High-frequency power supply device, plasma processing device and method for producing thin film

A high-frequency power supply device technology, applied in plasma, semiconductor/solid-state device manufacturing, circuits, etc., can solve difficult and unreachable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

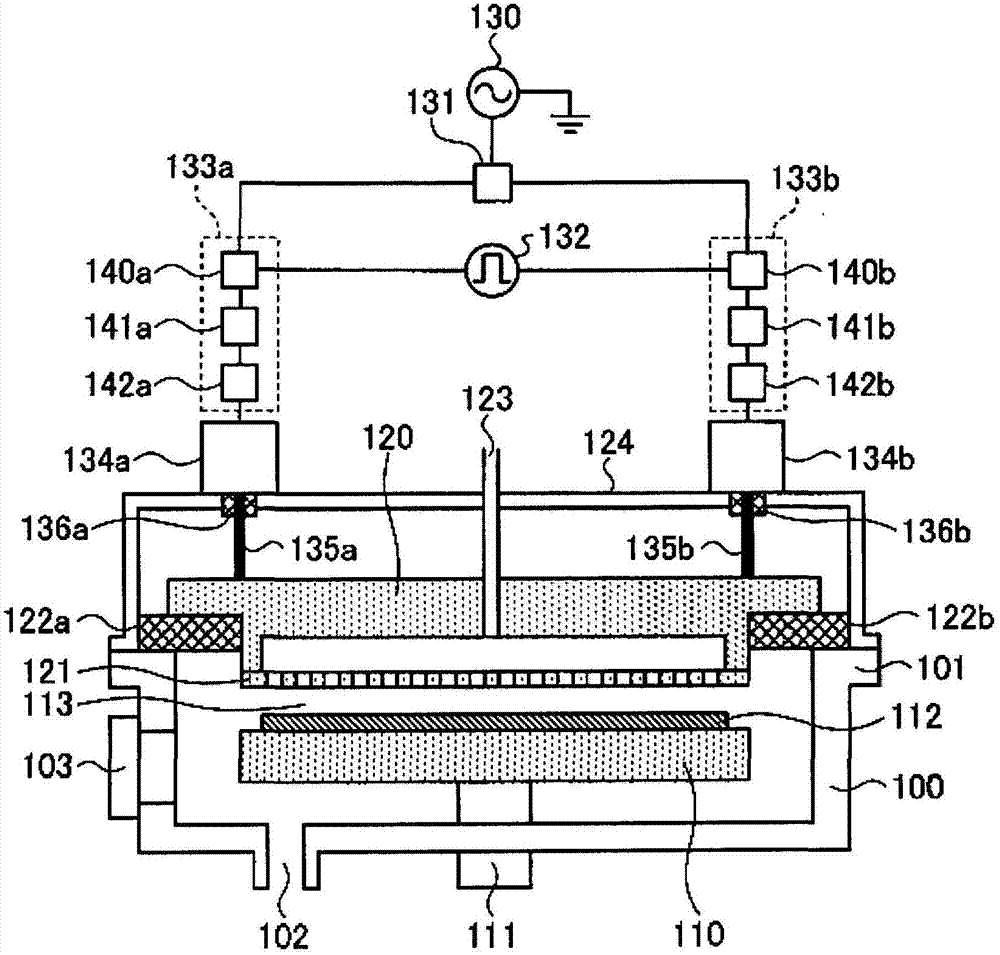

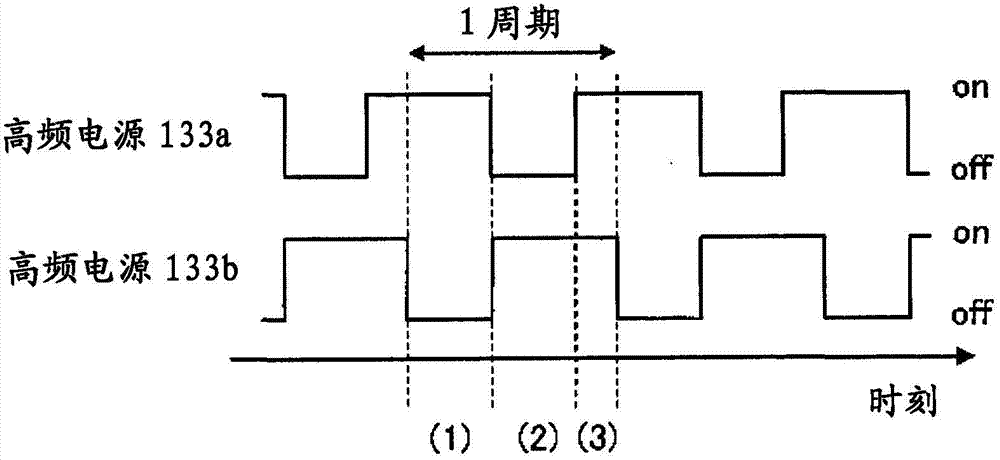

[0059] figure 1 It is a diagram schematically showing a configuration example of Embodiment 1 of the plasma processing apparatus of the present invention. like figure 1 As shown, the plasma processing apparatus of this embodiment is a plasma processing apparatus that generates plasma and forms a thin film by chemical vapor deposition, and includes a vacuum chamber 100, a stage 110 with a moving mechanism, and a plurality of gas supply ports. Shower plate 121, pulse generator (power switching unit) 132, high-frequency power sources (power sources) 133a and 133b capable of pulse modulation.

[0060] The vacuum chamber 100 is connected to the flange 101 and is airtightly sealed with the insulating gaskets 122a and 122b to separate the interior from the atmosphere. The insulating spacers 122a, 122b fix the electrode block 120 . These structures constitute a decompression container including a stage 110 and a shower plate 121 inside, and the space between the stage 110 and the s...

