Transverse laminated synchronous reluctance motor with auxiliary permanent magnets

A technology of synchronous reluctance motor and permanent magnet, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., and can solve the problem of narrow constant power speed regulation range , low power factor and other issues, to achieve the effect of widening the constant power speed regulation range, strong magnetic resistance torque, and high salient pole ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

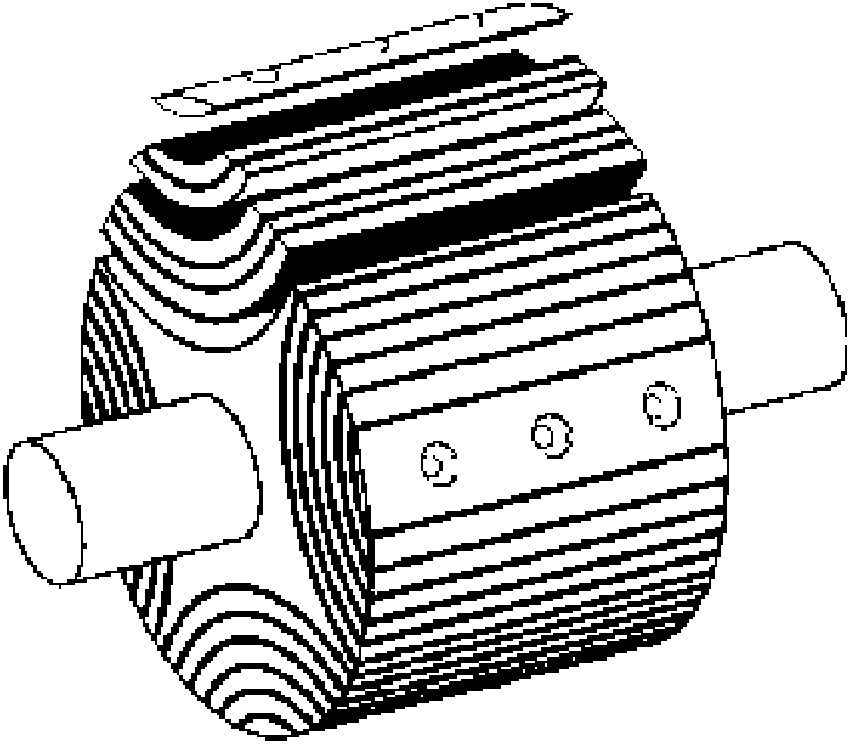

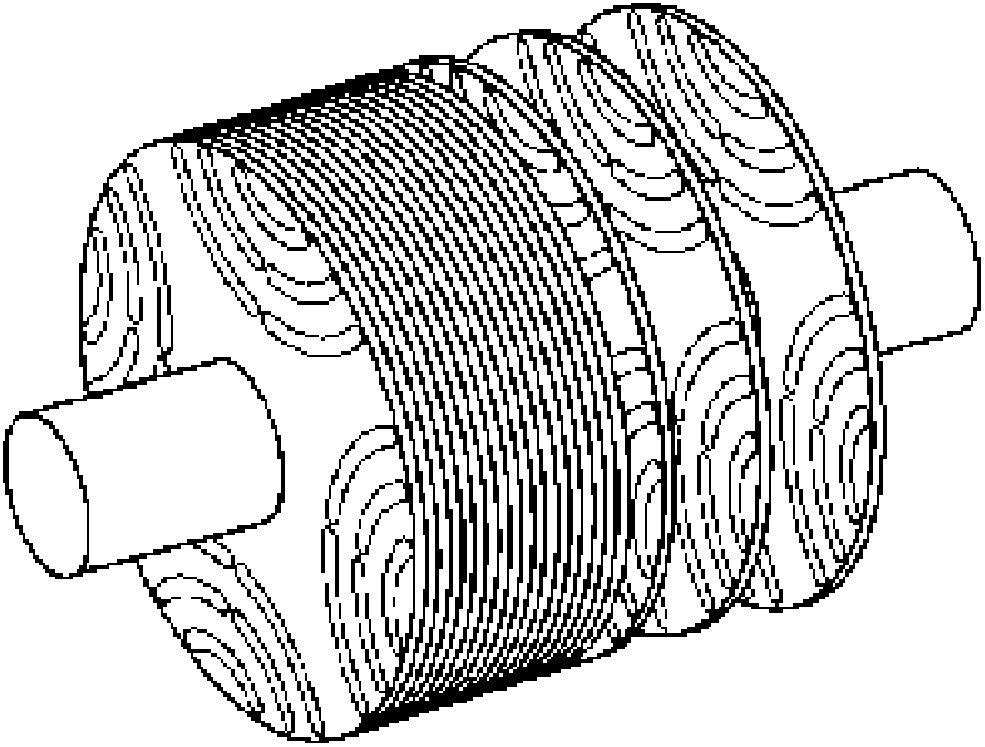

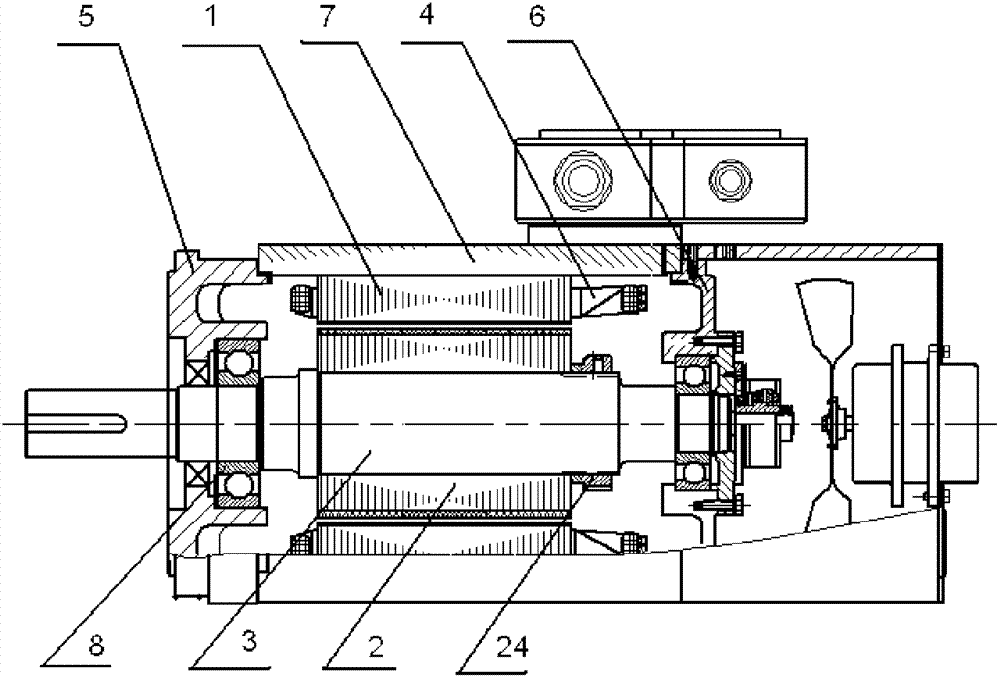

[0020] The horizontal laminated synchronous reluctance motor with auxiliary permanent magnet of the present invention is specifically as Figure 2-4 As shown, it includes a stator core 1, a stator winding 4, a rotor core assembly 2, a rotating shaft 3, a bearing 8 supporting the rotating shaft 3, a front end cover 5, a rear end cover 6 and a casing 7, wherein,

[0021] The rotor core assembly 2 includes a rotor core 21 sleeved on the rotating shaft 3 and a plurality of block-shaped permanent magnets 22. The rotor core 21 is formed by laminating multiple complete steel sheets with a single shape laterally along the rotating shaft 3. The rotor core 21 has multiple layers of arc slots 23 suitable for inserting block permanent magnets 22;

[0022] The block permanent magnet 22 is arranged in the above-mentioned arc groove 23, and the polarity of each permanent magnet 22 in each layer of arc groove 23 under the same pole is the same and forms a magnetic pole group, and the polarity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com