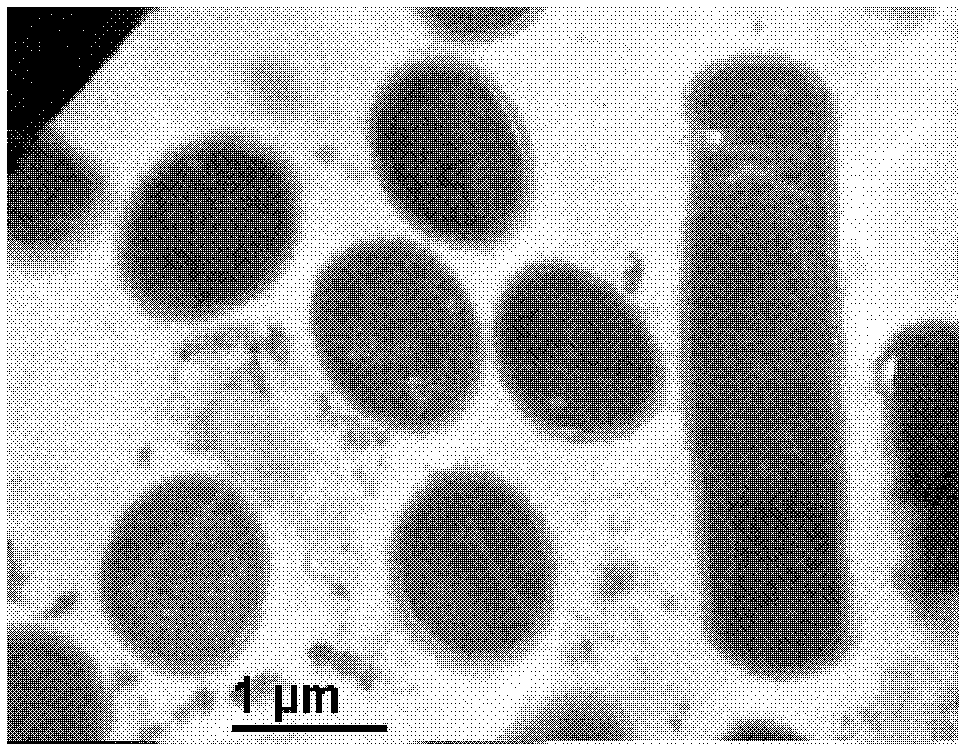

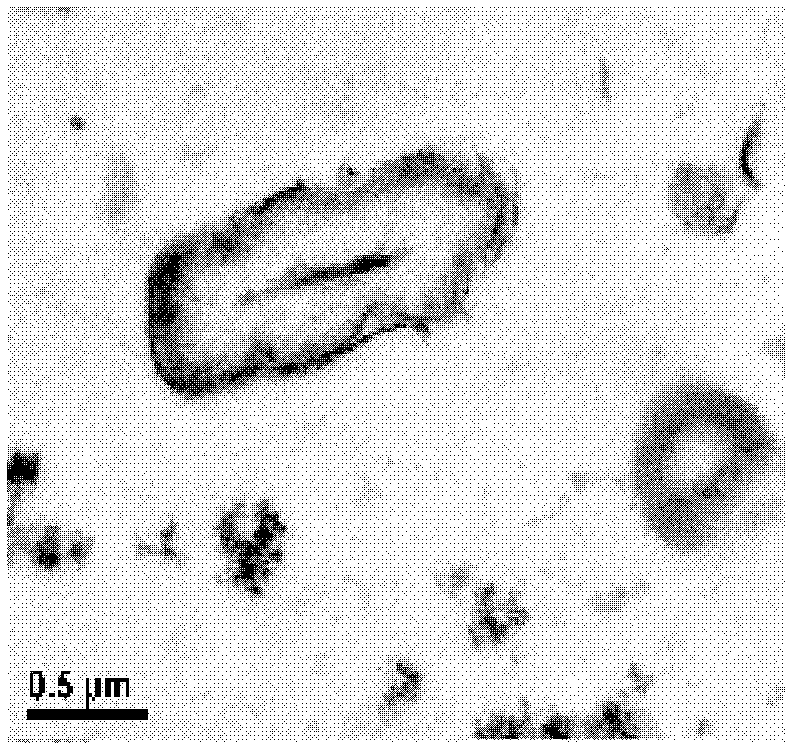

Image

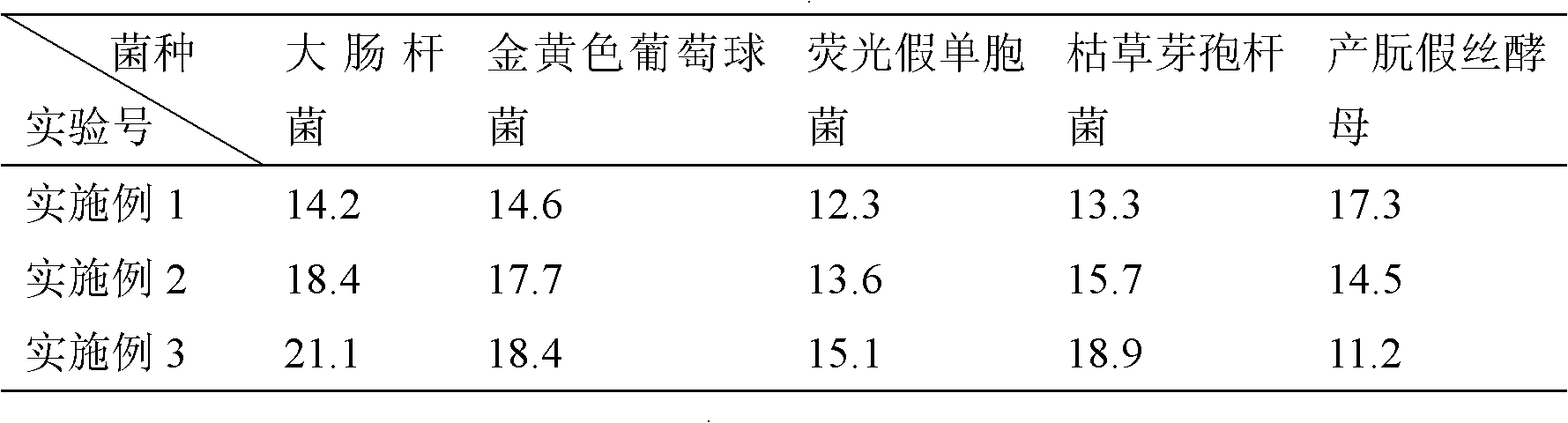

Examples

Embodiment 1

[0021] (1) Weigh 1 part of purple salvia miltiorrhiza, dry it at 60°C for 5 hours, and crush it with a pulverizer until it passes through a 40-mesh sieve, add 6 parts of 60% ethanol solution (that is, the mass ratio of red salvia miltiorrhiza to ethanol solution is 1:6), and heat it at room temperature at 20°C. After immersion and extraction for 3 hours, filter the extract with filter paper after the immersion, add 6 parts of 60% ethanol solution to the filter residue (i.e. purple salvia miltiorrhiza powder) and immerse at room temperature for 3 hours at 20°C, repeat the leaching for 3 times, and combine the extracts for 3 times. Put it in a rotary evaporator at 60°C and concentrate until the concentration of the extracted liquid is 50 mg / mL, that is, 1 mL of the extract is equivalent to 50 mg of the original drug.

[0022] (2) Weigh 1 portion of denuclear ebony, place it in a beater at 5000r / min for beating for 10 minutes, add distilled water in a mass ratio of 1:10, and place...

Embodiment 2

[0027] (1) Weigh 1 part of purple salvia miltiorrhiza, dry it at 70°C for 6 hours, crush it with a pulverizer to pass through a 40-mesh sieve, add 6 parts of 60% ethanol solution (that is, the mass ratio of red salvia miltiorrhiza to ethanol solution is 1:6), and heat it at room temperature at 20°C. After immersion and extraction for 4 hours, filter the extract with filter paper after immersion and contact, add 6 parts of 60% ethanol