Embodiment approach 2

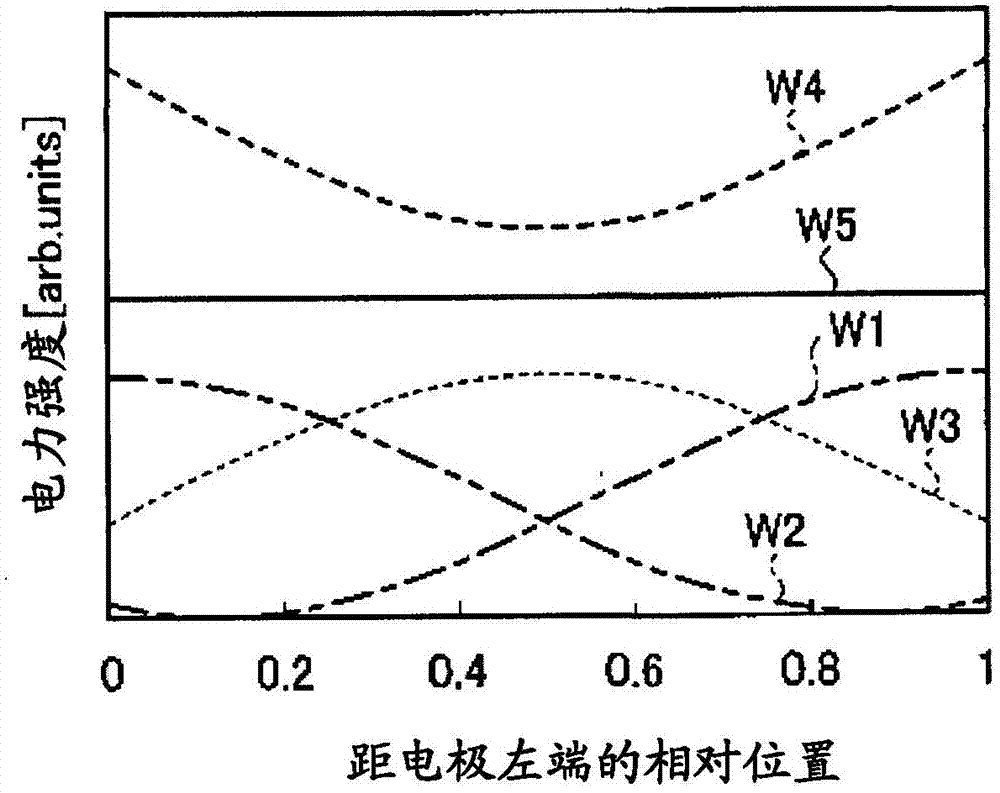

[0125] In Embodiment 1, the number of feeding points is 2 for description, but in the method suggested by the present invention, the number of feeding points may be greater than or equal to 2. Hereinafter, as another embodiment, a case where the number of feeding points is 4 or more will be described as an example of feeding at 2 or more points. The structure of the plasma processing apparatus of the present embodiment is different from the number of feed points (that is, four sets of high-frequency power supplies, matching devices, and feed rods are provided, and the pulse generator (power switching unit) 132 is used for supplying four high-frequency power supplies. The configuration is the same as that of Embodiment 1 except for the switched output signal). In addition, for the sake of simplicity, four points are set, and when the number of feeding points is greater than or equal to 3 or greater than or equal to 5, it can also be expanded according to the same thinking metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com