Holding body for flexible grinding means, and grinding system

A holding body and grinding technology, applied in the direction of machine tools suitable for grinding workpiece edges, grinding/polishing safety devices, grinding/polishing equipment, etc., to achieve cost-effective and simple manufacturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

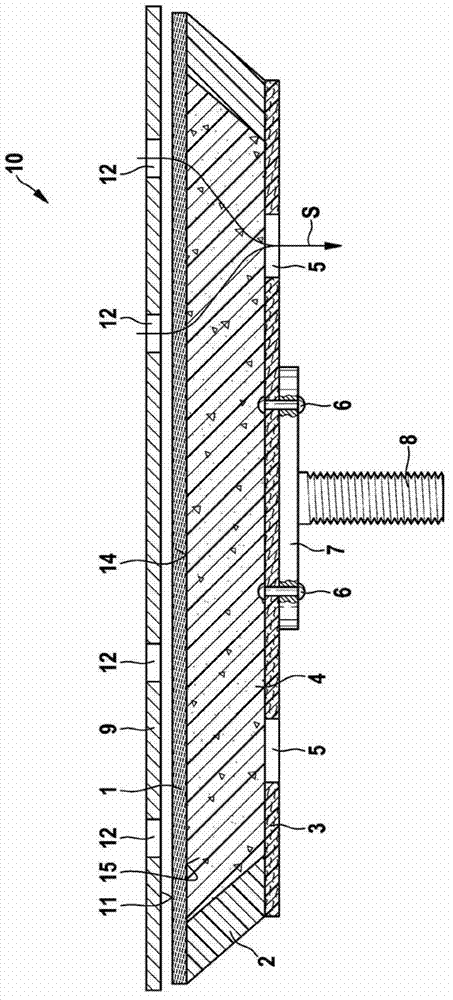

[0028] exist figure 1 A side sectional view of a holding body according to the invention, which forms the grinding disc 10 , is shown in FIG. The grinding disc 10 has a cover plate 3 made of fiberglass. The cover plate 3 comprises a plurality of suction holes 5 axially penetrating it, only two of which can be seen here. The cover plate 3 is connected to a metal plate 7 by means of rivets 6 . Fastened to the metal plate 7 is a screw 8 , by means of which the grinding disc 10 can be fastened to a rotary drive of a grinding machine (not shown here). The bolt 8 thus serves as a fastening means.

[0029] In other embodiments not shown here, the sheet metal 7 , the rivet 6 and the screw 8 are not part of the grinding disc 10 but are part of a machine-side receptacle for the grinding disc 10 . In this case, the cover plate 3 forms a fastening device for the grinding wheel 10 by means of which the grinding wheel 10 can be fixed to the drive.

[0030] The grinding wheel 10 has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com