solution to the filter residue (i.e. purple salvia miltiorrhiza powder) and soak for 4 hours at room temperature at 20°C, repeat the extraction for 3 times, and combine the extracts for 3 times, Put it in a rotary evaporator at 60°C and concentrate until the concentration of the extracted liquid is 50 mg / mL, that is, 1 mL of the extract is equivalent to 50 mg of the original drug.

[0028] (2) Weigh 1 portion of denuclear ebony, place it in a beater at 5000r / min for beating for 10 minutes, add distilled water in a mass ratio of 1:20, and place the ...

Embodiment 3

[0033](1) Weigh 1 part of purple salvia miltiorrhiza, dry it at 80°C for 8 hours, and crush it with a pulverizer until it passes through a 40-mesh sieve, add 6 parts of 60% ethanol solution (that is, the mass ratio of red salvia miltiorrhiza to ethanol solution is 1:6), and heat it at room temperature at 20°C. After immersion and extraction for 5 hours, filter the extract with filter paper after immersion contact, add 6 parts of 60% ethanol solution to the filter residue (i.e. purple salvia miltiorrhiza powder) and soak for 5 hours at room temperature at 20°C, repeat the extraction for 3 times, and combine the extracts for 3 times, Put it in a rotary evaporator at 60°C and concentrate until the concentration of the extracted liquid is 50 mg / mL, that is, 1 mL of the extract is equivalent to 50 mg of the original drug.

[0034] (2) Weigh 1 portion of denuclear ebony, put it in a beater at 5000r / min for beating for 10 minutes, add distilled water in a mass ratio of 1:15, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com